Question: Chapter 6: 21. Product tolerances are often called a) SPC b) Product drawings c) Product descriptions d) Process capability e) Product specifications 22. Six-sigma quality

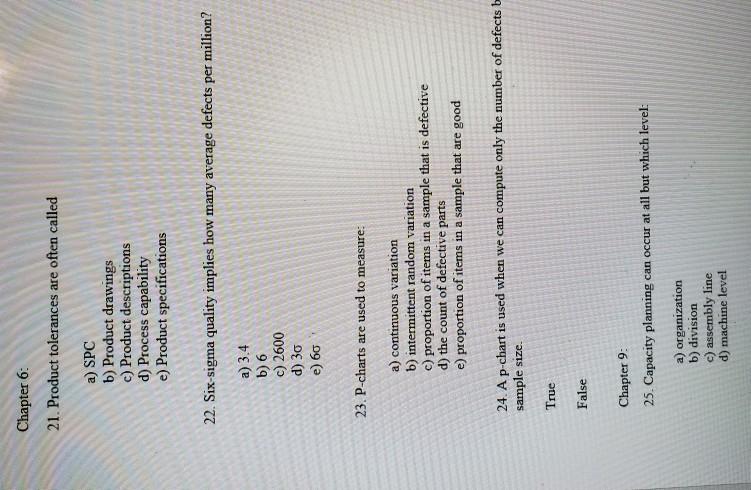

Chapter 6: 21. Product tolerances are often called a) SPC b) Product drawings c) Product descriptions d) Process capability e) Product specifications 22. Six-sigma quality implies how many average defects per million? a) 3.4 b) 6 c) 2600 d) 30 e) 60 23. P-charts are used to measure: a) continuous variation b) intermittent random variation c) proportion of items in a sample that is defective d) the count of defective parts e) proportion of items in a sample that are good 24. A p-chart is used when we can compute only the number of defects sample size. True False Chapter 9: 25. Capacity planning can occur at all but which level: a) organization b) division c) assembly line d) machine level

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock