Question: CASE STUDY 1 QUESTIONS: 1.1 Identify the different main micro-operations at Hogsmeadow Garden Centre and describe the main transformed resources, transformation resources, and output. (16)

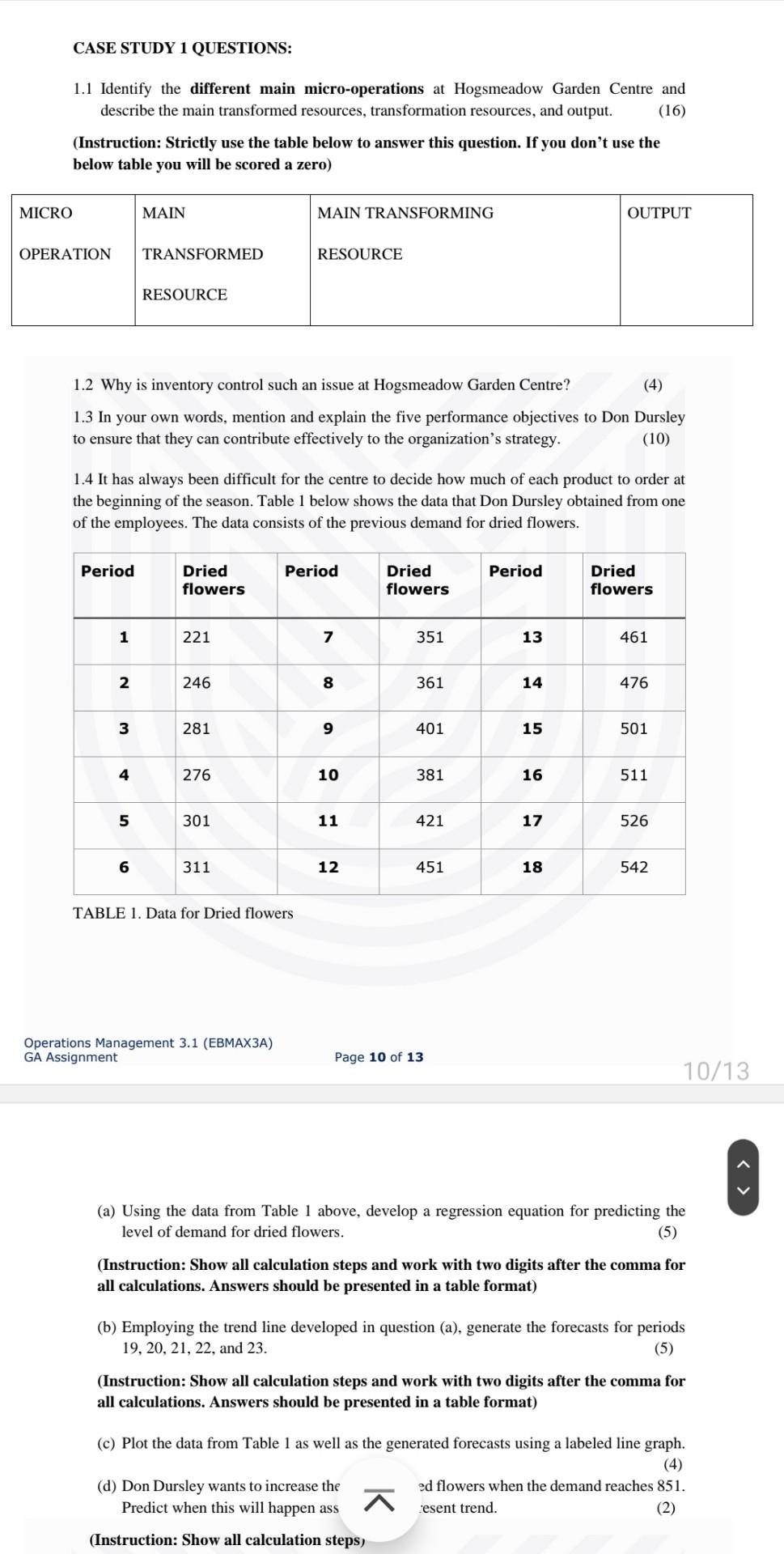

CASE STUDY 1 QUESTIONS: 1.1 Identify the different main micro-operations at Hogsmeadow Garden Centre and describe the main transformed resources, transformation resources, and output. (16) (Instruction: Strictly use the table below to answer this question. If you don't use the below table you will be scored a zero) 1.2 Why is inventory control such an issue at Hogsmeadow Garden Centre? 1.3 In your own words, mention and explain the five performance objectives to Don Dursley to ensure that they can contribute effectively to the organization's strategy. (10) 1.4 It has always been difficult for the centre to decide how much of each product to order at the beginning of the season. Table 1 below shows the data that Don Dursley obtained from one of the employees. The data consists of the previous demand for dried flowers. TABLE 1. Data for Dried flowers erations Management 3.1 (EBMAX3A) Assignment Page 10 of 13 (a) Using the data from Table 1 above, develop a regression equation for predicting the level of demand for dried flowers. (Instruction: Show all calculation steps and work with two digits after the comma for all calculations. Answers should be presented in a table format) (b) Employing the trend line developed in question (a), generate the forecasts for periods 19,20,21,22, and 23. (Instruction: Show all calculation steps and work with two digits after the comma for all calculations. Answers should be presented in a table format) (c) Plot the data from Table 1 as well as the generated forecasts using a labeled line graph. (4) (d) Don Dursley wants to increase the ed flowers when the demand reaches 851 . Predict when this will happen ass esent trend. (2) 1.5 Mention and explain one operations strategy that the manager of Honeydukes Restaurant employs. Support your answer by quoting from the case above. rations Management 3.1 (EBMAX3A) Assignment Page 11 of 13 Topics: Supply Networking, Improvement, Planning \& Control Case Study 2: Whirlpool Corporation Whirlpool Corporation Whirlpool Corporation is a leader of the $100 billion global home appliance industry. Ranked sixth in the electronics industry list of FORTUNE magazines "World's Most Admired Companies", Whirlpool Corporation is a Fortune 500 company and the world's leading manufacturer and marketer of major home appliances. Annual sales are approximately $19 billion, and there are 70,000 employees, with 69 manufacturing and technology research centers around the world. Founded in 1911, the company markets Whirlpool, Maytag, KitchenAid. Jenn-Air, Amana, Brastemp, Consul, Bauknecht and other major brand names to consumers in most countries around the world. Whirlpool manufactures appliances across all major categories. Including fabric care, cooking, refrigeration, dishwashers, countertop appliances, garage organization and water filtration. Whirlpool is committed to a brand value-creation strategy-focusing on innovation, cost productivity, product quality and consumer value. The company continues to improve its global operating platform to ensure it is the best-cost and best-quality appliance manufacturer worldwide. Its supply chain has been transformed to better deliver products to trade customers and consumers. The benefits of actions are evident through a stronger network, increased efficiencies and timely deliveries. Whirlpool Corporation is committed to building products which consumers around the world can depend upon to meet their daily needs. This commitment to quality begins in the concept stages and continues throughout the lifetime of the appliance. Globally, Whirlpool Corporation manufactures products using principles of lean manufacturing and operational excellence (OPEX) to ensure continuous improvement (CI) of processes and to produce products that meet the company's high-quality standards. At Whirlpool, there is a constant focus on seeking out new and unique ways to Improve the function, performance and sustainability of products. After acquiring the Maytag Corporation on March 31, 2006, Whirlpool Corporation became the largest home appliance maker in the world. The below information is a summary of ). Play/ read the media associated with the case. You may need to access the Inte The below information is a summary of the video clip. Play/read the media associated with the case. You may need to access the Internet and enter a URL to locate the video clips [https://www.youtube.com/watch?v=U-1FeSxcqao\&feature=youtu.be]: A merger with Maytag added another layer of complexity to Whirlpool's efforts to manage sales, orders, and cash flow. Brian Hancock, VP Supply Chain, talks about how this was achieved. Until recently, Whirlpool's strategic focus was on its products and brands. In recognition of environmental changes (customer needs in particular) attention was shifted to their supply chain and how best to manage it. The need to focus on the supply chain was also instigated by major internal and organizational changes (the merger with Maytag). Furthermore, it was ations Management 3.1 (EBMAX3A) ssignment Page 12 of 13 recognised that two issues required attention: 1) the desire for trade partners to hold lots of inventory (which impacted upon cash flows) 2) balancing number one with customers needing their products quickly. One of the goals constraining the redesign of their supply chain was to ensure a customer order could be fulfilled and delivered to the customer within 48hrs. The company set about its operations/ supply chain strategy with the aim of improving cash flow, reducing costs and providing the right service to customers. The first aspect of their strategy was the order process. Process, technology and inventory changes were made. Systems required replacement and integration with Maytag systems. Overall, there was a need to improve visibility within the supply chain. Secondly, the company rationalised facilities, reducing the number of buildings from 184 ; they eliminated 100 buildings and consolidated major warehouses into 10 regional distribution centres. This resulted in cost savings of over $60 Million. Thirdly, they optimised supply and demand, with changes to demand planning models and software and integration with upstream suppliers. CASE STUDY 2 QUESTIONS: 2.1 Describe and explain the challenges fa e company that drove the need for change. 2.2 There were drivers for change to the supply chain according to the case, Identify the drivers on March 31, 2006, Whirlpool Corporation became the largest home appliance maker in the world. The below information is a summary of the video clip. Play/read the media associated with the case. You may need to access the Internet and enter a URL to locate the video clips [https://www.youtube.com/watch?v=U-lFeSxcqao\&feature=youtu.be]: A merger with Maytag added another layer of complexity to Whirlpool's efforts to manage sales, orders, and cash flow. Brian Hancock, VP Supply Chain, talks about how this was achieved. Until recently, Whirlpool's strategic focus was on its products and brands. In recognition of environmental changes (customer needs in particular) attention was shifted to their supply chain and how best to manage it. The need to focus on the supply chain was also instigated by major internal and organizational changes (the merger with Maytag). Furthermore, it was rations Management 3.1 (EBMAX3A) Assignment Page 12 of 13 recognised that two issues required attention: 1) the desire for trade partners to hold lots of inventory (which impacted upon cash flows) 2) balancing number one with customers needing their products quickly. One of the goals constraining the redesign of their supply chain was to ensure a customer order could be fulfilled and delivered to the customer within 48hrs. The company set about its operations/ supply chain strategy with the aim of improving cash flow, reducing costs and providing the right service to customers. The first aspect of their strategy was the order process. Process, technology and inventory changes were made. Systems required replacement and integration with Maytag systems. Overall, there was a need to improve visibility within the supply chain. Secondly, the company rationalised facilities, reducing the number of buildings from 184; they eliminated 100 buildings and consolidated major warehouses into 10 regional distribution centres. This resulted in cost savings of over $60 Million. Thirdly, they optimised supply and demand, with changes to demand planning models and software and integration with upstream suppliers. CASE STUDY 2 QUESTIONS: 2.1 Describe and explain the challenges faced by the company that drove the need for change. (10) 2.2 There were drivers for change to the supply chain according to the case, Identify the drivers for change and explain each driver in detail. 