Question: CASE STUDY 8S.1: SALES AND OPERATIONS PLANNING BY CONSIDERING ALTERNATIVE DEMAND SCENARIOS-USE OF LINEAR PROGRAMMING TechniKey is a company specializing in the manufacturing of water

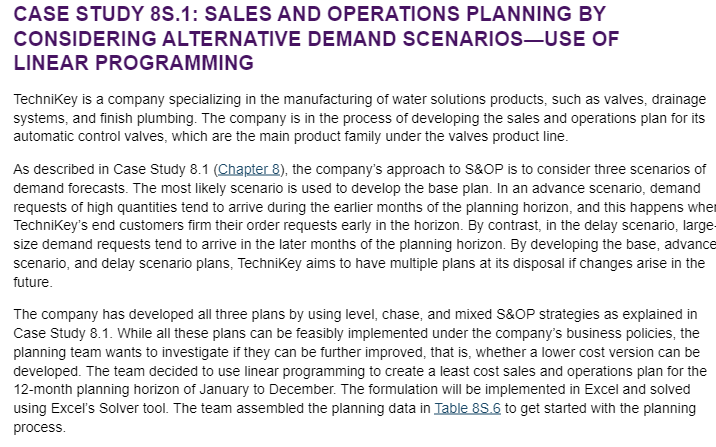

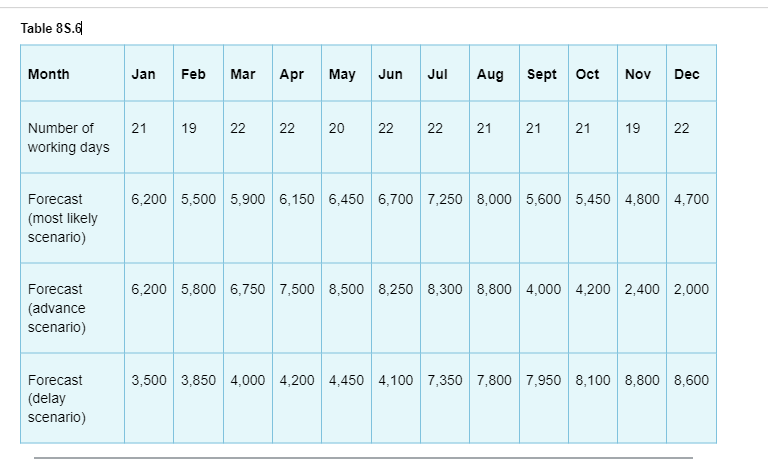

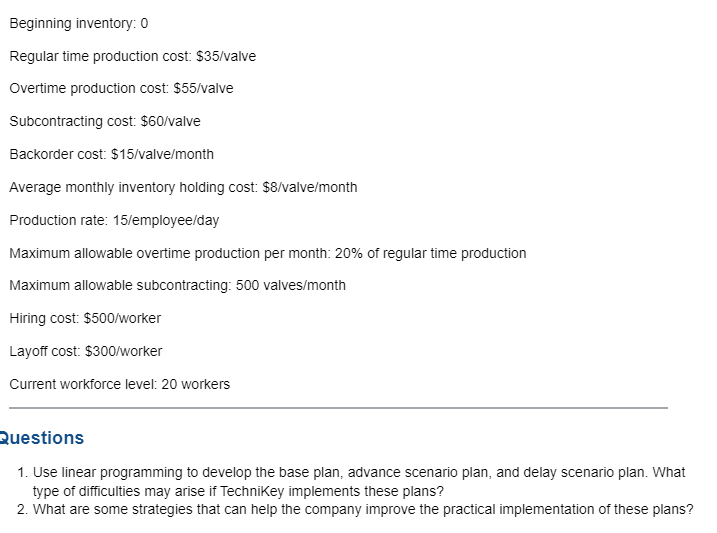

CASE STUDY 8S.1: SALES AND OPERATIONS PLANNING BY CONSIDERING ALTERNATIVE DEMAND SCENARIOS-USE OF LINEAR PROGRAMMING TechniKey is a company specializing in the manufacturing of water solutions products, such as valves, drainage systems, and finish plumbing. The company is in the process of developing the sales and operations plan for its automatic control valves, which are the main product family under the valves product line. As described in Case Study 8.1 (Chapter 8), the company's approach to S\&OP is to consider three scenarios of demand forecasts. The most likely scenario is used to develop the base plan. In an advance scenario, demand requests of high quantities tend to arrive during the earlier months of the planning horizon, and this happens whe TechniKey's end customers firm their order requests early in the horizon. By contrast, in the delay scenario, large size demand requests tend to arrive in the later months of the planning horizon. By developing the base, advanc scenario, and delay scenario plans, TechniKey aims to have multiple plans at its disposal if changes arise in the future. The company has developed all three plans by using level, chase, and mixed S\&OP strategies as explained in Case Study 8.1. While all these plans can be feasibly implemented under the company's business policies, the planning team wants to investigate if they can be further improved, that is, whether a lower cost version can be developed. The team decided to use linear programming to create a least cost sales and operations plan for the 12-month planning horizon of January to December. The formulation will be implemented in Excel and solved using Excel's Solver tool. The team assembled the planning data in Table 8$,6 to get started with the planning process. Table 8S.6 Beginning inventory: 0 Regular time production cost: $35/ valve Overtime production cost: $55/ valve Subcontracting cost: $60/ valve Backorder cost: \$15/valve/month Average monthly inventory holding cost: $8/valve/ month Production rate: 15/employee/day Maximum allowable overtime production per month: 20% of regular time production Maximum allowable subcontracting: 500 valves/month Hiring cost: $500/ worker Layoff cost: $300/ worker Current workforce level: 20 workers Questions 1. Use linear programming to develop the base plan, advance scenario plan, and delay scenario plan. What type of difficulties may arise if TechniKey implements these plans? 2. What are some strategies that can help the company improve the practical implementation of these plans

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts