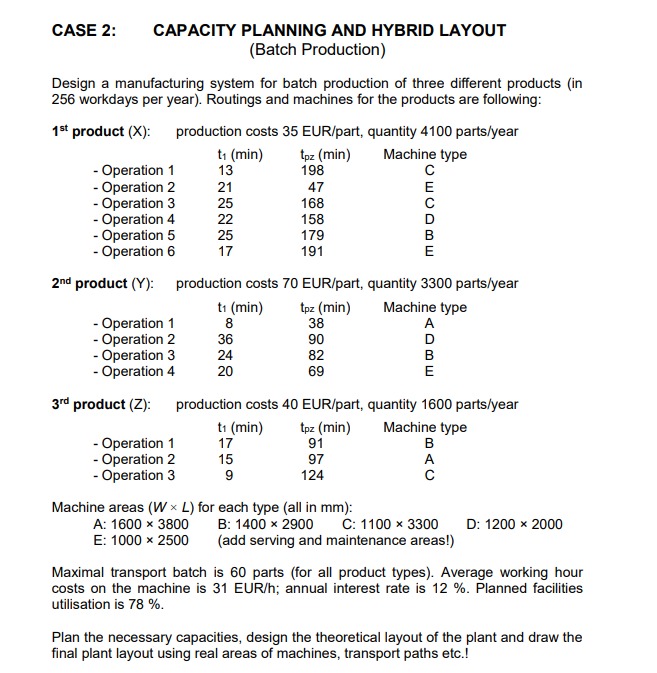

Question: CASE 2 : CAPACITY PLANNING AND HYBRID LAYOUT ( Batch Production ) Design a manufacturing system for batch production of three different products ( in

CASE :

CAPACITY PLANNING AND HYBRID LAYOUT

Batch Production

Design a manufacturing system for batch production of three different products in

workdays per year Routings and machines for the products are following:

product : production costs EURpart quantity partsyear

product : production costs EURpart quantity partsyear

product : production costs EURpart quantity partsyear

Machine areas for each type all in :

A:

B:

C:

D:

:

add serving and maintenance areas!

Maximal transport batch is parts for all product types Average working hour

costs on the machine is ; annual interest rate is Planned facilities

utilisation is

Plan the necessary capacities, design the theoretical layout of the plant and draw the

final plant layout using real areas of machines, transport paths etc.!

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock