Question: Case on Process Costing, Operation Costing, Impact on Resource Allocation Decision different models using purchased parts such as pulley assemblies, weight adjustment bolts, side plates,

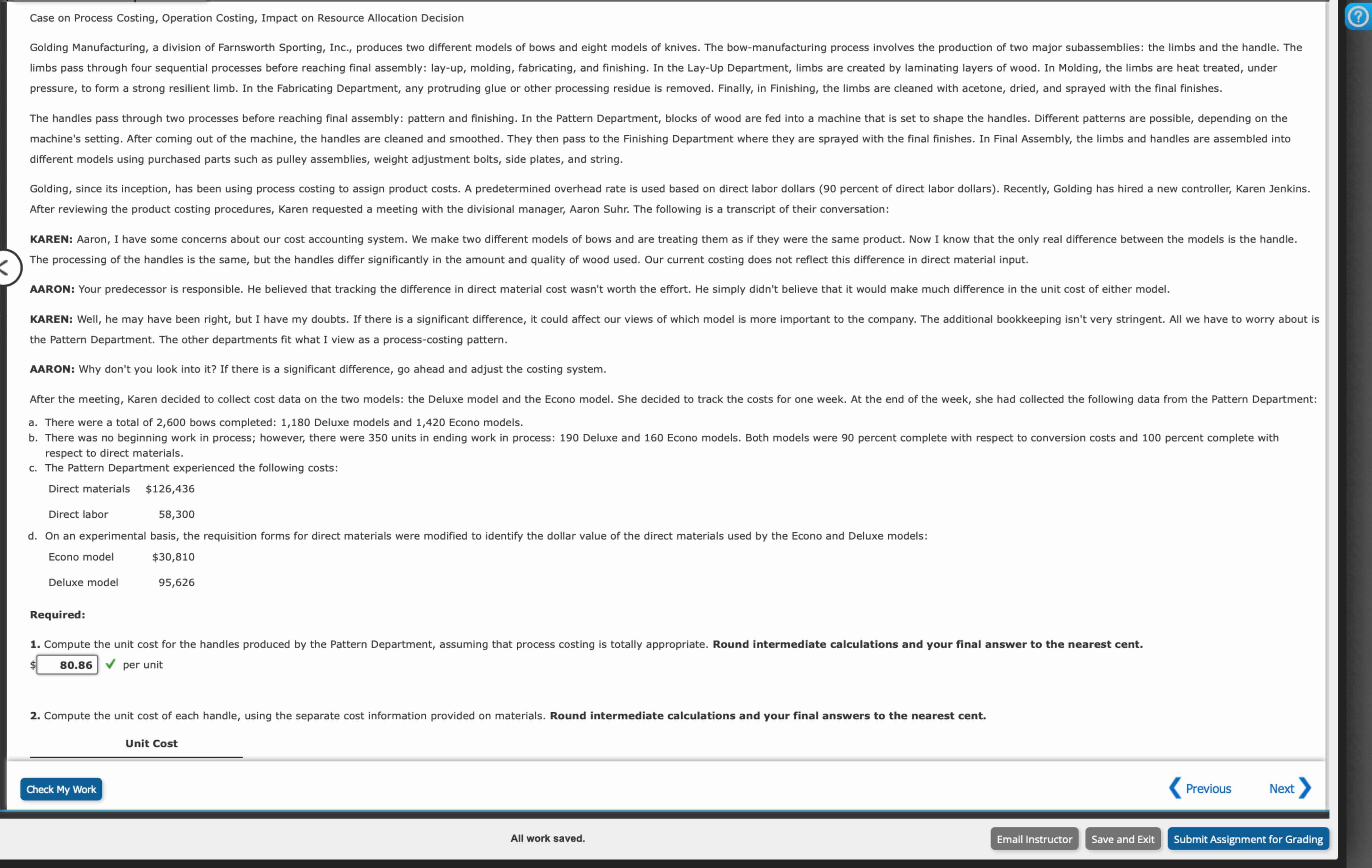

Case on Process Costing, Operation Costing, Impact on Resource Allocation Decision different models using purchased parts such as pulley assemblies, weight adjustment bolts, side plates, and string. After reviewing the product costing procedures, Karen requested a meeting with the divisional manager, Aaron Suhr. The following is a transcript of their conversation: The processing of the handles is the same, but the handles differ significantly in the amount and quality of wood used. Our current costing does not reflect this difference in direct material input. the Pattern Department. The other departments fit what I view as a processcosting pattern.

AARON: Why don't you look into it If there is a significant difference, go ahead and adjust the costing system.

a There were a total of bows completed: Deluxe models and Econo models. respect to direct materials.

c The Pattern Department experienced the following costs:

Direct materials $

Direct labor quad

d On an experimental basis, the requisition forms for direct materials were modified to identify the dollar value of the direct materials used by the Econo and Deluxe models:

Econo model $

Deluxe model

Required:

$

checkmark per unit

Compute the unit cost of each handle, using the separate cost information provided on materials. Round intermediate calculations and your final answers to the nearest cent.

Unit Cost different models using purchased parts such as pulley assemblies, weight adjustment bolts, side plates, and string. After reviewing the product costing procedures, Karen requested a meeting with the divisional manager, Aaron Suhr. The following is a transcript of their conversation: The processing of the handles is the same, but the handles differ significantly in the amount and quality of wood used. Our current costing does not reflect this difference in direct material input. the Pattern Department. The other departments fit what I view as a processcosting pattern.

AARON: Why don't you look into it If there is a significant difference, go ahead and adjust the costing system.

a There were a total of bows completed: Deluxe models and Econo models. respect to direct materials.

c The Pattern Department experienced the following costs:

Direct materials $

Direct labor

d On an experimental basis, the requisition forms for direct materials were modified to identify the dollar value of the direct materials used by the Econo and Deluxe models:

Econo model $

Deluxe model

Required:

checkmark per unit

Compute the unit cost of each handle, using the separate cost information provided on materials. Round intermediate calculations and your final answers to the nearest cent.

Unit Cost

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock