Question: Case Study #1: Using Material Pull to Improve a Pharmacy Process The Background: Medications and IV Fluids were being replenished using visual inspections, daily inventory

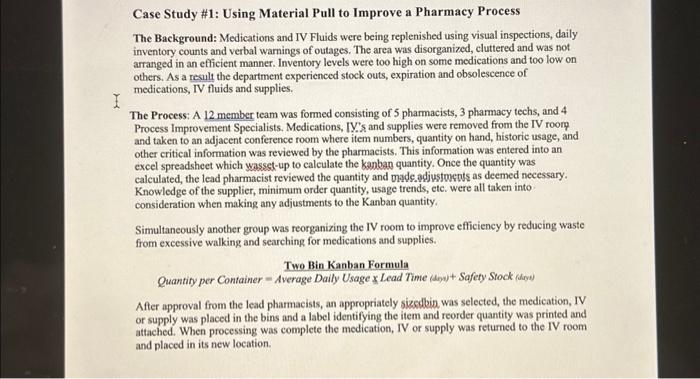

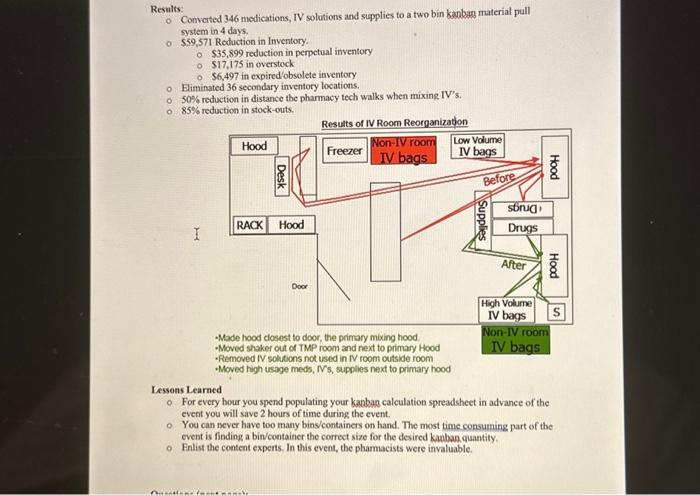

Case Study \#1: Using Material Pull to Improve a Pharmacy Process The Background: Medications and IV Fluids were being replenished using visual inspections, daily inventory counts and verbal warnings of outages. The area was disorganized, cluttered and was not arranged in an efficient manner. Inventory levels were too high on some medications and too low on others. As a result the department experienced stock outs, expiration and obsolescence of medications, IV fluids and supplies. The Process: A 12 member team was formed consisting of 5 pharmacists, 3 pharmacy techs, and 4 Process Improvement Specialists. Medications, IY.s and supplies were removed from the IV room and taken to an adjacent conference room where item numbers, quantity on hand, historic usage, and other critical information was reviewed by the pharmacists. This information was entered into an excel spreadsheet which wasset-up to calculate the kanban quantity. Once the quantity was calculated, the lead pharmacist reviewed the quantity and oade.adjustowents as deemed necessary. Knowledge of the supplier, minimum order quantity, usage trends, etc. were all taken into consideration when making any adjustments to the Kanban quantity. Simultaneously another group was reorganizing the IV room to improve efficiency by reducing waste from excessive walking and searching for medications and supplies. Two Bin Kanban Formula Quantity per Container = Average Daily Usage x Lead Time (doy) + Safety Stock (deye) After approval from the lead pharmacists, an appropriately sizedbia was selected, the medication, IV or supply was placed in the bins and a label identifying the item and reorder quantity was printed and attached. When processing was complete the medication, IV or supply was returned to the IV room and placed in its new location. Results: - Converted 346 medications, IV solutions and supplies to a two bin kanbsu material pull system in 4 days. - $59,571 Reduction in Inventory. - $35,899 reduction in perpetual inventory - $17,175 in overstock - $6,497 in expired/obsolete inventory Eliminated 36 secondary inventory locations. 50% reduction in distance the pharmacy tech walks when mixing IV's. 85% reduction in stock-outs. -Moved high usage meds, IVs, supplies next to primary hood Lessons Learned - For every hour you spend populating your kanbas calculation spreadsheet in advance of the event you will save 2 hours of time during the event. - You can never have too many bins/containers on hand. The most time consuming part of the event is finding a bin/container the correct sixe for the desired kanban quantity. - Fnlist the content experts. In this event, the phamacists were invaluable. 1. Explain how the solution implemented in this case study reduced the space requirements ( 10 points). 2. Explain the Material Handling Equation and how can be applied to this case study (20 points)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts