Question: Capacity Utilization Analysis A manufacturing plant p r 2 oduces electronic components for industrial machines. The plant operates 2 2 working days per month. A

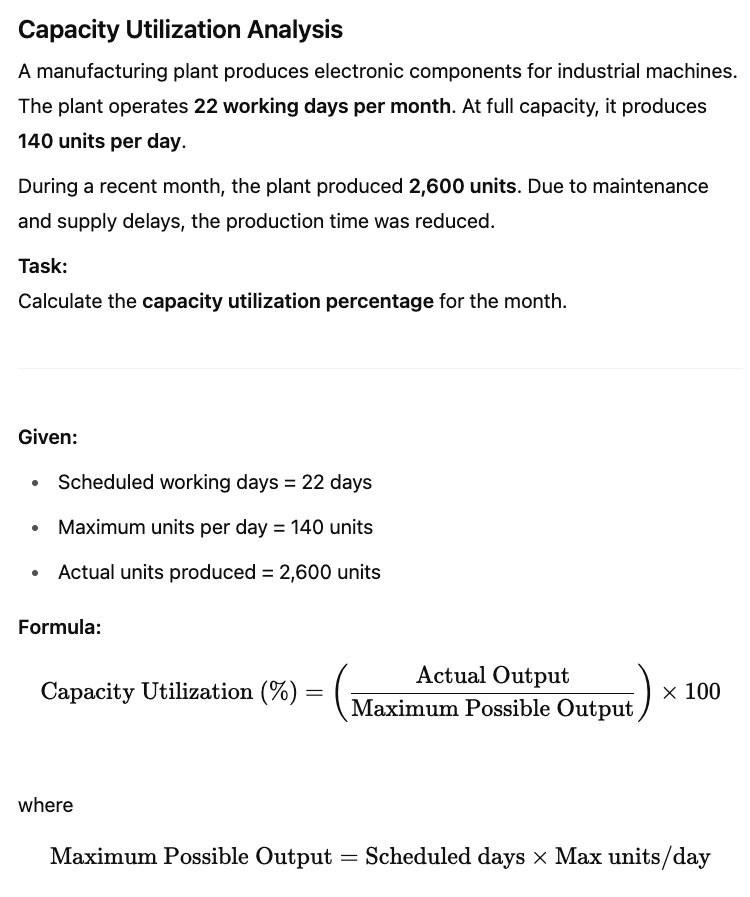

Capacity Utilization Analysis

A manufacturing plant oduces electronic components for industrial machines.

The plant operates working days per month. full capacity, produces

units per day.

During a recent month, the plant produced units. Due maintenance

and supply delays, the production time was reduced.

Task:

Calculate the capacity utilization percentage for the month.

Given:

Scheduled working days days

Maximum units per day units

Actual units produced units

Formula:

Capacity Utilization

where

Maximum Possible Output Scheduled days Max units day Average Inventory Level Calculation

A company orders units a spare part each time replenishes inventory.

The annual demand for the part units.

Task:

Calculate the average inventory level the company holds over the year.

Given:

Annual demand units

Order quantity units

Formula:

Average Inventory

Production Cycle Time

A factory produces metal sheets. Each production run produces sheets

and takes hours. After each run, the machine requires hours setup

before starting the next run.

Task: Task:

Calculate the production cycle time for one run including setup.

Given:

Production run time hours

Setup time hours

Formula:

Production Cycle Time Production Run Time Setup Time

Labor Productivity

assembly line produces units per hour shift using workers.

Task:

Calculate the labor productivity units per worker per hour.

Given:

Total units produced units

Shift length hours Number workers

Formula:

Labor Productivity

Machine Utilization Process Flowchart Flowchart

A manufacturing facility's machine available for production hours per day.

The machine's actual run time varies due setup, maintenance, and downtime.

Management wants understand the process measuring and reporting

machine utilization.

Task:

Draw a process flowchart showing the steps involved tracking machine

utilization for a typical day. The flowchart should include:

Start the day and machine availability check

Recording available machine hours

Recording actual machine run time

Logging downtime reasons setup, maintenance, breakdown

Calculating and reporting utilization a process step, math neede

End process

Operation management

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock