Question: Case Nick Talbot had a problem. As the master planner for Hardy Custom Engraving, he was responsible for ensuring that they meet the sometimes conflicting

Case

Nick Talbot had a problem. As the master planner for Hardy Custom Engraving, he was responsible for ensuring that they meet the sometimes conflicting priorities of sales, production, and finance. Something has gone terribly wrong, and all Nick's plans have failed. Despite his best efforts to level production and still meet promised delivery dates, two customers will not be getting their shipments this week. Jim "Buster" Hush had just pointed out the obvious by declaring in front of everyone in the meeting that, "You should have seen it coming!!", but Nick couldn't see how.

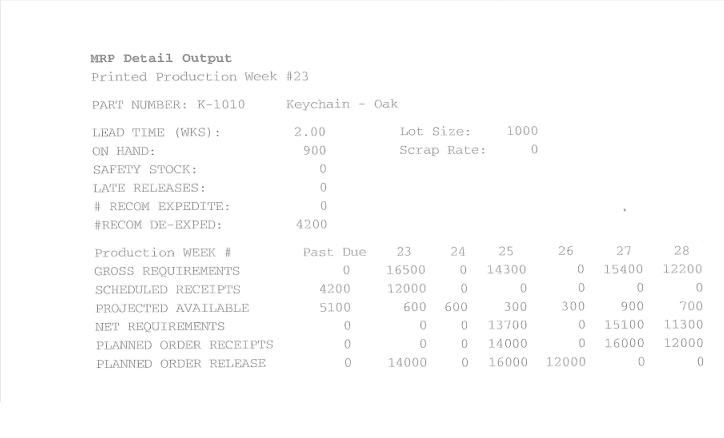

Nick stared at the latest output from the MRP system on his desk for K-1010, the product that was ruining his career. How could things have gone so wrong in two weeks? When Leona Hardy had taken over the company from her father, she came with some new ideas, many of which were already paying big dividends, and the company was really starting to grow. One of these ideas was the introduction of wood products to the existing line of metal fabricated items. There is no arguing that the line is proving popular with customers (and the sales force) resulting in higher revenues and profits. Demand for K-1010 is a perfect example of this. Who would have thought that there was such a big market for laser engraved hardwood key chains? Well, the report told the tale.

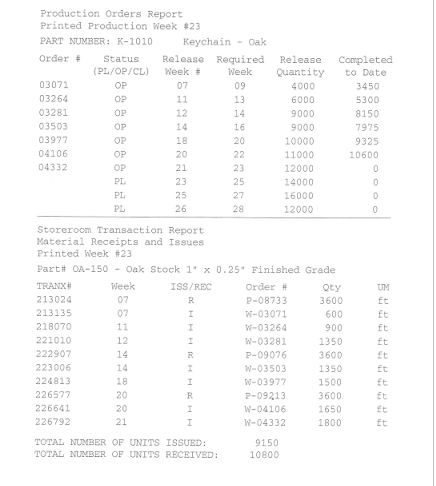

Hardy had been selling the new key chains for the last 15 weeks or so. Demand started slow but grew steadily. Everything had been going according to plan. There had been no problems with the supplier of the oak stock from which the key chains were cut. The line had reported no problems. No shortages, no production problems, but no finished goods when the system was telling him there should be ample coverage for the current customer orders. They just weren't there.

When he first got wind of the problem, Nick had thought that sales might be up to their old tricks of booking new business inside the frozen zone. He had floated that in the meeting without giving it much thought. That had really lit Buster's fuse. Buster was adamant that no new orders were being booked inside the lead time for the key chains. He had already heard from Leona that those kinds of actions were not going to be tolerated. He remembered her distinctly saying, "This is a new product line and we wanted to make sure that we don't start off by making promises we can't keep." Buster knew it wouldn't be wise to test her on this (at least not right away), so he had instructed all his reps to pay very close attention to the available-to-promise values. He knew if there were any arguments down the line, he could claim he depended on the information system.

In looking at the MRP record, Nick wondered why there were no material shortages for the oak stock. He knew that there were occasional knots and offcuts that meant that there should have been some scrap or yield issues but there was no scrap factor for the key chains. How was it that no material usage variances were being reported? He reviewed the issues of the oak stock from stores over the last couple of months hoping that would give him some clue. While future products would use oak, the key chains are currently the only product to use it, at a rate of 15 linear feet per 100 key chains. The latest cycle count, taken this morning, showed 1650 linear feet of oak on the shelf.

questions:

- Is the MRP working correctly?Why or Why not? Hint: Does the Storeroom Transaction Report match the current raw material inventory?

- From the Production Orders Report calculate the average scrap rate.

- Would you order more raw materials?If no, why not?If yes, how much and when?

- Would you consider safety stock?Explain.

- Consider the following:

- What is causing the poor customer service?

- What can be done immediately to resolve the customer service issue?

- What changes can be made to the system to avoid these problems long term?

A detailed explanation of how the MRP is functioning

Discuss issues such as customer service, scrap rates, and safety stock

Should a raw material order be placed?

What is the main issue and what caused it?

What can be done right now to help improve the situation?

What can be done to fix the issues for the long term?

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts