Question: Capacity Planning practice problems 1 and 2. The following problem uses the Capacity Planning using Overall Factors (CPOF) method. This is the least complex of

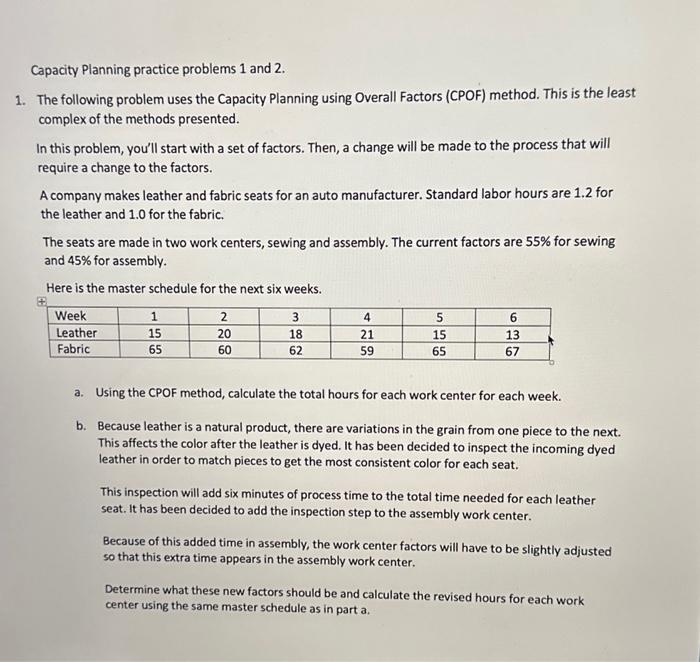

Capacity Planning practice problems 1 and 2. The following problem uses the Capacity Planning using Overall Factors (CPOF) method. This is the least complex of the methods presented. In this problem, you'll start with a set of factors. Then, a change will be made to the process that will require a change to the factors. A company makes leather and fabric seats for an auto manufacturer. Standard labor hours are 1.2 for the leather and 1.0 for the fabric. The seats are made in two work centers, sewing and assembly. The current factors are 55% for sewing and 45% for assembly. Here is the master schedule for the next six weeks. a. Using the CPOF method, calculate the total hours for each work center for each week. b. Because leather is a natural product, there are variations in the grain from one piece to the next. This affects the color after the leather is dyed. It has been decided to inspect the incoming dyed leather in order to match pieces to get the most consistent color for each seat. This inspection will add six minutes of process time to the total time needed for each leather seat. It has been decided to add the inspection step to the assembly work center. Because of this added time in assembly, the work center factors will have to be slightly adjusted so that this extra time appears in the assembly work center. Determine what these new factors should be and calculate the revised hours for each work center using the same master schedule as in part a

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts