Question: Can someone please explain how you would do this in excel!!! 5. Consider the following information for the Fairmount Company: Production change cost = $20/unit

Can someone please explain how you would do this in excel!!!

Can someone please explain how you would do this in excel!!!

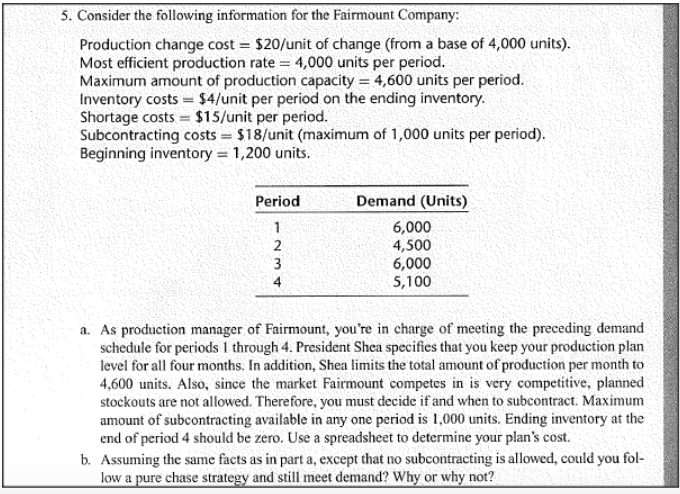

5. Consider the following information for the Fairmount Company: Production change cost = $20/unit of change (from a base of 4,000 units). Most efficient production rate 4,000 units per period Maximum amount of production capacity = 4,600 units per period. Inventory costs = $4/unit per period on the ending inventory. Shortage costs--$15/unit per period. Subcontracting costs $18/unit (maximum of 1,000 units per period). Beginning inventory = 1,200 units. Period Demand (Units) 6,000 4,500 6,000 5,100 2 4 a. As production manager of Fairmount, you're in charge of meeting the preceding demand schedule for periods 1 through 4. President Shea specifies that you keep your production plan level for all four months. In addition, Shea limits the total amount of production per month to 4,600 units. Also, since the market Fairmount competes in is very competitive, planned stockouts are not allowed. Therefore, you must decide if and when to subcontract. Maximum amount of subcontracting available in any one period is 1,000 units. Ending inventory at the end of period 4 should be zero. Use a spreadsheet to determine your plan's cost. b. Assuming the same facts as in part a, except that no subcontracting is allowed, could you fol low a pure chase strategy and still meet demand? Why or why not? 5. Consider the following information for the Fairmount Company: Production change cost = $20/unit of change (from a base of 4,000 units). Most efficient production rate 4,000 units per period Maximum amount of production capacity = 4,600 units per period. Inventory costs = $4/unit per period on the ending inventory. Shortage costs--$15/unit per period. Subcontracting costs $18/unit (maximum of 1,000 units per period). Beginning inventory = 1,200 units. Period Demand (Units) 6,000 4,500 6,000 5,100 2 4 a. As production manager of Fairmount, you're in charge of meeting the preceding demand schedule for periods 1 through 4. President Shea specifies that you keep your production plan level for all four months. In addition, Shea limits the total amount of production per month to 4,600 units. Also, since the market Fairmount competes in is very competitive, planned stockouts are not allowed. Therefore, you must decide if and when to subcontract. Maximum amount of subcontracting available in any one period is 1,000 units. Ending inventory at the end of period 4 should be zero. Use a spreadsheet to determine your plan's cost. b. Assuming the same facts as in part a, except that no subcontracting is allowed, could you fol low a pure chase strategy and still meet demand? Why or why not

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts