Question: Case Study 2: Notex Manufacturing (10 marks) Notex Manufacturing makes various batteries used in mobile devices. The company has a major customer so batteries are

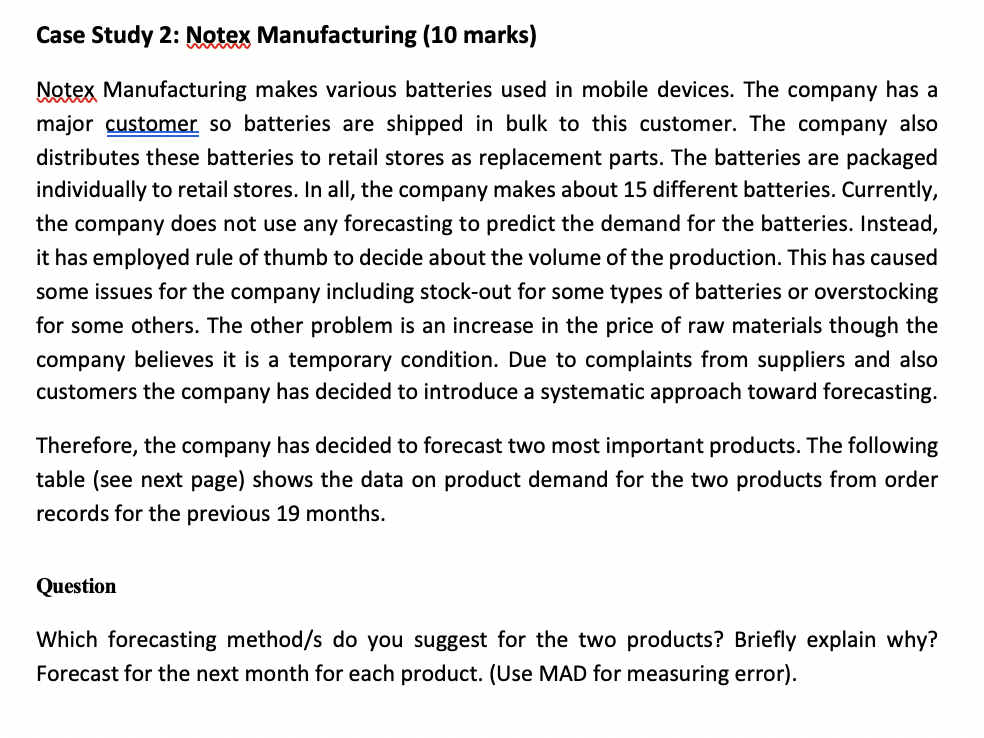

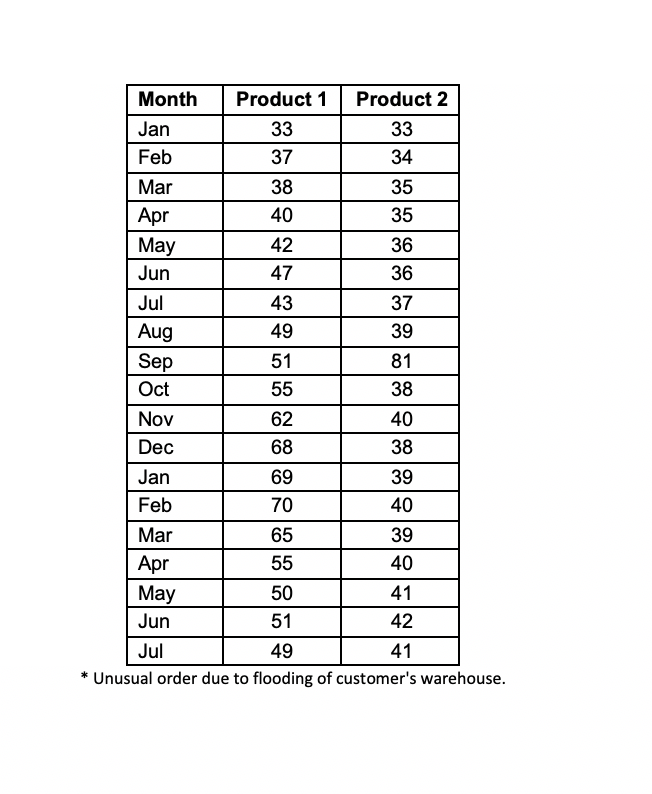

Case Study 2: Notex Manufacturing (10 marks) Notex Manufacturing makes various batteries used in mobile devices. The company has a major customer so batteries are shipped in bulk to this customer. The company also distributes these batteries to retail stores as replacement parts. The batteries are packaged individually to retail stores. In all, the company makes about 15 different batteries. Currently, the company does not use any forecasting to predict the demand for the batteries. Instead, it has employed rule of thumb to decide about the volume of the production. This has caused some issues for the company including stock-out for some types of batteries or overstocking for some others. The other problem is an increase in the price of raw materials though the company believes it is a temporary condition. Due to complaints from suppliers and also customers the company has decided to introduce a systematic approach toward forecasting. Therefore, the company has decided to forecast two most important products. The following table (see next page) shows the data on product demand for the two products from order records for the previous 19 months. Question Which forecasting method/s do you suggest for the two products? Briefly explain why? Forecast for the next month for each product. (Use MAD for measuring error). 33 33 34 38 42 47 36 51 81 Month Product 1 | Product 2 Jan Feb 37 Mar 35 Apr 40 35 May 36 Jun Jul 43 37 Aug 49 39 Sep Oct 55 38 Nov 62 40 Dec 68 38 Jan 69 39 Feb 70 40 Mar 65 39 Apr 55 May 50 41 Jun 42 Jul 49 * Unusual order due to flooding of customer's warehouse. 40 51 41 Case Study 2: Notex Manufacturing (10 marks) Notex Manufacturing makes various batteries used in mobile devices. The company has a major customer so batteries are shipped in bulk to this customer. The company also distributes these batteries to retail stores as replacement parts. The batteries are packaged individually to retail stores. In all, the company makes about 15 different batteries. Currently, the company does not use any forecasting to predict the demand for the batteries. Instead, it has employed rule of thumb to decide about the volume of the production. This has caused some issues for the company including stock-out for some types of batteries or overstocking for some others. The other problem is an increase in the price of raw materials though the company believes it is a temporary condition. Due to complaints from suppliers and also customers the company has decided to introduce a systematic approach toward forecasting. Therefore, the company has decided to forecast two most important products. The following table (see next page) shows the data on product demand for the two products from order records for the previous 19 months. Question Which forecasting method/s do you suggest for the two products? Briefly explain why? Forecast for the next month for each product. (Use MAD for measuring error). 33 33 34 38 42 47 36 51 81 Month Product 1 | Product 2 Jan Feb 37 Mar 35 Apr 40 35 May 36 Jun Jul 43 37 Aug 49 39 Sep Oct 55 38 Nov 62 40 Dec 68 38 Jan 69 39 Feb 70 40 Mar 65 39 Apr 55 May 50 41 Jun 42 Jul 49 * Unusual order due to flooding of customer's warehouse. 40 51 41

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts