Question: Chapter 4 Class activity part 2 Q1: Patterson Electronics supplies microcomputer circuitry to a company that incorporates microprocessors into refrigerators and other home appliances. One

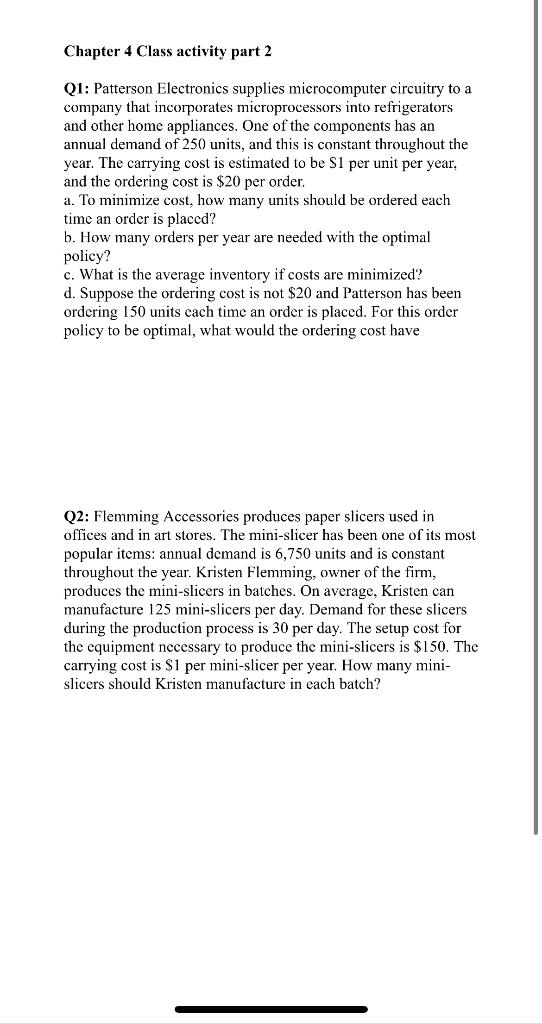

Chapter 4 Class activity part 2 Q1: Patterson Electronics supplies microcomputer circuitry to a company that incorporates microprocessors into refrigerators and other home appliances. One of the components has an annual demand of 250 units, and this is constant throughout the year. The carrying cost is estimated to be $1 per unit per year, and the ordering cost is $20 per order. a. To minimize cost, how many units should be ordered each time an order is placed? b. How many orders per year are needed with the optimal policy? c. What is the average inventory if costs are minimized? d. Suppose the ordering cost is not $20 and Patterson has been ordering 150 units each time an order is placed. For this order policy to be optimal, what would the ordering cost have Q2: Flemming Accessories produces paper slicers used in offices and in art stores. The mini-slicer has been one of its most popular items: annual demand is 6,750 units and is constant throughout the year. Kristen Flemming, owner of the firm, produces the mini-slicers in batches. On average, Kristen can manufacture 125 mini-slicers per day. Demand for these slicers during the production process is 30 per day. The setup cost for the equipment necessary to produce the mini-slicers is $150. The carrying cost is $1 per mini-slicer per year. How many minislicers should Kristen manufacture in each batch

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts