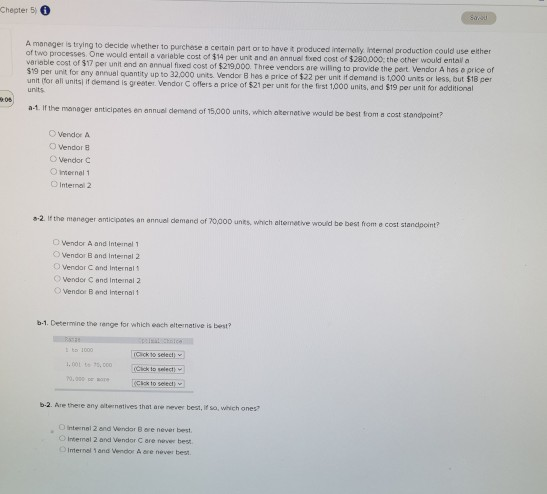

Question: Chapter 5 A manager is trying to decide whether to purchase a certain part or to have produced internally internal production could use either of

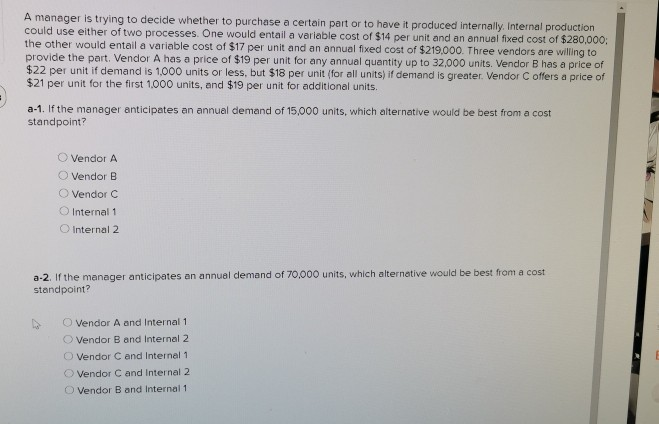

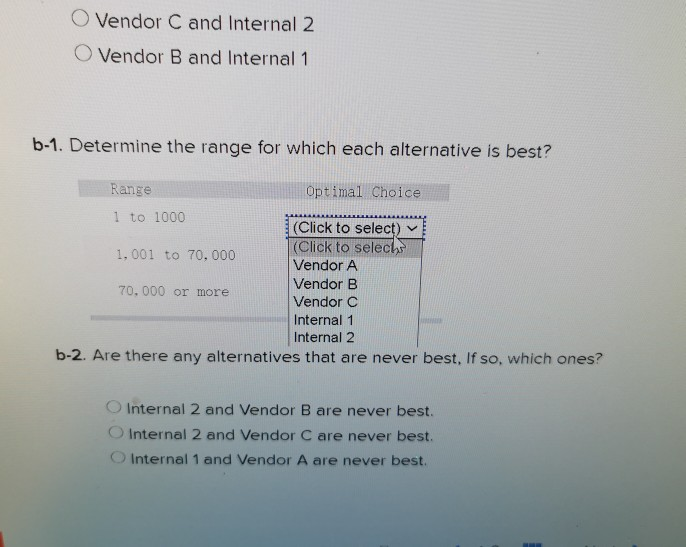

Chapter 5 A manager is trying to decide whether to purchase a certain part or to have produced internally internal production could use either of two processes. One would entaila variable cost of $14 per unit and an annual fed cost of $200.000: the other would entala variable cost of $17 per unit and an annual fixed cost of $219.000 Three vendors are willing to provide the part. Vendar A has a price of $19 per unit for any annual quantity up to 32.000 units Vendor Bhese price of $22 per unit If demand is 1000 units or less, but $18 per unit for all units if demand is greater Vendor C offers a price of $21 per unit for the first 1000 units, and $19 per unit for additional units 02:00 a-1. If the manager anticipates en annual demand of 15,000 units, which alternative would be best from a cost standpoint? Vendor A Vendor Vendor Internal 1 Internal 2 3-2. If the manager anticipates an annual demand of 70,000 unts, which alterative would be best from a cost standaoint? Vendor A and Internal 1 Vendor Band internal 2 Vendor Cand Internal Vender C and internal 2 Vendor Band Internal 1 b-1. Determine the range for which each alternative is best? to 1000 Ick to select 1.not to 5.000 19.00 Click to (COX1o Select -2. Are there any alternatives that are never best, if so, which ones! Internal 2 and Vendor Bare never best Intemal 2 and Vendor C are never best Internal and Vendor Aare never best A manager is trying to decide whether to purchase a certain part or to have it produced internally. Internal production could use either of two processes. One would entail a variable cost of $14 per unit and an annual fixed cost of $280,000: the other would entail a variable cost of $17 per unit and an annual fixed cost of $219.000. Three vendors are willing to provide the part. Vendor A has a price of $19 per unit for any annual quantity up to 32,000 units. Vendor B has a price of $22 per unit if demand is 1.000 units or less, but $18 per unit (for all units) if demand is greater. Vendor offers a price of $21 per unit for the first 1000 units, and $19 per unit for additional units. a-1. If the manager anticipates an annual demand of 15,000 units, which alternative would be best from a cost standpoint? O Vendor A Vendor B O Vendor C Internal 1 Internal 2 a-2. If the manager anticipates an annual demand of 70,000 units, which alternative would be best from a cost standpoint? Vendor A and Internal 1 Vendor Band Internal 2 O Vendor C and Internal 1 Vendor C and Internal 2 O Vendor Band Internal 1 O Vendor C and Internal 2 Vendor B and Internal 1 b-1. Determine the range for which each alternative is best? Range Optimal Choice 1 to 1000 (Click to select) (Click to selech 1,001 to 70.000 Vendor A Vendor B 70.000 or more Vendor C Internal 1 Internal 2 b-2. Are there any alternatives that are never best, If so, which ones? Internal 2 and Vendor B are never best. O Internal 2 and Vendor Care never best. Internal 1 and Vendor A are never best

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock