Question: Chapter 1 MRP Example - Inventory Planning Recently, Phil Harris, the production control manager at McLaren Engine works, an article on Time-Phased Requirements Planning. He

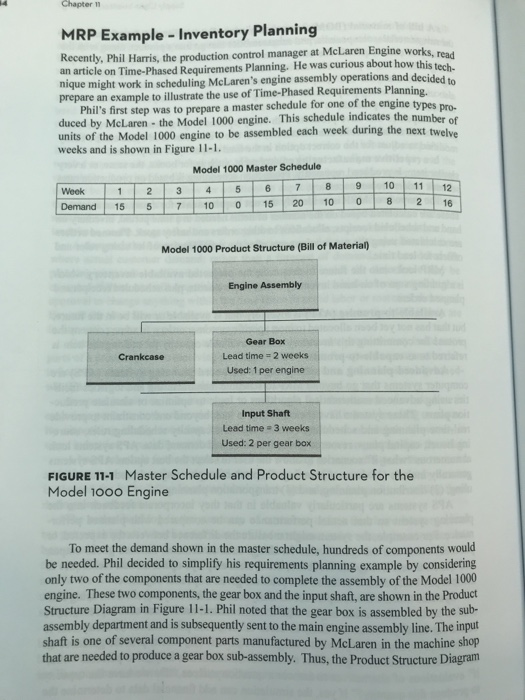

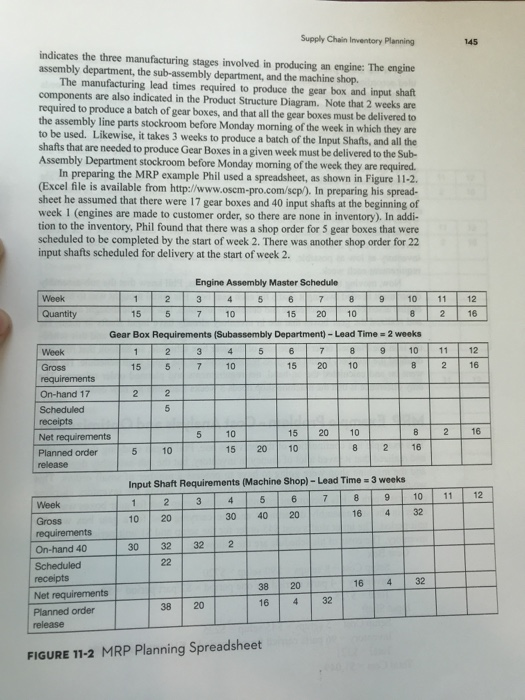

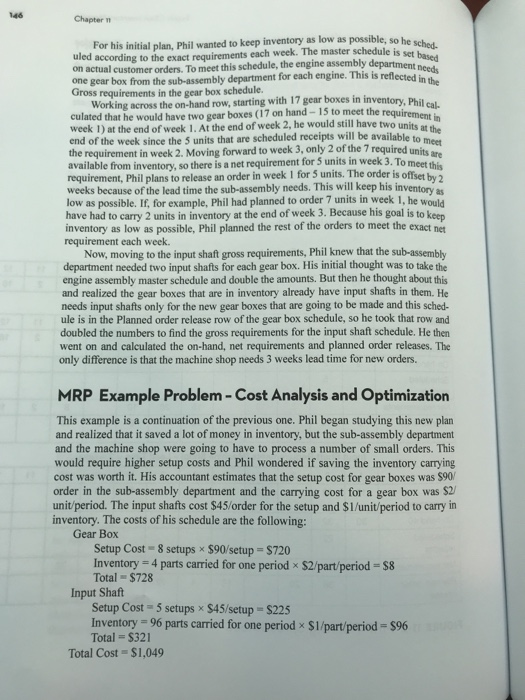

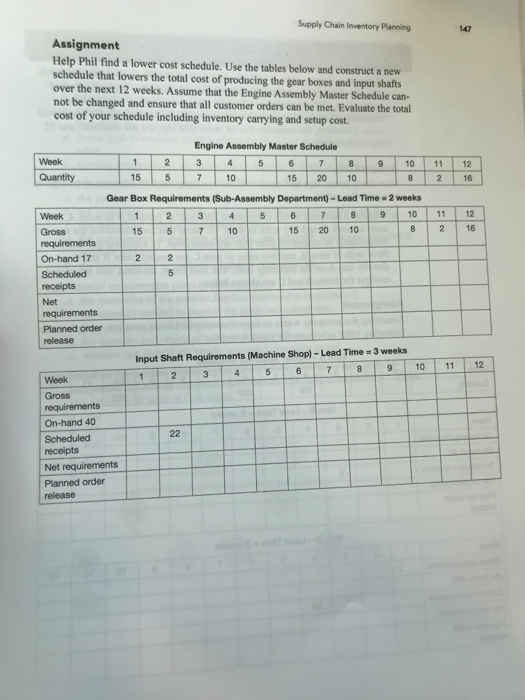

Chapter 1 MRP Example - Inventory Planning Recently, Phil Harris, the production control manager at McLaren Engine works, an article on Time-Phased Requirements Planning. He was curious about how this tech nique might work in scheduling McLaren's engine assembly operations and decided to prepare an example to illustrate the use of Time-Phased Requirements Plannine. Phil's first step was to prepare a master schedule for one of the engine types o duced by McLaren - the Model 1000 engine. This schedule indicates the number of units of the Model 1000 engine to be assembled each week during the next twelve weeks and is shown in Figure 11-1. Model 1000 Master Schedule Week 1 2 3 4 5 6 7 8 9 10 11 12 Demand 15 5 7 100 15 20 100 Model 1000 Product Structure (Bill of Material) Engine Assembly Crankcase Gear Box Lead time = 2 weeks Used: 1 per engine Input Shaft Lead time = 3 weeks Used: 2 per gear box FIGURE 11-1 Master Schedule and Product Structure for the Model 1000 Engine To meet the demand shown in the master schedule, hundreds of components would be needed. Phil decided to simplify his requirements planning example by considering only two of the components that are needed to complete the assembly of the Model 1000 engine. These two components, the gear box and the input shaft, are shown in the Product Structure Diagram in Figure 11-1. Phil noted that the gear box is assembled by the sub- assembly department and is subsequently sent to the main engine assembly line. The input shaft is one of several component parts manufactured by McLaren in the machine shop that are needed to produce a gear box sub-assembly. Thus, the Product Structure Diagram Supply Chain Inventory Planning indicates the three manufacturing stages involved in producing an engine: The engine assembly department, the sub-assembly department, and the machine shop The manufacturing lead times required to produce the gear box and input shaft components are also indicated in the Product Structure Diagram. Note that 2 weeks are required to produce a batch of gear boxes, and that all the gear boxes must be delivered to the assembly line parts stockroom before Monday morning of the week in which they are to be used. Likewise, it takes 3 weeks to produce a batch of the Input Shafts, and all the shafts that are needed to produce Gear Boxes in a given week must be delivered to the Sub- Assembly Department stockroom before Monday moming of the week they are required. In preparing the MRP example Phil used a spreadsheet, as shown in Figure 11-2. (Excel file is available from http://www.oscm-pro.com/sep/). In preparing his spread- sheet he assumed that there were 17 gear boxes and 40 input shafts at the beginning of week 1 (engines are made to customer order, so there are none in inventory). In addi- tion to the inventory, Phil found that there was a shop order for 5 gear boxes that were scheduled to be completed by the start of week 2. There was another shop order for 22 input shafts scheduled for delivery at the start of week 2. 11 12 11 2 16 Engine Assembly Master Schedule Week 1 2 3 4 5 6 7 8 9 10 Quantity 1557 10 15 2010 Gear Box Requirements (Subassembly Department) - Lead Time = 2 weeks Wook 2 3 4 5 6 7 8 9 10 Gross 15 5 7 10 15 20 10 B requirements On-hand 17 2 2 Scheduled 5 receipts Net requirements 10 15 20 10 8 Planned order 5 / 10 15 20 10 8 release Input Shaft Requirements (Machine Shop) - Lead Time = 3 weeks Week 1 2 3 4 5 6 7 8 9 10 Gross 10 20 30 40 20 16 4 32 requirements On-hand 40 30 32 322 Scheduled receipts 38 20 164 32 Net requirements 38 Planned order 164 release 11 aments FIGURE 11-2 MRP Planning Spreadsheet Chapter e. This is reflected in the For his initial plan, Phil wanted to keep inventory as low as possible, so he uled according to the exact requirements each week. The master schedule is a on actual customer orders. To meet this schedule, the engine assembly department one gear box from the sub-assembly department for each engine. This is reflected Gross requirements in the gear box schedule. Working across the on-hand row. starting with 17 gear boxes in inventory, Phi mory, Phil cal. culated that he would have two gear boxes (17 on hand - 15 to meet the requirem week 1) at the end of week 1. At the end of week 2, he would still have two units end of the week since the 5 units that are scheduled receipts will be available to the requirement in week 2. Moving forward to week 3, only 2 of the 7 required unite available from inventory, so there is a net requirement for 5 units in week 3. To mente requirement, Phil plans to release an order in week 1 for 5 units. The order is offset by weeks because of the lead time the sub-assembly needs. This will keep his inventory s inventory as low as possible. If, for example, Phil had planned to order 7 units in week 1. he would have had to carry 2 units in inventory at the end of week 3. Because his goal is to keep inventory as low as possible, Phil planned the rest of the orders to meet the exact me requirement each week. Now, moving to the input shaft gross requirements, Phil knew that the sub-assembly department needed two input shafts for each gear box. His initial thought was to take the engine assembly master schedule and double the amounts. But then he thought about this and realized the gear boxes that are in inventory already have input shafts in them. He needs input shafts only for the new gear boxes that are going to be made and this sched- ule is in the Planned order release row of the gear box schedule, so he took that row and doubled the numbers to find the gross requirements for the input shaft schedule. He then went on and calculated the on-hand, net requirements and planned order releases. The only difference is that the machine shop needs 3 weeks lead time for new orders. MRP Example Problem - Cost Analysis and Optimization This example is a continuation of the previous one. Phil began studying this new plan and realized that it saved a lot of money in inventory, but the sub-assembly department and the machine shop were going to have to process a number of small orders. This would require higher setup costs and Phil wondered if saving the inventory carrying cost was worth it. His accountant estimates that the setup cost for gear boxes was $90 order in the sub-assembly department and the carrying cost for a gear box was $2 unit period. The input shafts cost $45/order for the setup and $1/unit/period to carry in inventory. The costs of his schedule are the following: Gear Box Setup Cost = 8 setups * $90/setup = $720 Inventory = 4 parts carried for one period * $2/part/period=$8 Total = $728 Input Shaft Setup Cost - 5 setups * $45/setup - $225 Inventory = 96 parts carried for one period Sl/part/period - $96 Total = $321 Total Cost = $1,049 Supply Chain Inventory Planning total cost of products Assembly Mastere Assignment Help Phil find a lower cost schedule. Use the tables below and construct a new schedule that lowers the total cost of producing the gear boxes and input shafts over the next 12 weeks. Assume that the Engine Assembly Master Schedule can- not be changed and ensure that all customer orders can be met. Evaluate the total cost of your schedule including inventory carrying and setup cost. the total 11 2 12 16 11 12 210 Engine Assembly Master Schedule Week 1 2 3 4 5 6 7 8 9 10 Quantity 15 5 7 10 15 20 10 8 Gear Box Requirements (Sub-Assembly Department) - Lead Time = 2 weeks Week 1 2 3 4 5 6 7 8 9 10 Gross 155 7 10 15 20 10 8 requirements On-hand 17 2 2 Scheduled led 5 receipts Net requirements Planned order release Input Shaft Requirements (Machine Shop) - Lead Time = 3 weeks 3 2 4 1 6 5 Week 7 8 10 9 Gross requirements On-hand 40 Scheduled receipts Net requirements Planned order release 11