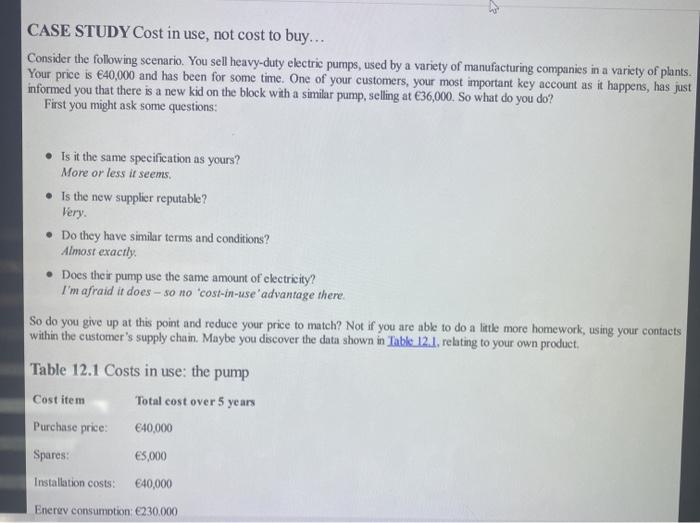

CASE STUDY Cost in use, not cost to buy... Consider the following scenario. You sell heavy-duty electric pumps, used by a variety of manufacturing companies in a variety of plants. Your price is 40,000 and has been for some time. One of your customers, your most important key account as it happens, has just informed you that there is a new kid on the block with a similar pump, selling at 36,000. So what do you do? First you might ask some questions: Is it the same specification as yours? More or less it seems Is the new supplier reputable? Very. Do they have similar terms and conditions ? Almost exactly Does their pump use the same amount of electricity? I'm afraid it does - 80 no cost-in-use advantage there So do you give up at this point and reduce your price to match? Not if you are able to do a little more homework, using your contacts within the customer's supply chain. Maybe you discover the data shown in Table 12.1. relating to your own product, Table 12.1 Costs in use: the pump Total cost over 5 years Purchase price: 40,000 Cost item Spares: 5,000 Installation costs: 40,000 Energy consumption: 230.000 KURID PUUV Maintenance: 35,000 Disposal 4,000 Total costs in use 354,000 The most significant item by far is the energy consumption - as much as 65 per cent of the total costs over a five-year period. But didn't we discover that the competitor's product had the same energy consumption? We did, but that is to limit yourself to the realm of a salesperson. What if this is a key account, and you are the KA manager? Wouldn't it be worth investing time with your own R&D and manufacturing people to see whether it might be possible to develop a new pump with, let's say, a 10 per cent advantage in energy consumption over the old? They tell you that it is possible, but at a cost. You do some sums, It will cost us more, but if I can sell it for 44,000 then that will see a positive return on the investment in just over two But wasn't the competitor down at 36,000-how on earth can you justify raising your price to 44,000? Because a saving of 10 per cent on energy consumption is of far greater value to the customer than the saving of 4,000 (or even 8,000) per pump. That's cost in use talking Sure there are a dozen things that could wreck such a strategy, here are just a few of them: years You have no authority to have this kind of conversation with your own people: - You're still a sales professional in that case, not a Ka manager: Your boss demands a retum on customer investments within a year: - Your company isnt practising KAM yet. The buyer only buys pumps, not the energy - so why should they care? -If they're an SCM-minded buyer they will, or should... But if they don't find the people who de buy energy Case Study - Cost in use, not cost to buy 1. Review the case study on pages 137 - 138 of our textbook. If your energy consumption savings over 5 years equals a 10 percent saving, how much do you save in a euro amount? 2. Explain the difference between "cost in use" and "cost to buy". How could this help you develop a value proposition? 3. Based on this saving, what other strategies could you employ to keep this customer happy other than the ones supplied in this case study. List three other strategies