Question: Chapter 2 To Outsource or To Design Internally? A Case of LED Manufacturer 2.1 Company Profiles 2.3.1 Company Background Company A has been established since

Chapter 2 To Outsource or To Design Internally? A Case of LED Manufacturer 2.1 Company Profiles 2.3.1 Company Background Company A has been established since 1999 and is located in Penang Island. The company is recognised as one of the leading engineering company that manufacture various green technology products including LED lighting products and system. Founded about 20 years ago, the company has been investing millions into its research and development activities, and has cooperatively innovate with academic institutions as well as international giant player to develop improved lighting and illumination solutions that will generate minimal impact to the environment. These quality products have been patented and received international certification awards from Certified European Standards (CE) and SIRIM Malaysian.

After years of hardwork and intensive commitment on research and designs, the company has able to offer various extensive LED lighting products, to be used in residential, commercial as well as public sectors, which could be customised according to the customers needs. Utilising the latest LED technology, the company has pentrated not only in the transportation and automobile industry, but also architectural building. To date the company exports to various overseas markets, such as United States, South Africa, China and Middle East. Whilst the company has various international markets, its marketing plan remained uniform. Yet, its strategy is to concentrating on introducing various products by catering to the indvidual needs of the market market specific product, whereby there is difference in designs and specifications.

2.3.2 Supply Chain Orientation Company A built its reputation as LED supplier based on its capability to provide reliable and quality products. Underpinning this success was a close relationship with its supply base. The reasons for them to maintain exclusive relationship with suppliers was due to the characteristics of lighting application, which present unique design challenges. According to its R & D manager, different areas of store outlets for example, entails different LED lighting systems to enhance product appearance. This requirement requires not only large volumes, but hefty variations of LED components, which could vary according to the colour 2 temperature (light wavelength) and light intensity. In a large-scale installation, this may become a challenge to them, as to maintain a consistent colour temperature and intensity might be a daunting task. When high volumes of LED lighting PCBs and modules are manufactured, the probability of inducing stress related failures can increase during the manufacturing process. Sometimes, these fractures although very small and are not visible during the visual inspection, it can threaten the products robustness, leading to shorter lifetime or reliability. The complicated lighting systems, with a wide range of applications ranging from inhome to retail to outdoor lighting causes great challenges in the design process. This explains the companys motive to outsource the design function to suppliers.

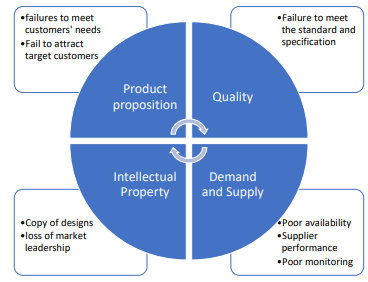

However, in the mid-2000s, this arena began to change. The company found that its loyalty to its suppliers turned from being an asset to a liability. Whilst its competitors were increasingly importing materials and components which was cheaper, the company was stuck to a more expensive operations costs, with their customers began to desert them. At Company A, the design function in the past is fully outsourced and managed in isolation with other departments, which increased the risks of false or inaccurate product propositioning. The companys strategy in the past, which had allowed their suppliers to take control of the design process, at the end, had increased the risks, since they are becoming over-dependence with suppliers. It became difficult for them to fine-tune or change the product designs that are tailored to customers needs, reducing their responsiveness and flexibility performance. This eventually led to devastating economic consequences on the business profits.

This phenomenon has led company A to rebuilt itself, through sourcing configuration and taking control of the product design process. Underlying their existing strategy is the need to enhance responsiveness through speeding up their product launched, through developing in-house design capability and collaboration with raw material suppliers.

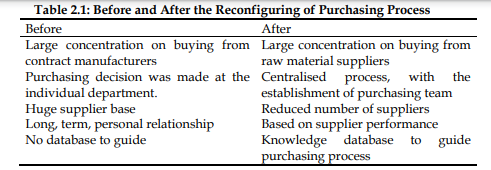

(Sourcing and Purchasing Process Re-configuration) The first and foremost important step took by Company A was to review its purchasing process and introduced new ways of buying materials as well as LED components. Previously, the purchasing decision was left to the managers who were involved with individual product lines. The process was depending in longterm supply chain relationships where the supplier possessed responsibility for design and product development. These relationships which were characterised by long-term, close and paternal were considered a low-risk strategy and worked well. Yet, by the mid of 2000s, the company ended up with a huge supplier base, high product costs and unattractive product range. They realised that these relationships, had turned from low-risk strategy to a new high-posed risk. Their over reliance on suppliers had led them into increased uncertainty of business transactions. The close and personal relationships further made it difficult for the company to regulate and evaluate their suppliers performance.

In order to address this problem, Company A decided to centralise its purchasing processes. In the old structure, each purchasing process was made individually. The decentralised purchasing created havoc. Different projects using the same component, end up paying 20 different prices for its raw materials from the same supplier. Yet, in this new structure, the purchasing team plays a role in identifying new suppliers, who can offer Company A good quality LED components at the competitive prices. This practice helps them to leverage purchase volume for better pricing, develop a stronger relationship with suppliers and maintained professional control over the purchasing process.

The next step taken was to re-evaluate the existing suppliers, and disengage those who did not offer them value for money, quality, reliability, flexibility, and innovative product and process. In relating to this practice, they have also maintained a strong relationship with raw material suppliers, which had previously worked well. Rather than depending on local suppliers, Company A has started to seek overseas suppliers for its raw materials. This step was taken since, importing certain raw materials from abroad will be much cheaper, whilst at the same time maintaining quality. Although this practice may appear appealing, it is not without risks. With materials having to travel further, different languages, and unanticipated political and economic stability, Company A found themselves faced higher supply chain risks, greater than the potential savings offered. Hence, to reduce such risks or diversify the effect of risks, they decided to source from different parts of the world. This practice was seen to help them in becoming over-depending on a narrow supply base. In addition, it also enables the company to switch production to avoid supply chain disruption caused by instable political, economic or natural disaster.

When asked about the proportion of contract manufacturers and raw material suppliers, the companys management team explained that they have moved from large concentration of contract manufacturers and small base of raw material suppliers to a large concentration of raw material suppliers and small base of contract manufacturers. The apposite direction was made, considering that product design is their core value and this function poses high risks. In the past, Company A were unable to adapt to a more agile supply chain strategy, which has been adopted by their competitors, since they were over-dependence on their suppliers to manage their design function.

As part of their strategy to reduce the material costs and speed up the process, they bought directly from suppliers, eliminating the intermediaries. To facilitate this process, Company A has developed a knowledge database consisting of the prices of raw materials, technical qualities of materials, the value of buying from one supplier as opposed to buying from another, and costs of transportation involved. These steps were taken to reduce the purchasing risks, and help the team to make an informed decision. As the purchasing team is buying directly from the raw material suppliers, they need to be able have the technical knowledge in order to judge whether the suppliers are capable to 4 produce the required components to the stated specification. Hence, this knowledge database helps in maintaining and providing access to such knowledge to the purchasing team.

(Building in-house Product Design Capabilities) As most products have a limited and even predictable lifecycle, companies in general need to continuously looking for new products to design, develop and bring to market. Equally important is the ability to identify the customers needs and expectations to ensure products are produced with the required attributes. At the Company A, the major contributor to its recovery is due to the substantial investment in research and development, design and technology. Product Specialist and Specialist Designers become a big part of the companys investment. By taking over the control of design from their suppliers and hiring more specialist designers to design in-house, Company A has become an upstream vertically integrated company. Vertical integration can offer the company a strategic opportunity in terms of cost reduction, higher quality, timely delivery and inventory reduction, since the company has a control over the supply chain processes. Yet, this strategy appears to work best, if the company has large market share, and talents, as with the case of Company A.

By bringing the design process to in-house, Company A is able to influence both the upstream and downstream of supply chain. Marketing department or sales people are now able to communicate information on customers requirements to designers easily, who in turn communicate these latest needs to the suppliers. Similarly, the products that do not sell well in the market can also be communicated easily to production team, so that those product lines can be stopped or reduced, and replace with another that sell well. This helps in speeding up replenishment times and reducing inventory. Notwithstanding this, they are also able to engage in postponement strategy, in which final assembly of products will only take place, once they receive the updated 5 information on market demands. With this practice, they are able to reduce inventory of finished goods in the pipeline and replace it work in progress. This illustrates that the greater the involvement of various functions of the business in product design, the more significant positive impact will be realised by the company, which are not only limited to completion time, but also cost, quality and flexibility.

In Company A, the product development team is observed to be consisted of members from related functions such as product engineering, marketing, finance, manufacturing, logistics, purchasing and business planning. This allows them to take a proactive approach to design. Rather than seeing the process as just another activity, they see the design function as supply chain process that would creates novel ideas and value added. In comparison with previous practice, Company A is now able to coordinate well with different product design teams. By designing in-house, designers from different sections can communicate ideas and compare the products that they are designing or developing more quickly. They can even identify if products across all sections will sit together as a complete product ranges offered by the manufacturing firm. This eventually will help minimising the risks of outsourcing design to external designers who may design products that are in-congruent with the existing product ranges or other products designed internally. Additionally, by bringing the process in-house, it also offers opportunity for the company to perform manufacturability and value engineering activities. These activities concerned with improvement of a products design, production, maintainability and use, which have an obvious impact on cost reduction. In these activities, the product development teams work together finding ways of how the production costs could be reduced by altering the designs. They yield value improvement by focussing on achieving the necessary functional specifications to meet the customer needs in an optimal way. This practice alone, could help the company to typically reduce costs between 20 to 40 per cent, without jeopardising the quality.

With the new transformation, the design or product development teams have also a new responsibility. They are now intrinsically linked to the purchasing process, in which they have the final say in terms of product specification that should be used by the suppliers. In another word, they are held responsible for identifying and coordinating the work of suppliers. By allowing the designers to be part of the final purchasing decision, Company A is able to control or reduce its exposure to supply chain risks, due to failed product designs, since this practice. helps them to ensure that suppliers are producing raw components and materials required by Company A; and fitted in terms of quality. Hence, we could say that Company As decision to bring in the designers internally not only to attract customers back, but this strategy could help them in managing supply chain risks

(FIgure 2.1) 6 Figure 2.1: Risks that are reduced due to the configuring process

Please read the case given To outsource or to design internally? The case of an LED application manufacturer, and answer the following questions:

- The company has engaged in global sourcing as part of its purchasing strategy. Discuss briefly the advantages and risks of such practice

- Discuss how the company could reduce the risks of global sourcing.

- Outsourcing has emerged as one of the popular supply chain practice, adopted since 1990s. Why do you think that some of the business processes are not suitable to be outsourced?

- The company has employed vertical integration practice. What does vertical integration means? Do you think that vertical integration is suitable for every industry? Why? Why do you think that vertical integration is a feasible approach in the case studied?

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts