Question: Case Study: Heinkel - Fishbein, Inc. Heinkel - Fishbein is a large importer and distributor of robotic toys. The toys are stored in the warehouse

Case Study: HeinkelFishbein, Inc.

HeinkelFishbein is a large importer and distributor of robotic toys. The toys are stored in the

warehouse and are shipped to a several large retail chains at a standard price.. There is almost no possibility

in the near future of changing the prices at which HeinkelFishbein supplies the retail stores. Thus there is

a need to increase profits by managing total costs.

Considering one toy, identified as SKU the process consists of receiving the boxes as shipped

by the manufacturer, and storing in the warehouse to be divided and shipped to the stores as per shipment

schedule. The cost factors are described as follows. The suppliers have a discount schedule, and the prices

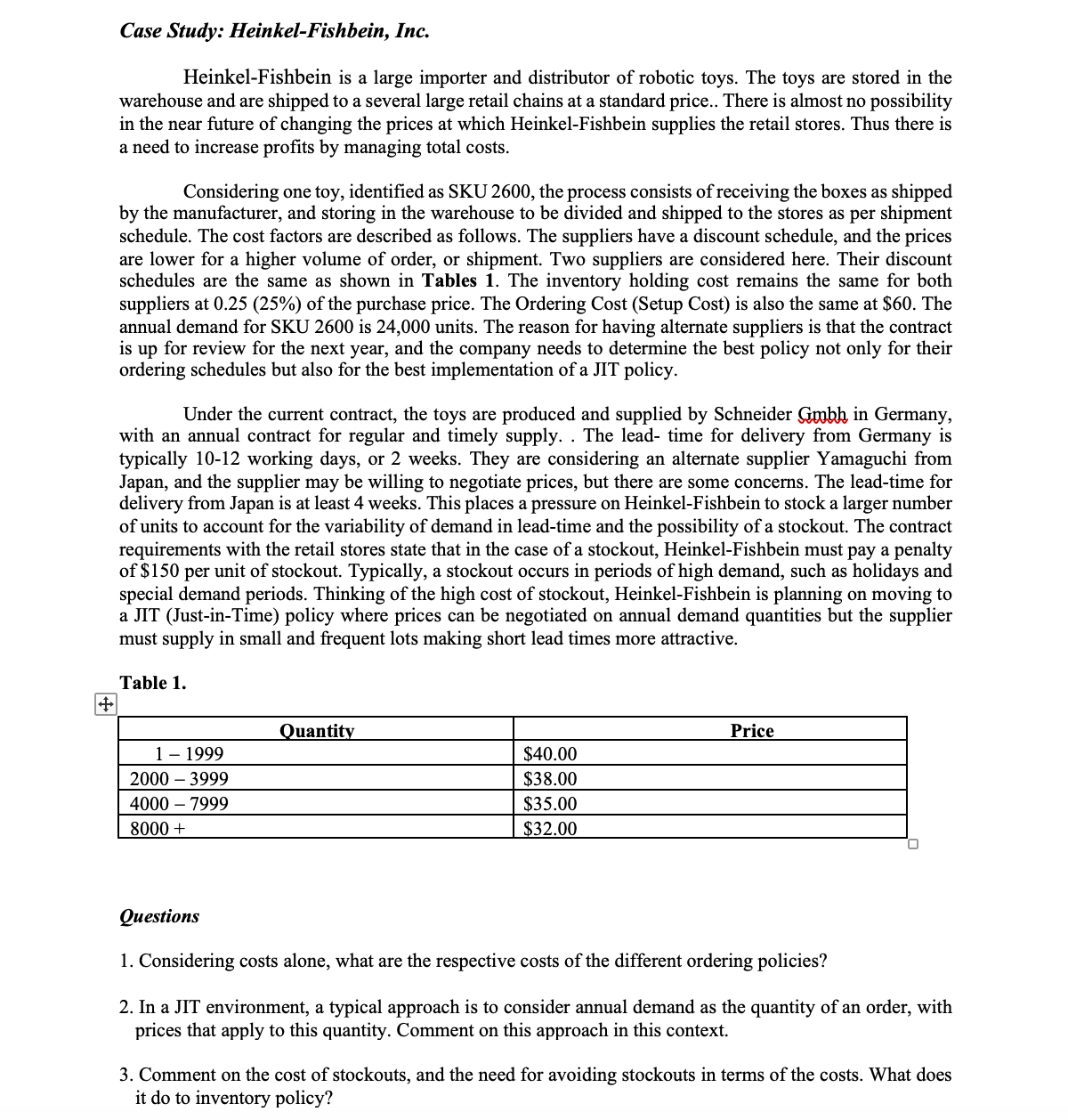

are lower for a higher volume of order, or shipment. Two suppliers are considered here. Their discount

schedules are the same as shown in Tables The inventory holding cost remains the same for both

suppliers at of the purchase price. The Ordering Cost Setup Cost is also the same at $ The

annual demand for SKU is units. The reason for having alternate suppliers is that the contract

is up for review for the next year, and the company needs to determine the best policy not only for their

ordering schedules but also for the best implementation of a JIT policy.

Under the current contract, the toys are produced and supplied by Schneider Gmbh in Germany,

with an annual contract for regular and timely supply. The lead time for delivery from Germany is

typically working days, or weeks. They are considering an alternate supplier Yamaguchi from

Japan, and the supplier may be willing to negotiate prices, but there are some concerns. The leadtime for

delivery from Japan is at least weeks. This places a pressure on HeinkelFishbein to stock a larger number

of units to account for the variability of demand in leadtime and the possibility of a stockout. The contract

requirements with the retail stores state that in the case of a stockout, HeinkelFishbein must pay a penalty

of $ per unit of stockout. Typically, a stockout occurs in periods of high demand, such as holidays and

special demand periods. Thinking of the high cost of stockout, HeinkelFishbein is planning on moving to

a JIT JustinTime policy where prices can be negotiated on annual demand quantities but the supplier

must supply in small and frequent lots making short lead times more attractive

Answer question with data tables in an excel spreadsheet

Considering costs alone, what are the respective costs of the differ

A quick reading of the problem indicates that the main question is about inventory and inventory management. Inventory Management is Chapter in the text book. If it has been a while since you read that chapter, it may be a good idea to go back and glance at the chapter again. Specifically the question is about the optimal policy for ordering and inventory, which translates into calculating the optimal order quantities. The book describes three inventory models, respectively Economic Order Quantity, Economic Production Quantity, and Quantity Discount. When you look at the given data and the price discounts that go with different order volumes, the problem has a clear fit with the Quantity Discount model and no other. Refer again to the book. The Quantity Discount model requires you to calculate the total cost for each order policy using the formula below:

TC PD QH DQS

The Purchase Price P varies according to the order quantity Q and Holding Cost H is expressed as a fraction of the Purchase Price.

The first step is to calculate the Order Quantity Q for each discount level, or each purchase price bracket. This is done by using the basic EOQ formula refer to book Please do not be confused by the word infeasible in the book. All that it means is that you cannot get the discount if the order quantity is less than the threshold for the discount. You must bump the Order Quantity up to the minimum level required to get the discounted price, and then calculate total cost using this Order Quantity. In the end, you will have a Total Cost for each discount price for each supplier. The best lowest Total Cost will be the best policy to use.ent ordering policies?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock