Question: Case Study - Performing a DRP calculation at ABC Electronics . As the distribution inventory planning manager for ABC Electronics , you have been contacted

Case Study - Performing a DRP calculation at ABC Electronics . As the distribution inventory planning manager for ABC Electronics , you have been contacted by the manufacturing plant manager regarding the projected channel demand for a high- volume item stocked everywhere in the company's distribution channel , the K200-10 , DVD video recorder . The manufacturing manager needs to see the projected demand for this product over the next eight weeks. To begin the process , you have reviewed the bill of distribution kept in ABC's DRP system and have found that the distribution channel contains three echelons . You have diagramed the distribution channel and it appears follows: DC1 Regional Manufacturing Plant The DRP planning system also provides some critical information 1. All of the DCs are distribution facilities only . The plant is the only facility that makes the product 2. DCs 1 and 2 are supplied only from the Regional DC 3. The Regional DC is supplied directly from the Manufacturing Plant . 4. All of the facilities in the channel sell product to the customer , including the Manufacturing Plant . 5. Since all of the facilities are subject to independent demand , each facility has a forecast . The forecasts for DC1 and DC2 appear in the gross requirements rows on the DRP grid displayed on the next

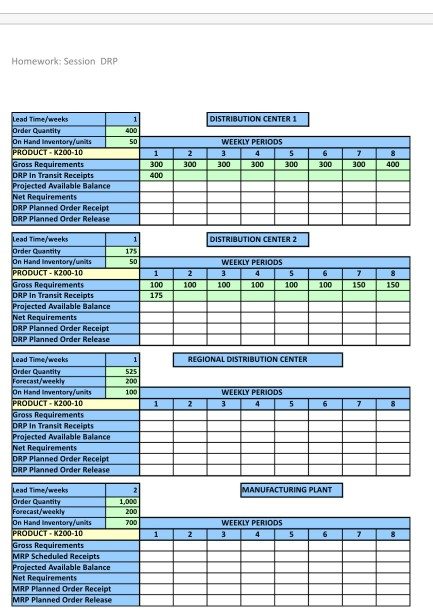

page . For the Regional DC , the forecast for the eight week planning horizon is 200 units each week . For the Manufacturing Plant , the forecast is also 200 units each week 6. The DRP grid for the K200-10 item also shows the DRP in transit receipts that are awaiting arrival at each of the facilities . 7. Based on this information and the planning data provided on the DRP gridsdisplayed on the next page , calculate the projected channel demand on the Manufacturing Plant for item K200-10 . Also , assist the manufacturing manager calculate the MRP plan

Homework: Session DRP 1 DISTRIBUTION CENTER 1 400 50 1 300 400 2 300 WEEKLY PERIODS 3 4 5 300 300 300 Lead Time/weeks Order Quantity on Hand Inventory/units PRODUCT - K200-10 Gross Requirements DRP in Transit Receipts Projected Available Balance Net Requirements DRP Planned Order Receipt DRP Planned Order Release 6 300 7 300 400 1 DISTRIBUTION CENTER 2 175 50 Lead Time/weeks Order Quantity on Hand Inventory/units PRODUCT - K200-10 Gross Requirements DRP in Transit Receipts Projected Available Balance Net Requirements DRP Planned Order Receipt DRP Planned Order Release 1 100 175 2 100 WEEKLY PERIODS 3 4 5 100 100 100 6 100 7 150 8 150 1 REGIONAL DISTRIBUTION CENTER 525 200 100 WEEKLY PERIODS 3 4 1 2 5 6 7 8 Lead Time/weeks Order Quantity Forecast/weekly On Hand Inventory/units PRODUCT - K200-10 Gross Requirements DRP In Transit Receipts Proje: Available Balance Net Requirements DRP Planned Order Receipt DRP Planned Order Release MANUFACTURING PLANT 2 1,000 200 700 WEEKLY PERIODS 3 4 1 2 5 6 7 Lead Time/weeks Order Quantity Forecast/weekly On Hand Inventory/units PRODUCT - K200-10 Gross Requirements MRP Scheduled Receipts Projected Available Balance Net Requirements MRP Planned Order Receipt MRP Planned Order ReleaseStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts