Question: Case: Chipotles Quality Problems Scenario: You are sitting in your consultancys conference room, trying to grasp how one of the worlds hottest brands just took

Case: Chipotles Quality Problems

Scenario: You are sitting in your consultancys conference room, trying to grasp how one of the worlds hottest brands just took a dive into freezing water. Your team members are promoting their ideas on how you should lead a meeting with Chipotle leadership, which is only three days away. For just a moment, you zone out, trying to assimilate the facts, going back to the beginning. Over 20 years ago, Chipotle Mexican Grill set out to raise the bar in delivering fresh, sustainable, locally sourced food to U.S. customers. Chipotle grew rapidly, establishing 2,000 restaurants, earning customer trust, and gaining notoriety as the best Mexican grill in America. Chipotles motto, food with integrity and its commitment to transparent product sourcing had made it the biggest name in the rapidly growing fast casual segment. Industry experts had predicted Chipotle would surpass McDonalds in terms of number of stores in the U.S. Then Chipotle suffered a supply shortage. One of its pork suppliers was violating Chipotles animal welfare standards. Unable to find a viable substitute supplier, Chipotle was forced to pull carnitasone of its most popular menu itemsfrom menus across the country. Who knew that a food-with-integrity strategy would become a limit to growth. Worse, only a few months later, over 500 customers in a dozen states came down with e Coli, norovirus, and salmonella food poisoning. Suddenly, Chipotles food-with-integrity strategy had become a real liability. In fact, the blowback was startling not only in its breadth but also in its ferocity. Sales in stores open at least a year sank 14.6%. Profits plunged 44%down from $121.2 million to $67.9 million (from $3.91 per share to $2.17 a share) compared with the same quarter the previous year. The cost of new food safety equipment, testing to determine the cause of the problems, hiring auditors and consultants, and training employees in new procedures had reduced profit margins by more than 8%. A group of Chipotle shareholders filed a federal lawsuit accusing executives of failing to establish quality-control and emergency-response measures to prevent and then stop food-borne illnesses that sickened customers across the country and proved costly to the company. A new marketing and promotional campaign cost the Chipotle $50 million - three times more than Chipotle had spent on such programs in the previous year. Chipotle had never spent more on a marketing campaign. Trying to recover from the crisis, Chipotle announced what it described as a pioneering safety program. The program was extensive. More ingredients would be prepared in central kitchens rather than in restaurants. For instance, lettuce would be cleaned and cheese grated in carefully controlled, centralized processing center. Similarly, onions, jalapeos, and other vegetables that arrive in the restaurant whole would be blanched in boiling water to kill microbes. Chipotle would put greater scrutiny on suppliers, requiring DNA-based testing of ingredients before they are shipped to restaurants. This program would far exceed industry standards and regulatory requirements. Chipotle committed $10 million to help suppliers meet its new standards. Any supplier that was unwilling to meet the requirements would be dropped from Chipotles approved supplier list. Chipotle would increase employee training to ensure employees could comply with the companys food safety standards. End-of-shelf-life testing would take place to ensure quality specifications are maintained throughout the ingredients shelf life. No one at Chipotle has publicly estimated the cost of the safety program. Everyone simply called it, Very, very expensive! Although food safety experts commended Chipotles efforts, they warned that, Its kind of hard to test your way to food safety. Bob Whitaker, chief science and technology officer of the Produce Marketing Association (PMA), says that, Typically, contamination occurs very infrequently and is not uniform, and the levels are very low, so the odds of isolating that product randomly are very small. You blink, forcing yourself back into the moment. As you look at the reports your team has compiled, you notice the folder titled, Total Quality Management. It contains the hard copy material from your most recent continuing education course on quality management. You wonder, Could some of the concepts I learned in that course be helpful? If so, which ones are most important?

Questions:

1.Describe Chipotles customers in terms of the appropriate dimensions of quality. Which ones are most important?

2.Describe how the concept of quality at the source affects Chipotles food safety crisis.

3.Assess Chipotles cost of quality. Be sure to evaluate all four categories.

4.Considering the eight principles of TQM, which principles did Chipotle most likely violate? Which principles will be most important moving forward?

5.Given Bob Whitakers comment, how do the concepts of common and special cause variation become more challenging when it comes to food safety? What are the unique challenges to Chipotles new pioneering food safety strategy?

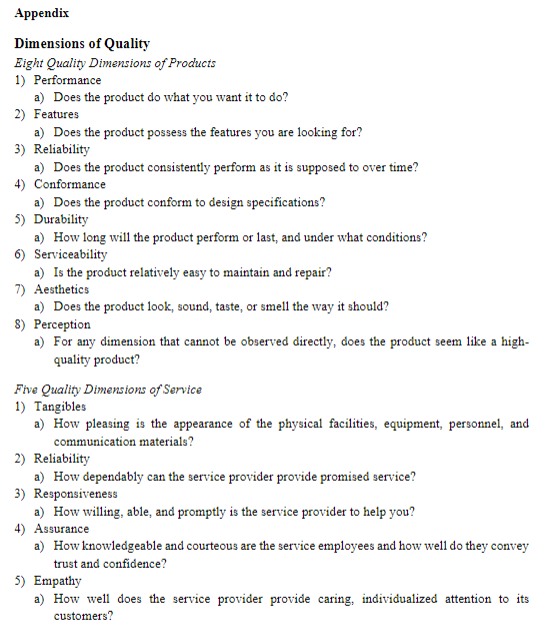

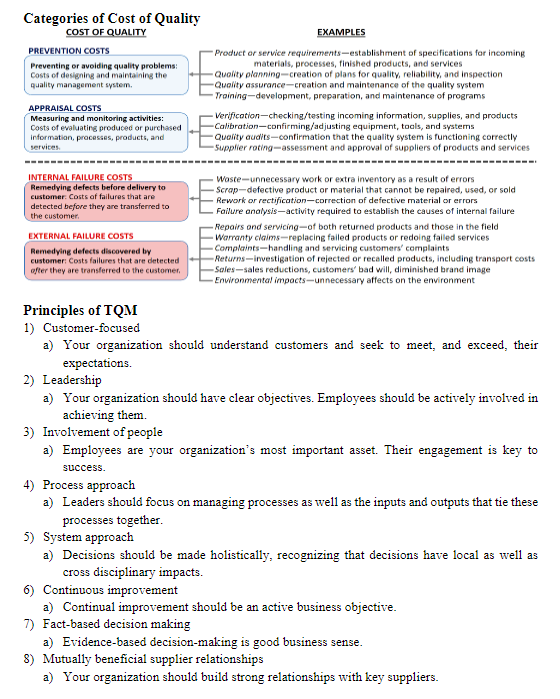

Appendix Dimensions of Quality Eight Quality Dimensions of Products 1) Performance a) Does the product do what you want it to do? 2) Features a) Does the product possess the features you are looking for? 3) Reliability a) Does the product consistently perform as it is supposed to over time? 4) Conformance a) Does the product conform to design specifications? 5) Durability a) How long will the product perform or last, and under what conditions? 6) Serviceability a) Is the product relatively easy to maintain and repair? 7) Aesthetics a) Does the product look, sound, taste, or smell the way it should? 8) Perception a) For any dimension that cannot be observed directly, does the product seem like a high- quality product? Five Quality Dimensions of Service 1) Tangibles a) How pleasing is the appearance of the physical facilities, equipment, personnel, and communication materials? 2) Reliability a) How dependably can the service provider provide promised service? 3) Responsiveness a) How willing, able, and promptly is the service provider to help you? 4) Assurance a) How knowledgeable and courteous are the service employees and how well do they convey trust and confidence? 5) Empathy a) How well does the service provider provide caring, individualized attention to its customers? EXAMPLES Categories of Cost of Quality COST OF QUALITY PREVENTION COSTS Preventing or avoiding quality problems Costs of designing and maintaining the quality management system. Product or service requirements--establishment of specifications for incoming materials, processes, finished products, and services Quality planning-creation of plans for quality, reliability, and inspection Quality assurance-creation and maintenance of the quality system Training-development, preparation, and maintenance of programs Verification-checking/testing incoming information, supplies, and products Calibration-confirming/adjusting equipment, tools, and systems Quality audits-confirmation that the quality system is functioning correctly - Supplier roting-assessment and approval of suppliers of products and services APPRAISAL COSTS Measuring and monitoring activities: Costs of evaluating produced or purchased information processes, products, and services INTERNAL FAILURE COSTS Remedying defects before delivery to customer costs af failures that are detected before they are transferred to the customer. Waste- unnecessary work or extra inventory as a result of errors Scrap-defective product or material that cannot be repaired, used, or sold Rework or rectification-correction of defective material or errors Failure analysis-activity required to establish the causes of internal failure Repairs and servicing-of both returned products and those in the field Warranty claims-replacing failed products or redoing failed services Complaints-handling and servicing customers' complaints -Returns-investigation of rejected or recalled products, including transport costs -Sales-sales reductions, customers' bad will, diminished brand image Environmental impacts-unnecessary affects on the environment EXTERNAL FAILURE COSTS Remedying defects discovered by customer: Costs failures that are detected after they are transferred to the customer Principles of TQM 1) Customer-focused a) Your organization should understand customers and seek to meet, and exceed, their expectations. 2) Leadership a) Your organization should have clear objectives. Employees should be actively involved in achieving them. 3) Involvement of people a) Employees are your organization's most important asset. Their engagement is key to success. 4) Process approach a) Leaders should focus on managing processes as well as the inputs and outputs that tie these processes together. 5) System approach a) Decisions should be made holistically, recognizing that decisions have local as well as cross disciplinary impacts. 6) Continuous improvement a) Continual improvement should be an active business objective. 7) Fact-based decision making a) Evidence-based decision-making is good business sense. 8) Mutually beneficial supplier relationships a) Your organization should build strong relationships with key suppliers

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts