Question: Can you help me in this case study. Question A: Stay Safe International manufactures industrial safety equipment at its plant in Evans- ville, Indiana. The

Can you help me in this case study.

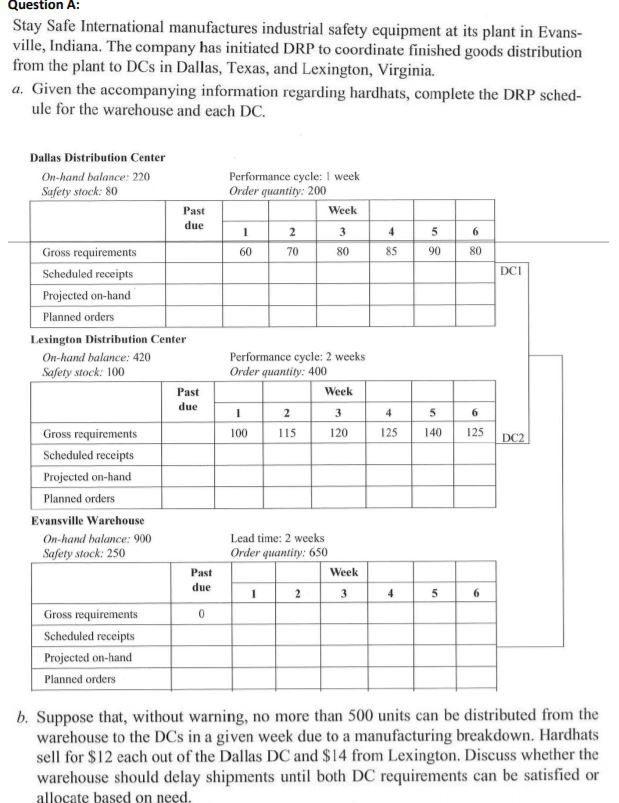

Question A: Stay Safe International manufactures industrial safety equipment at its plant in Evans- ville, Indiana. The company has initiated DRP to coordinate finished goods distribution from the plant to DCs in Dallas, Texas, and Lexington, Virginia. a. Given the accompanying information regarding hardhats, complete the DRP sched- ule for the warehouse and each DC. Dallas Distribution Center On-hand balance: 220 Performance cycle: I week Safety stock: 80 Order quantity: 200 Past Week due 2 3 5 6 Gross requirements 60 70 80 85 90 80 Scheduled receipts DCI Projected on-hand Planned orders Lexington Distribution Center On-hand balance: 420 Performance cycle: 2 weeks Safety stock: 100 Order quantity: 400 Past Week due 2 3 5 Gross requirements 100 115 120 125 140 125 DC2 Scheduled receipts Projected on-hand Planned orders Evansville Warehouse On-hand balance: 900 Lead time: 2 weeks Safety stock: 250 Order quantity: 650 Past Week due 2 3 4 5 6 Gross requirements 0 Scheduled receipts Projected on-hand Planned orders b. Suppose that, without warning, no more than 500 units can be distributed from the warehouse to the DCs in a given week due to a manufacturing breakdown. Hardhats sell for $12 each out of the Dallas DC and $14 from Lexington. Discuss whether the warehouse should delay shipments until both DC requirements can be satisfied or allocate based on need

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts