Question: Ch . 1 2 : Inventory _ . Management: Reorder Point and Safety Stock _ Wheat _ Flour _ Manufacturing ( 5 pts ) Ch

Ch: InventoryManagement: Reorder Point and Safety StockWheatFlourManufacturing ptsCh: Inventory Management: Fixed Order Interval Fastenal

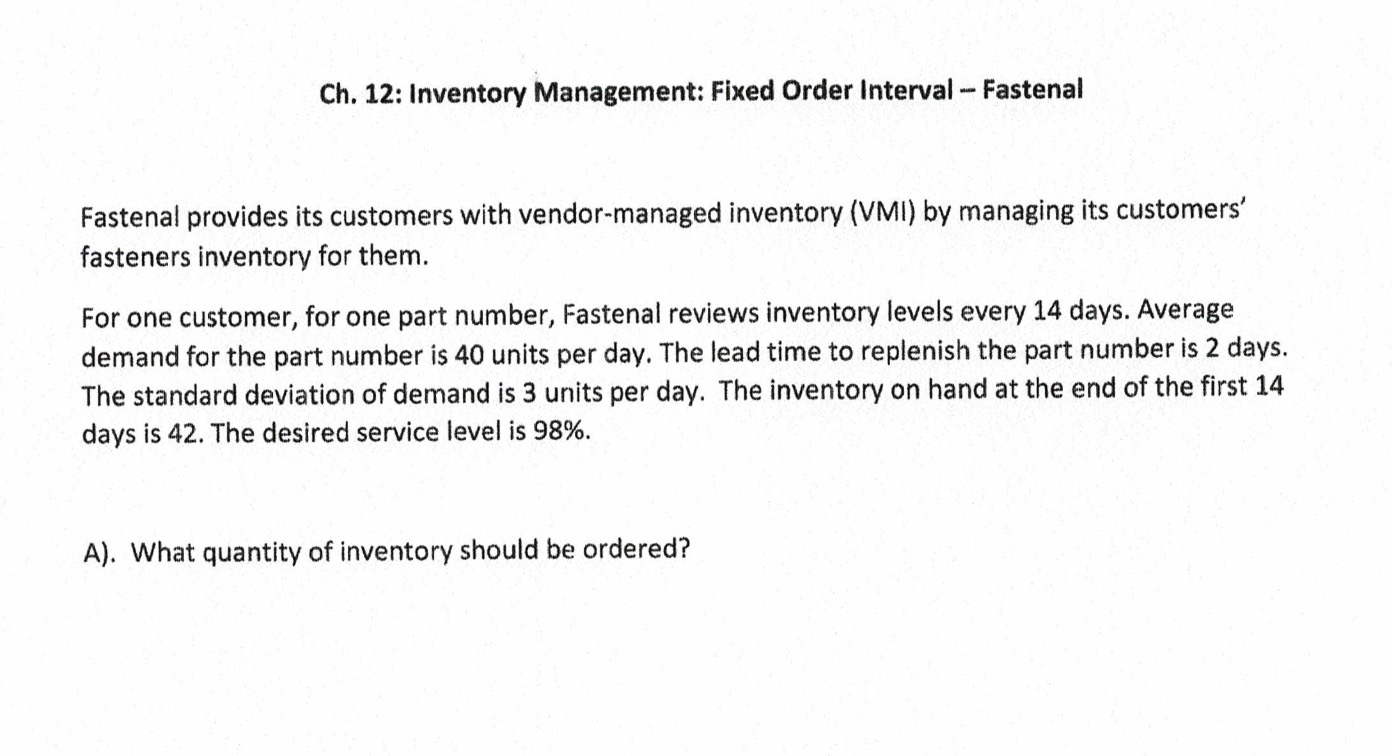

Fastenal provides its customers with vendormanaged inventory VMI by managing its customers'

fasteners inventory for them.

For one customer, for one part number, Fastenal reviews inventory levels every days. Average

demand for the part number is units per day. The lead time to replenish the part number is days.

The standard deviation of demand is units per day. The inventory on hand at the end of the first

days is The desired service level is

A What quantity of inventory should be ordered?

Wheat Flour Manufacturing produces flour which is sold to the restaurant industry. It provides you with

the following information:

Demand for wheat flour during lead time averages pounds;

Demand during lead time is described by a normal distribution that has a mean of pounds and a

standard deviation of pounds. Wheat Flour is willing to accept a stockout risk of no more than

Answer the following questions:

a What value of is appropriate?

b How much safety stock should be held?

c What reorder point should be used?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock