Question: Case Study 2 - Cut and Path Vectors for Reliability Assessment of Manufacturing Line Background A materials manufacturer produces a type of compound sensitive to

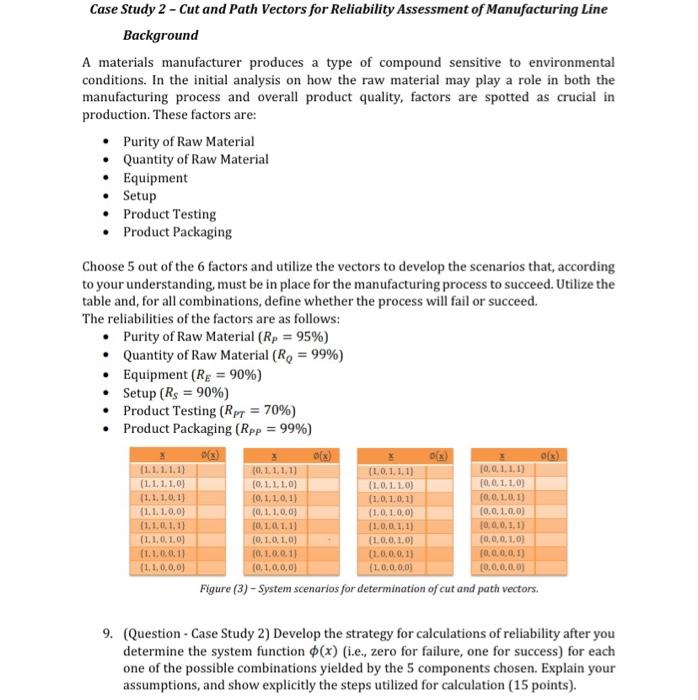

Case Study 2 - Cut and Path Vectors for Reliability Assessment of Manufacturing Line Background A materials manufacturer produces a type of compound sensitive to environmental conditions. In the initial analysis on how the raw material may play a role in both the manufacturing process and overall product quality, factors are spotted as crucial in production. These factors are: Purity of Raw Material Quantity of Raw Material Equipment Setup Product Testing Product Packaging Choose 5 out of the 6 factors and utilize the vectors to develop the scenarios that according to your understanding, must be in place for the manufacturing process to succeed. Utilize the table and for all combinations, define whether the process will fail or succeed. The reliabilities of the factors are as follows: Purity of Raw Material (Rp = 95%) Quantity of Raw Material (RQ = 99%) Equipment (Rp = 90%) Setup (Rs = 90%) Product Testing (Rpt = 70%) Product Packaging (Rpp = 99%) 0(s) 0() (1.1.1.1.1) (0.1.1,1,1) (1.0.1.1.11 10.0, 1.1.1) (1.1,1.1,0) (0.1.1, 1.0 (LOLLO) [0,0,1,1,0) 11.1.1.0.1) [0,1,1,0,1) (1,0,1,0,1) 0.0.1,0.1) 11.1.1.0.0) (0,1.1.0.0) (1,0,1,0,0) (0.0,1,0,0) (1.1.0.1.1) 10.1.0.1.1) 11.0.0.1.11 (0,0,0,1,1) (1,1,0,1,0) 10.1.0.1,0) (1,0,0,1,0) [0,0,0,1,0) (1.1.0.0.11 10.1.00.11 (1,0,0,0.1) [0,0,0,0,1) (1,1,0,0,0) 10.1,0,0,0) [1.0.0.0,01 (0,0,0,0,01 Figure (3) - System scenarios for determination of cut and path vectors. 9. (Question - Case Study 2) Develop the strategy for calculations of reliability after you determine the system function (x) (i.e., zero for failure, one for success) for each one of the possible combinations yielded by the 5 components chosen. Explain your assumptions, and show explicitly the steps utilized for calculation (15 points). Case Study 2 - Cut and Path Vectors for Reliability Assessment of Manufacturing Line Background A materials manufacturer produces a type of compound sensitive to environmental conditions. In the initial analysis on how the raw material may play a role in both the manufacturing process and overall product quality, factors are spotted as crucial in production. These factors are: Purity of Raw Material Quantity of Raw Material Equipment Setup Product Testing Product Packaging Choose 5 out of the 6 factors and utilize the vectors to develop the scenarios that according to your understanding, must be in place for the manufacturing process to succeed. Utilize the table and for all combinations, define whether the process will fail or succeed. The reliabilities of the factors are as follows: Purity of Raw Material (Rp = 95%) Quantity of Raw Material (RQ = 99%) Equipment (Rp = 90%) Setup (Rs = 90%) Product Testing (Rpt = 70%) Product Packaging (Rpp = 99%) 0(s) 0() (1.1.1.1.1) (0.1.1,1,1) (1.0.1.1.11 10.0, 1.1.1) (1.1,1.1,0) (0.1.1, 1.0 (LOLLO) [0,0,1,1,0) 11.1.1.0.1) [0,1,1,0,1) (1,0,1,0,1) 0.0.1,0.1) 11.1.1.0.0) (0,1.1.0.0) (1,0,1,0,0) (0.0,1,0,0) (1.1.0.1.1) 10.1.0.1.1) 11.0.0.1.11 (0,0,0,1,1) (1,1,0,1,0) 10.1.0.1,0) (1,0,0,1,0) [0,0,0,1,0) (1.1.0.0.11 10.1.00.11 (1,0,0,0.1) [0,0,0,0,1) (1,1,0,0,0) 10.1,0,0,0) [1.0.0.0,01 (0,0,0,0,01 Figure (3) - System scenarios for determination of cut and path vectors. 9. (Question - Case Study 2) Develop the strategy for calculations of reliability after you determine the system function (x) (i.e., zero for failure, one for success) for each one of the possible combinations yielded by the 5 components chosen. Explain your assumptions, and show explicitly the steps utilized for calculation (15 points)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts