Question: CASE STUDY Designing the Distribution Network for Michael's Hardware Ellen Lin, vice president of supply chain at Michael's improve its distribution costs, especially given the

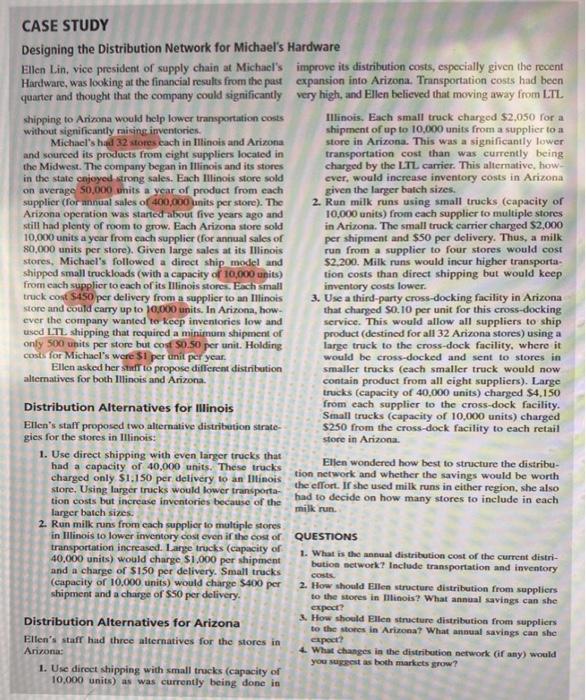

CASE STUDY Designing the Distribution Network for Michael's Hardware Ellen Lin, vice president of supply chain at Michael's improve its distribution costs, especially given the recent Hardware, was looking at the financial results from the past expansion into Arizona. Transportation costs had been quarter and thought that the company could significantly very high, and Ellen believed that moving away from LTL shipping to Arizona would help lower transportation costs Illinois. Each small truck charged $2,050 for a without significantly raising inventories shipment of up to 10,000 units from a supplier to a Michael's had 32 stores each in Illinois and Arizona store in Arizona. This was a significantly lower and sourced its products from eight suppliers located in transportation cost than was currently being the Midwest. The company began in Illinois and its stores charged by the LTL carrier. This alternative, how in the state enjoyed strong sales. Each Illinois store sold cver, would increase inventory costs in Arizona on average 50,000 units a year of product from each given the larger batch sizes. supplier (for annual sales of 400,000 units per store). The 2. Run milk runs using small trucks (capacity of Arizona operation was started about five years ago and 10,000 units) from each supplier to multiple stores still had plenty of room to grow. Each Arizona store sold in Arizona. The small truck carrier charged $2,000 10,000 units a year from each supplier (for annual sales of per shipment and $50 per delivery. Thus, a milk 80,000 units per store). Given large sales at its Illinois run from a supplier to four stores would cost stores, Michael's followed a direct ship model and $2,200. Milk runs would incur higher transporta shipped small truckloads (with a capacity of 10,000 units) tion costs than direct shipping but would keep from each supplier to each of its Illinois stores. Each small inventory costs lower truck cost $450 per delivery from a supplier to an Illinois 3. Use a third-party cross-docking facility in Arizona store and could carry up to 10,000 units. In Arizona, how that charged SO. 10 per unit for this cross-docking ever the company wanted to keep inventories low and service. This would allow all suppliers to ship used LTL shipping that required a minimum shipment of product (destined for all 32 Arizona stores) using a only 500 units per store but cost $0.50 per unit. Holding large truck to the cross-dock facility, where it costs for Michael's were $1 per unit per year. would be cross-docked and sent to stores in Ellen asked her staf to propose different distribution smaller trucks (each smaller truck would now alternatives for both Illinois and Arizona contain product from all cight suppliers). Large trucks (capacity of 40,000 units) charged $4.150 Distribution Alternatives for Illinois from each supplier to the cross-dock facility. Small trucks (capacity of 10,000 units) charged Ellen's staff proposed two alternative distribution strate- $250 from the cross-dock facility to each retail gies the stores in Illinois: store in Arizona 1. Use direct shipping with even larger trucks that had a capacity of 40,000 units. These trucks Ellen wondered how best to structure the distribu- charged only $1.150 per delivery to an Illinois tion network and whether the savings would be worth store. Using larger trucks would lower transport the effort. If she used milk runs in either region, she also tion costs but increase inventories because of the had to decide on how many stores to include in each larger batch sizes. milk run. 2. Run milk runs from each supplier to multiple stores in Illinois to lower inventory cost even if the cost of QUESTIONS transportation increased. Large trucks (capacity of 1. What is the annual distribution cost of the current distri 40.000 units) would charge $1,000 per shipment bution network? Include transportation and inventory and a charge of $150 per delivery. Small trucks (capacity of 10,000 units) would charge $400 per 2. How should Ellen structure distribution from suppliers shipment and a charge of SS0 per delivery. to the stores in Tilinois? What annual savings can she expect? Distribution Alternatives for Arizona 3. How should Ellen strature distribution from suppliers to the stores in Arizona? What annual savings can she Ellen's staff had three alternatives for the stores in expect? Arizona: 4. What changes in the distribution network of any) would you suggest as both markets grow? 1. Use direct shipping with small trucks (capacity of 10,000 units) as was currently being done in co