2.3 Comment on how Whirlpool could efficiently manage inventory by using the following approaches: (10) (a) Utilize Just-In-Time (JIT) Inventory Management, (b) Use technology to improve inventory accuracy, (c) Collaborate with suppliers, (d) Implement a Vendor-Managed Inventory (VMI) System, (e) Implement an ABC Inventory System, CASE STUDY 1 QUESTIONS: 1.1 Identify the different main micro-operations at Hogsmeadow Garden Centre and describe the main transformed resources, transformation resources, and output. (16) (Instruction: Strictly use the table below to answer this question. If you don't use the below table you will be scored a zero) 1.2 Why is inventory control such an issue at Hogsmeadow Garden Centre? 1.3 In your own words, mention and explain the five performance objectives to Don Dursley to ensure that they can contribute effectively to the organization's strategy. (10) 1.4 It has always been difficult for the centre to decide how much of each product to order at the beginning of the season. Table 1 below shows the data that Don Dursley obtained from one of the employees. The data consists of the previous demand for dried flowers. TABLE 1. Data for Dried flowers erations Management 3.1 (EBMAX3A) Assignment Page 10 of 13 (a) Using the data from Table 1 above, develop a regression equation for predicting the level of demand for dried flowers. (Instruction: Show all calculation steps and work with two digits after the comma for all calculations. Answers should be presented in a table format) (b) Employing the trend line developed in question (a), generate the forecasts for periods 19,20,21,22, and 23. (Instruction: Show all calculation steps and work with two digits after the comma for all calculations. Answers should be presented in a table format) (c) Plot the data from Table 1 as well as the generated forecasts using a labeled line graph. (4) (d) Don Dursley wants to increase the ed flowers when the demand reaches 851 . Predict when this will happen ass esent trend. (2) 1.5 Mention and explain one operations strategy that the manager of Honeydukes Restaurant employs. Support your answer by quoting from the case above. rations Management 3.1 (EBMAX3A) Assignment Page 11 of 13 Topics: Supply Networking, Improvement, Planning \& Control Case Study 2: Whirlpool Corporation Whirlpool Corporation Whirlpool Corporation is a leader of the $100 billion global home appliance industry. Ranked sixth in the electronics industry list of FORTUNE magazines "World's Most Admired Companies", Whirlpool Corporation is a Fortune 500 company and the world's leading manufacturer and marketer of major home appliances. Annual sales are approximately $19 billion, and there are 70,000 employees, with 69 manufacturing and technology research centers around the world. Founded in 1911, the company markets Whirlpool, Maytag, KitchenAid. Jenn-Air, Amana, Brastemp, Consul, Bauknecht and other major brand names to consumers in most countries around the world. Whirlpool manufactures appliances across all major categories. Including fabric care, cooking, refrigeration, dishwashers, countertop appliances, garage organization and water filtration. Whirlpool is committed to a brand value-creation strategy-focusing on innovation, cost productivity, product quality and consumer value. The company continues to improve its global operating platform to ensure it is the best-cost and best-quality appliance manufacturer worldwide. Its supply chain has been transformed to better deliver products to trade customers and consumers. The benefits of actions are evident through a stronger network, increased efficiencies and timely deliveries. Whirlpool Corporation is committed to building products which consumers around the world can depend upon to meet their daily needs. This commitment to quality begins in the concept stages and continues throughout the lifetime of the appliance. Globally, Whirlpool Corporation manufactures products using principles of lean manufacturing and operational excellence (OPEX) to ensure continuous improvement (CI) of processes and to produce products that meet the company's high-quality standards. At Whirlpool, there is a constant focus on seeking out new and unique ways to Improve the function, performance and sustainability of products. After acquiring the Maytag Corporation on March 31, 2006, Whirlpool Corporation became the largest home appliance maker in the world. The below information is a summary of ). Play/ read the media associated with the case. You may need to access the Inte The below information is a summary of the video clip. Play/read the media associated with the case. You may need to access the Internet and enter a URL to locate the video clips [https://www.youtube.com/watch?v=U-1FeSxcqao\&feature=youtu.be]: A merger with Maytag added another layer of complexity to Whirlpool's efforts to manage sales, orders, and cash flow. Brian Hancock, VP Supply Chain, talks about how this was achieved. Until recently, Whirlpool's strategic focus was on its products and brands. In recognition of environmental changes (customer needs in particular) attention was shifted to their supply chain and how best to manage it. The need to focus on the supply chain was also instigated by major internal and organizational changes (the merger with Maytag). Furthermore, it was ations Management 3.1 (EBMAX3A) ssignment Page 12 of 13 recognised that two issues required attention: 1) the desire for trade partners to hold lots of inventory (which impacted upon cash flows) 2) balancing number one with customers needing their products quickly. One of the goals constraining the redesign of their supply chain was to ensure a customer order could be fulfilled and delivered to the customer within 48hrs. The company set about its operations/ supply chain strategy with the aim of improving cash flow, reducing costs and providing the right service to customers. The first aspect of their strategy was the order process. Process, technology and inventory changes were made. Systems required replacement and integration with Maytag systems. Overall, there was a need to improve visibility within the supply chain. Secondly, the company rationalised facilities, reducing the number of buildings from 184 ; they eliminated 100 buildings and consolidated major warehouses into 10 regional distribution centres. This resulted in cost savings of over $60 Million. Thirdly, they optimised supply and demand, with changes to demand planning models and software and integration with upstream suppliers. CASE STUDY 2 QUESTIONS: 2.1 Describe and explain the challenges fa e company that drove the need for change. 2.2 There were drivers for change to the supply chain according to the case, Identify the drivers on March 31, 2006, Whirlpool Corporation became the largest home appliance maker in the world. The below information is a summary of the video clip. Play/read the media associated with the case. You may need to access the Internet and enter a URL to locate the video clips [https://www.youtube.com/watch?v=U-lFeSxcqao\&feature=youtu.be]: A merger with Maytag added another layer of complexity to Whirlpool's efforts to manage sales, orders, and cash flow. Brian Hancock, VP Supply Chain, talks about how this was achieved. Until recently, Whirlpool's strategic focus was on its products and brands. In recognition of environmental changes (customer needs in particular) attention was shifted to their supply chain and how best to manage it. The need to focus on the supply chain was also instigated by major internal and organizational changes (the merger with Maytag). Furthermore, it was rations Management 3.1 (EBMAX3A) Assignment Page 12 of 13 recognised that two issues required attention: 1) the desire for trade partners to hold lots of inventory (which impacted upon cash flows) 2) balancing number one with customers needing their products quickly. One of the goals constraining the redesign of their supply chain was to ensure a customer order could be fulfilled and delivered to the customer within 48hrs. The company set about its operations/ supply chain strategy with the aim of improving cash flow, reducing costs and providing the right service to customers. The first aspect of their strategy was the order process. Process, technology and inventory changes were made. Systems required replacement and integration with Maytag systems. Overall, there was a need to improve visibility within the supply chain. Secondly, the company rationalised facilities, reducing the number of buildings from 184; they eliminated 100 buildings and consolidated major warehouses into 10 regional distribution centres. This resulted in cost savings of over $60 Million. Thirdly, they optimised supply and demand, with changes to demand planning models and software and integration with upstream suppliers. CASE STUDY 2 QUESTIONS: 2.1 Describe and explain the challenges faced by the company that drove the need for change. (10) 2.2 There were drivers for change to the supply chain according to the case, Identify the drivers for change and explain each driver in detail. 2.3 Comment on how Whirlpool could efficiently manage inventory by using the following approaches: (10) (a) Utilize Just-In-Time (JIT) Inventory Management, (b) Use technology to improve inventory accuracy, (c) Collaborate with suppliers, (d) Implement a Vendor-Managed Inventory (VMI) System, (e) Implement an ABC Inventory System

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts