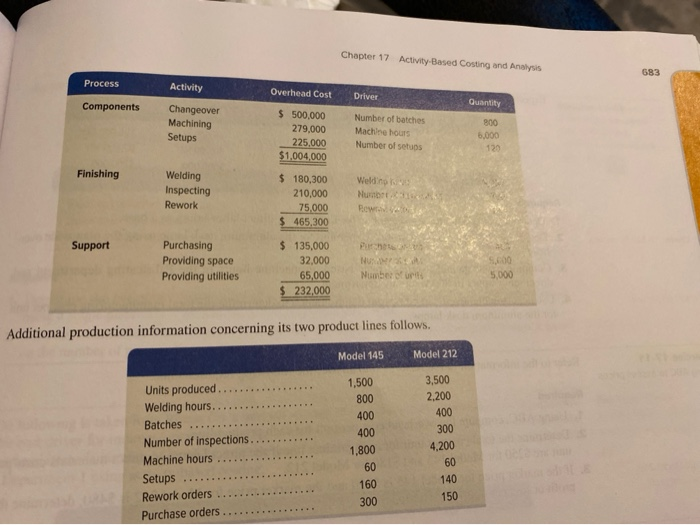

Question: Chapter 17 Activity Based Costing and Analysis 683 Process Activity Overhead Cost Driver Quantity Components Changeover Machining Setups $ 500.000 279.000 225,000 $1,004,000 Number of

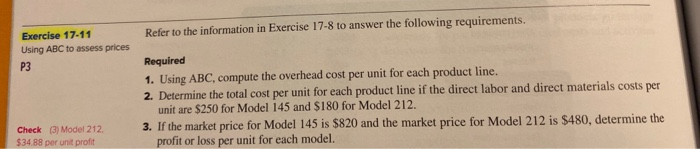

Chapter 17 Activity Based Costing and Analysis 683 Process Activity Overhead Cost Driver Quantity Components Changeover Machining Setups $ 500.000 279.000 225,000 $1,004,000 Number of batches Machinebours Number of setos 800 5,000 120 Finishing Welding Inspecting Rework Weldo Nutr. $ 180,300 210,000 75.000 $ 465,300 Support Purchasing Providing space Providing utilities $ 135,000 32,000 65,000 232,000 Purch NUM Numbers 5.000 Additional production information concerning its two product lines follows. Model 145 Model 212 Units produced Welding hours Batches Number of inspections Machine hours Setups Rework orders Purchase orders 1,500 800 400 400 1,800 60 160 300 3,500 2,200 400 300 4,200 60 140 150 Refer to the information in Exercise 17-8 to answer the following requirements, Exercise 17-11 Using ABC to assess prices P3 Required 1. Using ABC, compute the overhead cost per unit for each product line. 2. Determine the total cost per unit for each product line if the direct labor and direct materials costs per unit are $250 for Model 145 and $180 for Model 212. 3. If the market price for Model 145 is $820 and the market price for Model 212 is $480, determine the profit or loss per unit for each model. Check (3) Model 212 $34.88 per unit profit

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts