Question: Case Study: Myer wine racking and cellar company, revisted. Please answer questions 1-4 with explanation please 362 Chapter 11 CASE STUDY: MYER WINE RACKING AND

Case Study: Myer wine racking and cellar company, revisted.

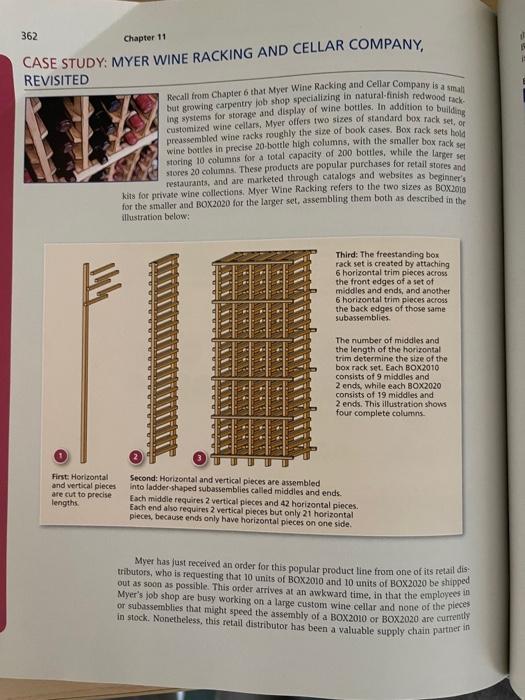

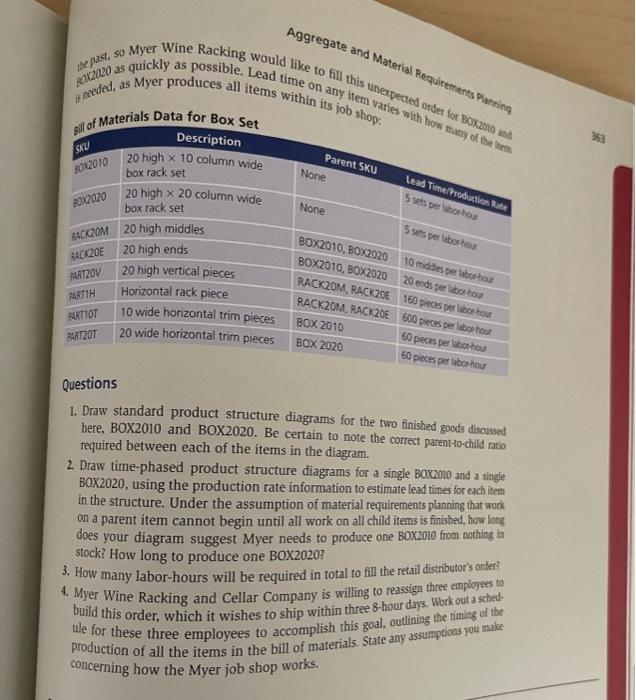

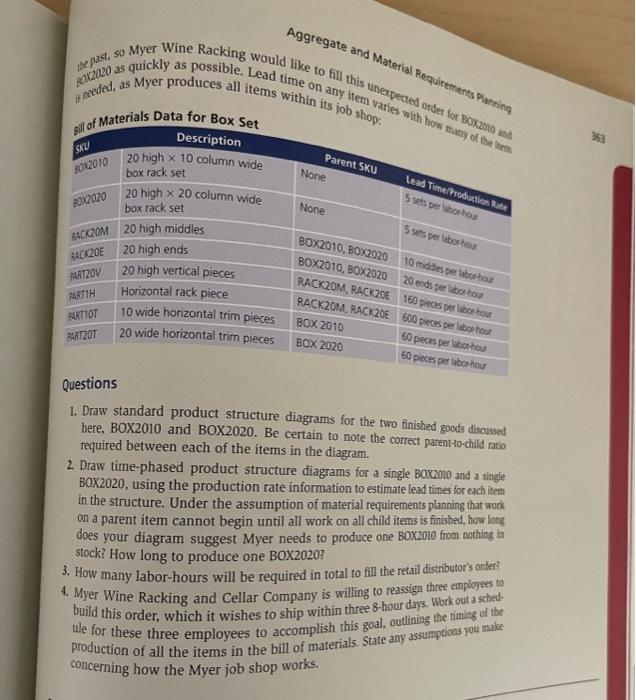

362 Chapter 11 CASE STUDY: MYER WINE RACKING AND CELLAR COMPANY, REVISITED Recall from Chapter 6 that Myer Wine Racking and Cellar Company is a small but growing carpentry fob shop specializing in natural-finish redwood tack Ing systems for storage and display of wine bottles. In addition to building, customized wine cellars, Myer offers two sizes of standard box rack set, or preassembled wine racks roughly the size of book cases. Box rack sets how storing 10 columns for a total capacity of 200 bottles, while the larger ser wine bottles in precise 20 bottle high columns with the smaller box rack stores 20 columns. These products are popular purchases for retail stores and restaurants, and are marketed through catalogs and websites as beginner's kits for private wine collections. Myer Wine Racking refers to the two sizes as BOX 2010 for the smaller and BOX2020 for the larger set, assembling them both as described in the illustration below: Third: The freestanding box rack set is created by attaching 6 horizontal trim pleces across the front edges of a set of middles and ends, and another 6 horizontal trim pieces across the back edges of those same subassemblies. The number of middles and the length of the horizontal trim determine the size of the box rack set. Each Box2010 consists of 9 middles and 2 ends, while each BOX2020 consists of 19 middles and 2 ends. This illustration shows four complete columns First Horizontal and vertical pieces are cut to precise lengths Second: Horizontal and vertical pieces are assembled into ladder shaped subassemblies called middles and ends. Each middle requires 2 vertical pieces and 42 horizontal pieces. Each end also requires 2 vertical pieces but only 21 horizontal pieces, because ends only have horizontal pieces on one side. tributors, who is requesting that 10 units of BOX.2010 and 10 units of Box2020 be shipped Myer has just received an order for this popular product line from one of its retail dis out as soon as possible. This order arrives at an awkward time, in that the employees in Myer's job shop are busy working on a large custom wine cellar and none of the pieces or subassemblies that might speed the assembly of a BOX2010 or BOX2020 are currently in stock. Nonetheless, this retail distributor has been a valuable supply chain partner in Aggregate and Material Requirements Planning the pust, so Myer Wine Racking would like to fill this unexpected ordet for Band as Myer produces all items within its job shop. quickly as possible. Lead time on any item varies with boty of the tem R2020 as is needed 383 SW SKU ROK 2010 of Materials Data for Box Set Description 20 high x 10 column wide box rack set 20 high x 20 column wide box rack set Parent SKU None Lead Time Production Rate Svets per botoa R/2020 None sets per latos BOGOM 20 high middles 20 high ends 240K20E BERT20V ARTIH ARTIOT 10 modes per labotos 20 ends per labor how 20 high vertical pieces Horizontal rack piece 10 wide horizontal trim pieces 20 wide horizontal trim pieces BOX2010, BOX2020 BOX2010, BOX2020 RACK20M, RACK20 160 peces per bor hour RACK20M, RACK20 600 pieces per laborou BOX 2010 60 pieces per laborto BOX 2020 60 peces per lubos hou ARTZOT Questions 1. Draw standard product structure diagrams for the two finished goods discussed here. BOX2010 and BOX2020. Be certain to note the correct parent-to-child ratio required between each of the items in the diagram. 2. Draw time-phased product structure diagrams for a single BOX2010 and a single BOX2020, using the production rate information to estimate lead times for each item in the structure. Under the assumption of material requirements planning that work on a parent item cannot begin until all work on all child items is finished, how long does your diagram suggest Myer needs to produce one BOX2010 from nothing in stock? How long to produce one BOX2020? 3. How many labor-hours will be required in total to fill the retail distributor's ordert 4. Myer Wine Racking and Cellar Company is willing to reassign three employees to build this order, which it wishes to ship within three 8-hour days. Work out a sched ule for these three employees to accomplish this goal. outlining the timing of the production of all the items in the bill of materials. State any assumptions you make conceming how the Myer job shop works

Please answer questions 1-4 with explanation please

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock