Question: change the flow matrix change tthe values that have been highlighted change highlighted values Q2) A small machine shop has three existing machines (M1 through

change the flow matrix

change tthe values that have been highlighted

change highlighted values

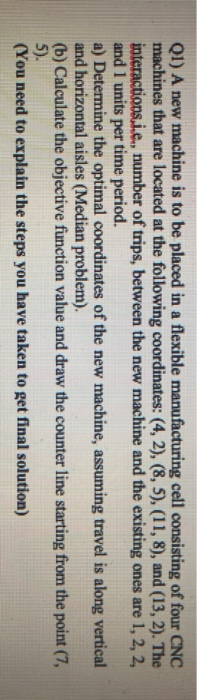

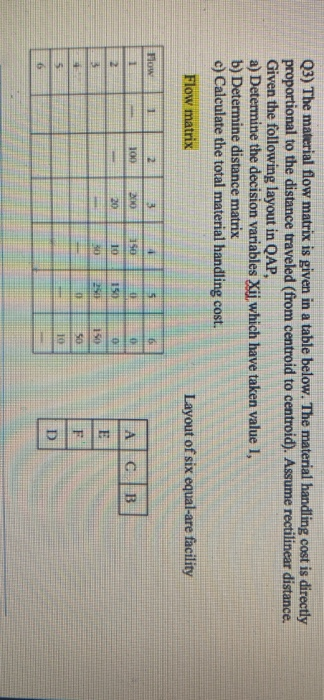

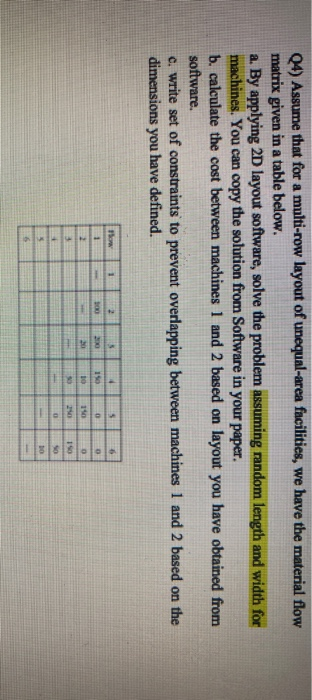

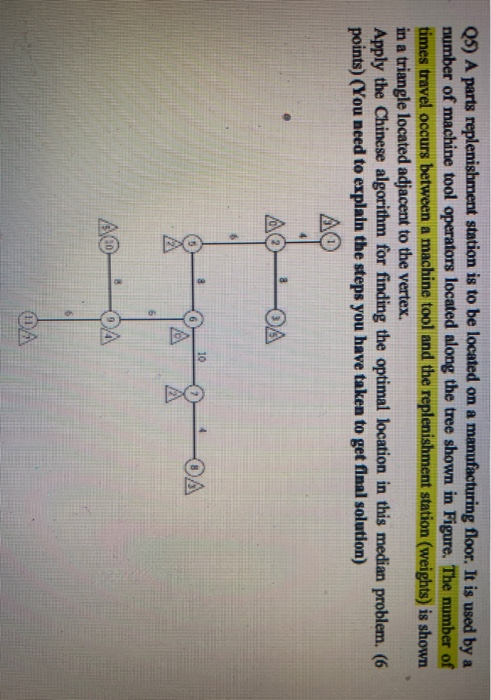

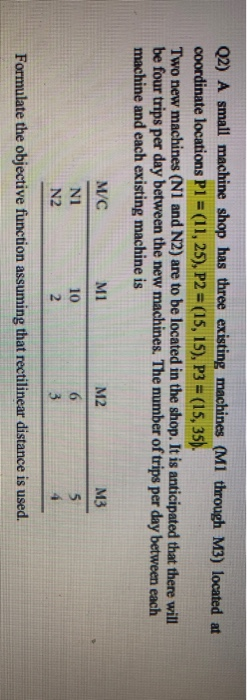

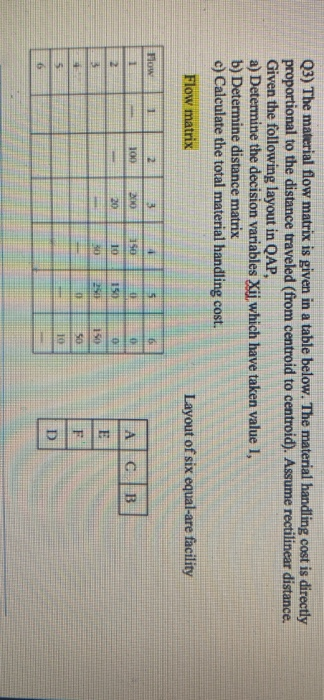

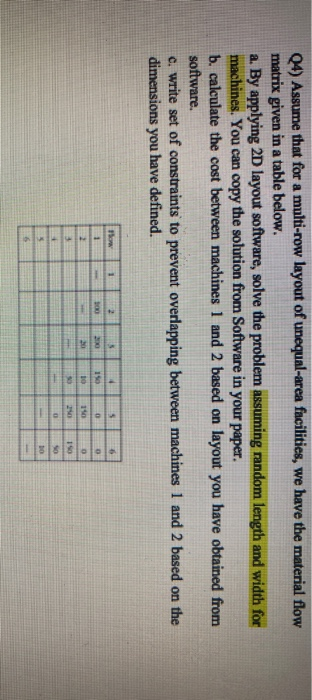

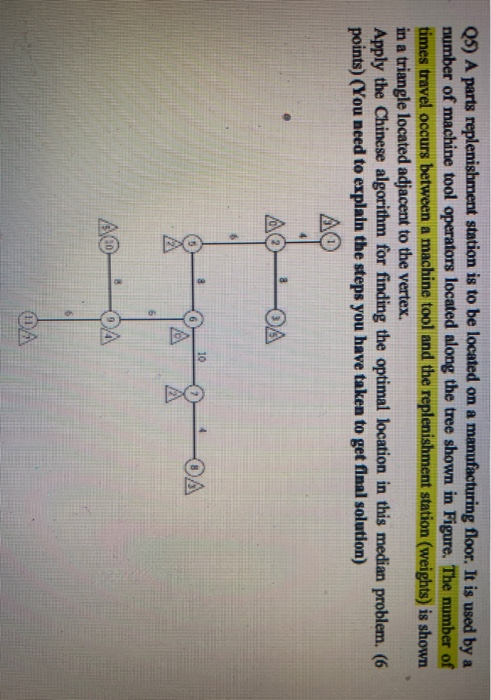

Q2) A small machine shop has three existing machines (M1 through M3) located at coordinate locations P1 = (11, 25), P2 = (15, 15), P3 = (15,35). Two new machines (N1 and N2) are to be located in the shop. It is anticipated that there will be four trips per day between the new machines. The number of trips per day between each machine and each existing machine is M/C M1 M2 M3 5 NI N2 10 2 6 3 Formulate the objective function assuming that rectilinear distance is used. 03) The material flow matrix is given in a table below. The material handling cost is directly proportional to the distance traveled (from centroid to centroid). Assume rectilinear distance. Given the following layout in QAP, a) Determine the decision variables Xii which have taken value 1, b) Determine distance matrix c) Calculate the total material handling cost. Flow matrix Layout of six equal-are facility How 1 2 3 5 1 100 150 C B 200 20 2 10 150 E 10 290 150 F 10 D 6 Q4) Assume that for a multi-row layout of unequal-area facilities, we have the material flow matrix given in a table below. a. By applying 2D layout software, solve the problem assuming random length and width for machines. You can copy the solution from Software in your paper. b. calculate the cost between machines 1 and 2 based on layout you have obtained from software. c. write set of constraints to prevent overlapping between machines 1 and 2 based on the dimensions you have defined. 2 6 200 150 O 1 2 3 10 D 1318 ISO + SO 10 5 05) A parts replenishment station is to be located on a manufacturing floor. It is used by a number of machine tool operators located along the tree shown in Figure. The number of times travel occurs between a machine tool and the replenishment station (weights) is shown in a triangle located adjacent to the vertex. Apply the Chinese algorithm for finding the optimal location in this median problem. (6 points) (You need to explain the steps you have taken to get final solution) 8 A -OA 10 OA AO OA Q1) A new machine is to be placed in a flexible manufacturing cell consisting of four CNC machines that are located at the following coordinates: (4,2), (8,5), (11,8), and (13,2). The interactions.i.e., number of trips, between the new machine and the existing ones are 1, 2, 2, and 1 units per time period. a) Determine the optimal coordinates of the new machine, assuming travel is along vertical and horizontal aisles (Median problem). (b) Calculate the objective function value and draw the counter line starting from the point (7, 5). (You need to explain the steps you have taken to get final solution) Q2) A small machine shop has three existing machines (M1 through M3) located at coordinate locations P1 = (11, 25), P2 = (15, 15), P3 = (15,35). Two new machines (N1 and N2) are to be located in the shop. It is anticipated that there will be four trips per day between the new machines. The number of trips per day between each machine and each existing machine is M/C M1 M2 M3 5 NI N2 10 2 6 3 Formulate the objective function assuming that rectilinear distance is used. 03) The material flow matrix is given in a table below. The material handling cost is directly proportional to the distance traveled (from centroid to centroid). Assume rectilinear distance. Given the following layout in QAP, a) Determine the decision variables Xii which have taken value 1, b) Determine distance matrix c) Calculate the total material handling cost. Flow matrix Layout of six equal-are facility How 1 2 3 5 1 100 150 C B 200 20 2 10 150 E 10 290 150 F 10 D 6 Q4) Assume that for a multi-row layout of unequal-area facilities, we have the material flow matrix given in a table below. a. By applying 2D layout software, solve the problem assuming random length and width for machines. You can copy the solution from Software in your paper. b. calculate the cost between machines 1 and 2 based on layout you have obtained from software. c. write set of constraints to prevent overlapping between machines 1 and 2 based on the dimensions you have defined. 2 6 200 150 O 1 2 3 10 D 1318 ISO + SO 10 5 05) A parts replenishment station is to be located on a manufacturing floor. It is used by a number of machine tool operators located along the tree shown in Figure. The number of times travel occurs between a machine tool and the replenishment station (weights) is shown in a triangle located adjacent to the vertex. Apply the Chinese algorithm for finding the optimal location in this median problem. (6 points) (You need to explain the steps you have taken to get final solution) 8 A -OA 10 OA AO OA Q1) A new machine is to be placed in a flexible manufacturing cell consisting of four CNC machines that are located at the following coordinates: (4,2), (8,5), (11,8), and (13,2). The interactions.i.e., number of trips, between the new machine and the existing ones are 1, 2, 2, and 1 units per time period. a) Determine the optimal coordinates of the new machine, assuming travel is along vertical and horizontal aisles (Median problem). (b) Calculate the objective function value and draw the counter line starting from the point (7, 5). (You need to explain the steps you have taken to get final solution)

change the flow matrix

change the flow matrix  change tthe values that have been highlighted

change tthe values that have been highlighted  change highlighted values

change highlighted values