Question: CASE STUDIES De Mar's Product Strategy De Mar, a plumbing, heating, and air-conditioning company De Mar uses selective hiring, ongoing training and education, located in

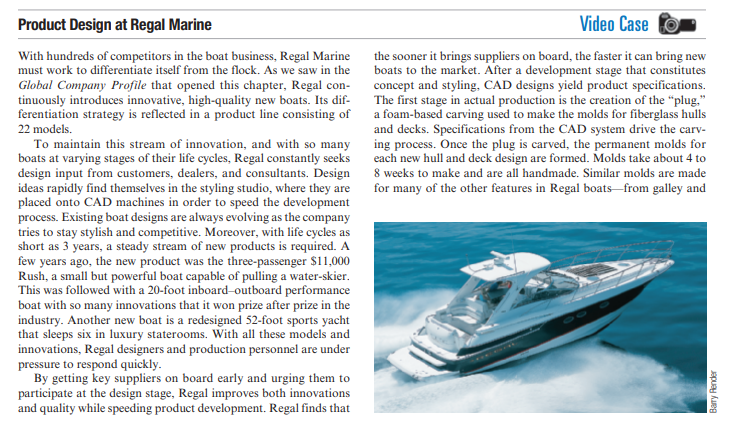

CASE STUDIES De Mar's Product Strategy De Mar, a plumbing, heating, and air-conditioning company De Mar uses selective hiring, ongoing training and education, located in Fresno, California, has a simple but powerful prod performance measures, and compensation that incorporate cus- uct strategy: Solve the customer's problem no matter what, solve tomer satisfaction, strong teamwork, peer pressure, empower- the problem when the customer needs it solved, and make sure the ment, and aggressive promotion to implement its strategy. Says customer feels good when you leave. De Mar offers guaranteed, credit manager Anne Semrick: "The person who wants a nine-to- same-day service for customers requiring it. The company pro five job needs to go somewhere else." vides 24-hour-a-day, 7-day-a-week service at no extra charge for De Mar is a premium pricer. Yet customers respond because customers whose air conditioning dies on a hot summer Sunday De Mar delivers valuethat is, benefits for costs. In 8 years, or whose toilet overflows at 2:30 A.M. As assistant service coor annual sales increased from about $200,000 to more than dinator Janie Walter puts it: We will be there to fix your A/C on $3.3 million. the fourth of July, and it's not a penny extra. When our competi- tors won't get out of bed, we'll be there!" Discussion Questions De Mar guarantees the price of a job to the penny before the work begins. Whereas most competitors guarantee their work for 1. What is De Mar's product? Identify the tangible parts of this 30 days, De Mar guarantees all parts and labor for one year. The product and its service components. company assesses no travel charge because it's not fair to charge 2. How should other areas of De Mar (marketing, finance, per- customers for driving out." Owner Larry Harmon says: We are sonnel) support its product strategy? in an industry that doesn't have the best reputation. If we start 3. Even though De Mar's product is primarily a service product, making money our main goal, we are in trouble. So I stress cus how should each of the 10 strategic OM decisions in the text be tomer satisfaction; money is the by-product." managed to ensure that the product is successful? Source: Reprinted with the permission of The Free Press, from On Great Service: A Framework for Action by Leonard L. Berry. Product Design at Regal Marine Video Case With hundreds of competitors in the boat business, Regal Marine the sooner it brings suppliers on board, the faster it can bring new must work to differentiate itself from the flock. As we saw in the boats to the market. After a development stage that constitutes Global Company Profile that opened this chapter, Regal con concept and styling, CAD designs yield product specifications. tinuously introduces innovative, high-quality new boats. Its dif The first stage in actual production is the creation of the "plug," ferentiation strategy is reflected in a product line consisting of a foam-based carving used to make the molds for fiberglass hulls 22 models. and decks. Specifications from the CAD system drive the carv- To maintain this stream of innovation, and with so many ing process. Once the plug is carved, the permanent molds for boats at varying stages of their life cycles, Regal constantly seeks each new hull and deck design are formed. Molds take about 4 to design input from customers, dealers, and consultants. Design 8 weeks to make and are all handmade. Similar molds are made ideas rapidly find themselves in the styling studio, where they are for many of the other features in Regal boats-from galley and placed onto CAD machines in order to speed the development process. Existing boat designs are always evolving as the company tries to stay stylish and competitive. Moreover, with life cycles as short as 3 years, a steady stream of new products is required. A few years ago, the new product was the three-passenger $11,000 Rush, a small but powerful boat capable of pulling a water-skier. This was followed with a 20-foot inboard-outboard performance boat with so many innovations that it won prize after prize in the industry. Another new boat is a redesigned 52-foot sports yacht that sleeps six in luxury staterooms. With all these models and innovations, Regal designers and production personnel are under pressure to respond quickly. By getting key suppliers on board early and urging them to participate at the design stage, Regal improves both innovations and quality while speeding product development. Regal finds that Barry Pender 228 PART 2 DESIGNING OPERATIONS stateroom components to lavatories and steps. Finished molds can be joined and used to make thousands of boats. Discussion Questions 1. How does the concept of product life cycle apply to Regal Marine products? 2. What strategy does Regal use to stay competitive? 3. What kind of engineering savings is Regal achieving by using CAD technology rather than traditional drafting techniques? 4. What are the likely benefits of the CAD design technology? *You may wish to view the video accompanying this case before addressing these questions