Question: Case Study: Surf Shaper, a surf warehouse in California, serves over 300 surf shops and retailers along the California coast. Surf Shaper places their boards

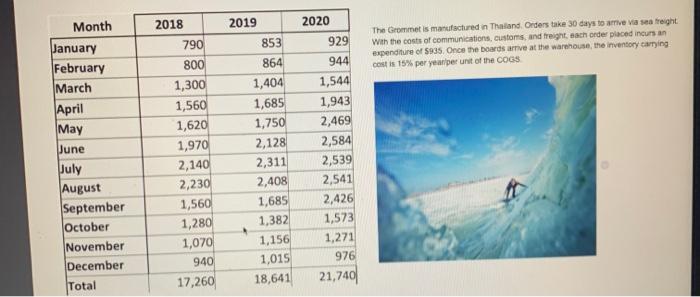

Case Study: Surf Shaper, a surf warehouse in California, serves over 300 surf shops and retailers along the California coast. Surf Shaper places their boards in surf shops on consignment and replaces the consignment stock from their warehouse as boards are sold, typically within 3 days. It is important that inventory be carefully managed. If the retail surf shops run out of Surf Shaper boards before the consignment inventory Is replaced, sales may be lost as customers choose otherboards Surf Shaper may also lose their shelf space within the retailer's shop it their supply chain proves unreliable. For this reason, Surf Shaper strives to maintain a 96% service level with their retailers The best-selling board for Surf Shaper is the Grommet, their 8-foot foam wide board, that is suitable for beginning and casual surfers. The Grommet retails for $400 and COGS is $150 per unit. The popularity of the Grommet has been steadily increasing over the past 3 years. The unit sales report for the past three years is displayed below. 2020 929 The Grommet is manufactured in Thailand. Orders take 30 days to arrive via sea freight With the costs of communications, customs and freight, each order placed incursan expenditure of $935. Once the boards arrive at the warehouse, the inventory carrying cost is 15% per year per unit of the COGS Month January February March April May June July August September October November December Total 2018 790 800 1,300 1,560 1,620 1,970 2,140 2,230 1,560 1,280 1,070 940 17,260 2019 853 864 1,404 1,685 1,750 2,128 2,311 2,408 1,685 1,382 1,156 1,015 18,641 944 1,544 1,943 2,469 2,584 2,539 2,541 2,426 1,573 1,271 976 21,740 1. Create a Sales Forecast showing a 15% increase in sales over 2020. 2. Use the 2021 Sales Forecast, determine the amount of Safety Stock Surf Shaper should keep on-hand to meet their service level goal. 3. Use the EOQ method to identity: The optimal order quantity (Q") . The number of orders to be completed The Re-Order Point Total ordering cost Inventory carrying cost Safety Stock Carrying cost COGS Total cost of the inventory plan

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts