Question: Case Study 1 Dream It, Design It, 3D Print It Have you ever lost a beloved pet? No worries, just draw a picture of your

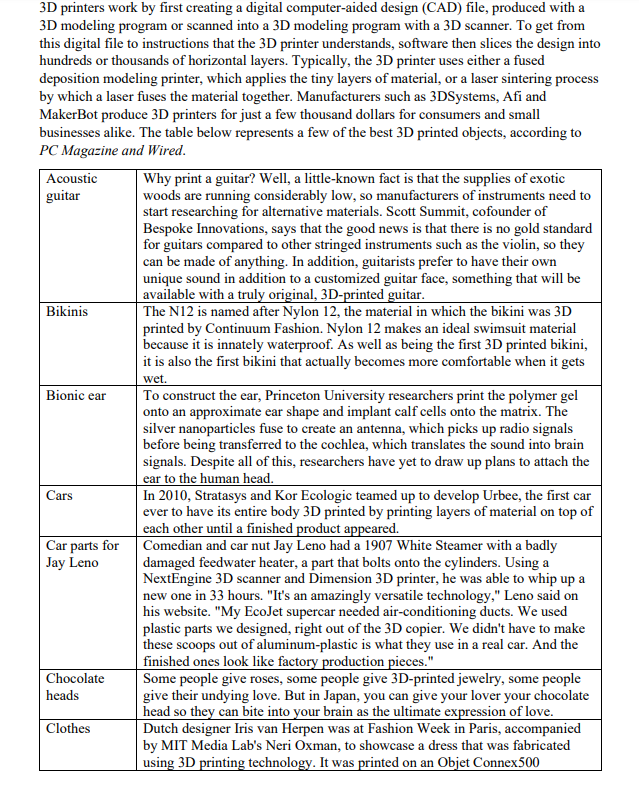

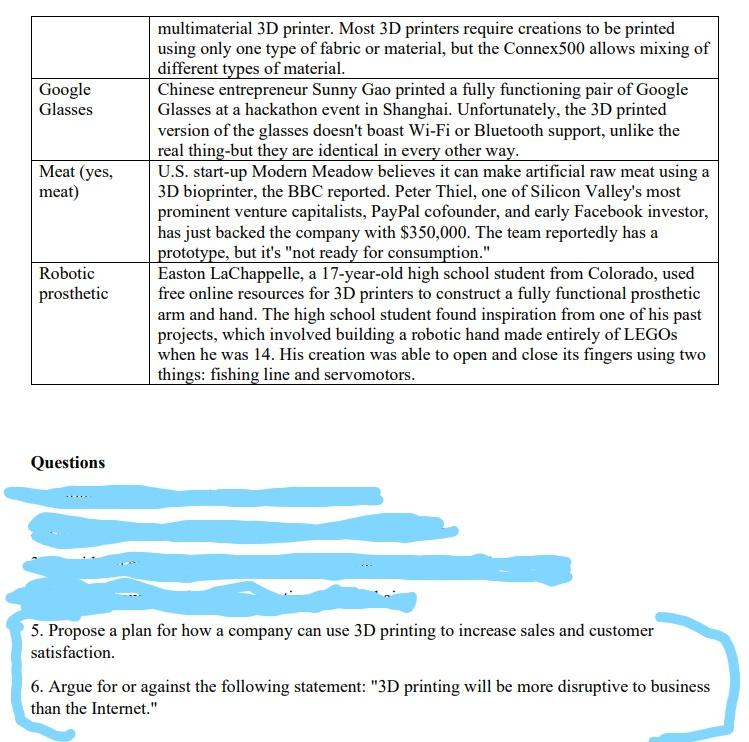

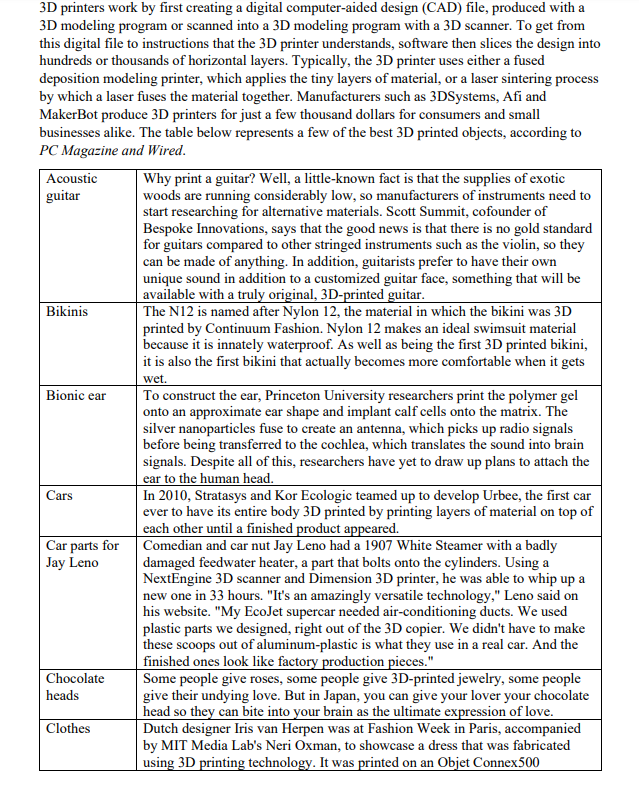

Case Study 1 Dream It, Design It, 3D Print It Have you ever lost a beloved pet? No worries, just draw a picture of your pet and print a plastic replica from your 3D desktop printer so your cat or dog can sit on your desk forever. Can you imagine printing your drawing in 3D? Well, there is no need to imagine this because you can do it today for as little as $300. Just think of all the problems you can solve by having your own 3D printer. Did you recently lose the key to your car's roof rack? No worries, just download the specifications and print one. Did you forget your girlfriend's birthday? No worries, just download and customize a silver bracelet with her initials, and in less than 30 minutes, you'll have the beautiful custom piece of jewelry on her wrist-without ever leaving your apartment. Welcome to the wonderful world of 3D printing. For almost 30 years, 3D printing has been used by large manufacturing companies to create everything from custom parts to working prototypes. The medical industry uses 3D printing to create custom hearing aids, artificial limbs, and braces, and art designers and architects use 3D printers to create models and prototypes of statues and buildings. Traditionally, 3D printing was only available to large corporations and engineers who could code the intricate devices. Today, the first generation of consumer 3D printers is hitting the market at affordable prices with software easy enough for children to use. The disruption occurring in the 3D printing world can, of course, be attributed to Moore's law as the technology has increased in capacity and processing power while decreasing in size and costs. Now you can purchase your own 3D printer for as little as $300 to $5,000; simply connect it to your Wi-Fi network, and begin downloading files to create your own 3D objects. Current 3D printers offer a wide range of colors and materials, including plastics, metal, glass, and even chocolate. That's right-you can custom print your own valentine chocolates! The only barrier to 3D printing is that the software used to control the printer is still rather difficult for the average person to use, but you can expect that to change because software makers, such as Autodesk, are quickly releasing user-friendly applications. Autodesk just released 123D, a suite of free applications that enables ordinary people to design and customize objects on their PCs or even their iPads and then send them to a 3D printer. wet. 3D printers work by first creating a digital computer-aided design (CAD) file, produced with a 3D modeling program or scanned into a 3D modeling program with a 3D scanner. To get from this digital file to instructions that the 3D printer understands, software then slices the design into hundreds or thousands of horizontal layers. Typically, the 3D printer uses either a fused deposition modeling printer, which applies the tiny layers of material, or a laser sintering process by which a laser fuses the material together. Manufacturers such as 3DSystems, Afi and MakerBot produce 3D printers for just a few thousand dollars for consumers and small businesses alike. The table below represents a few of the best 3D printed objects, according to PC Magazine and Wired. Acoustic Why print a guitar? Well, a little-known fact is that the supplies of exotic guitar woods are running considerably low, so manufacturers of instruments need to start researching for alternative materials. Scott Summit, cofounder of Bespoke Innovations, says that the good news is that there is no gold standard for guitars compared to other stringed instruments such as the violin, so they can be made of anything. In addition, guitarists prefer to have their own unique sound in addition to a customized guitar face, something that will be available with a truly original, 3D-printed guitar. Bikinis The N12 is named after Nylon 12, the material in which the bikini was 3D printed by Continuum Fashion. Nylon 12 makes an ideal swimsuit material because it is innately waterproof. As well as being the first 3D printed bikini, it is also the first bikini that actually becomes more comfortable when it gets Bionic ear To construct the ear, Princeton University researchers print the polymer gel onto an approximate ear shape and implant calf cells onto the matrix. The silver nanoparticles fuse to create an antenna, which picks up radio signals before being transferred to the cochlea, which translates the sound into brain signals. Despite all of this researchers have yet to draw up plans to attach the ear to the human head. In 2010, Stratasys and Kor Ecologic teamed up to develop Urbee, the first car ever to have its entire body 3D printed by printing layers of material on top of each other until a finished product appeared. Car parts for Comedian and car nut Jay Leno had a 1907 White Steamer with a badly Jay Leno damaged feedwater heater, a part that bolts onto the cylinders. Using a NextEngine 3D scanner and Dimension 3D printer, he was able to whip up a new one in 33 hours. "It's an amazingly versatile technology," Leno said on his website. "My EcoJet supercar needed air-conditioning ducts. We used plastic parts we designed, right out of the 3D copier. We didn't have to make these scoops out of aluminum-plastic is what they use in a real car. And the finished ones look like factory production pieces." Chocolate Some people give roses, some people give 3D-printed jewelry, some people heads give their undying love. But in Japan, you can give your lover your chocolate head so they can bite into your brain as the ultimate expression of love. Clothes Dutch designer Iris van Herpen was at Fashion Week in Paris, accompanied by MIT Media Lab's Neri Oxman, to showcase a dress that was fabricated using 3D printing technology. It was printed on an Objet Connex 500 Cars Google Glasses Meat (yes, meat) multimaterial 3D printer. Most 3D printers require creations to be printed using only one type of fabric or material, but the Connex500 allows mixing of different types of material. Chinese entrepreneur Sunny Gao printed a fully functioning pair of Google Glasses at a hackathon event in Shanghai. Unfortunately, the 3D printed version of the glasses doesn't boast Wi-Fi or Bluetooth support, unlike the real thing but they are identical in every other way. U.S. start-up Modern Meadow believes it can make artificial raw meat using a 3D bioprinter, the BBC reported. Peter Thiel, one of Silicon Valley's most prominent venture capitalists, PayPal cofounder, and early Facebook investor, has just backed the company with $350,000. The team reportedly has a prototype, but it's "not ready for consumption." Easton LaChappelle, a 17-year-old high school student from Colorado, used free online resources for 3D printers to construct a fully functional prosthetic arm and hand. The high school student found inspiration from one of his past projects, which involved building a robotic hand made entirely of LEGOS when he was 14. His creation was able to open and close its fingers using two things: fishing line and servomotors. Robotic prosthetic Questions 5. Propose a plan for how a company can use 3D printing to increase sales and customer satisfaction. 6. Argue for or against the following statement: "3D printing will be more disruptive to business than the Internet