Question: Chapter 8 - Quantity and Inventory Case 8-2: Throsel-Teskey Drilling On Wednesday, June 12, Alison Burkett, purchasing manager at Throsel-Teskey Drilling Inc. (Throsel- Teskey) in

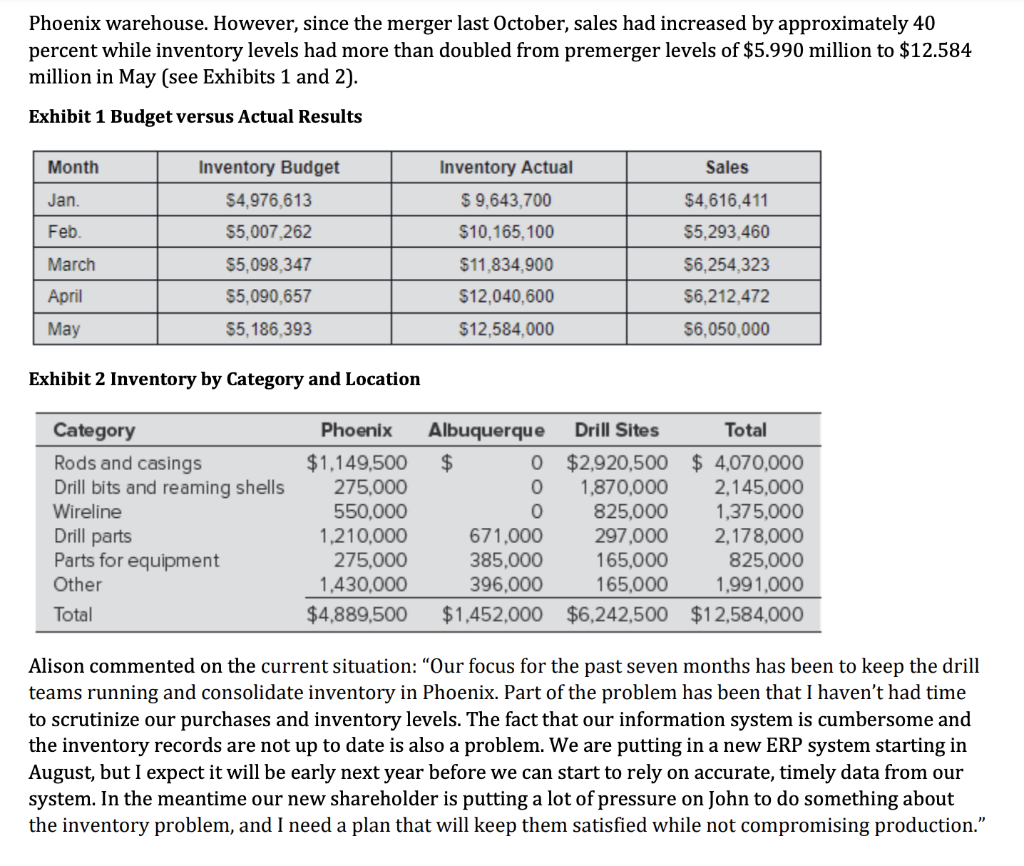

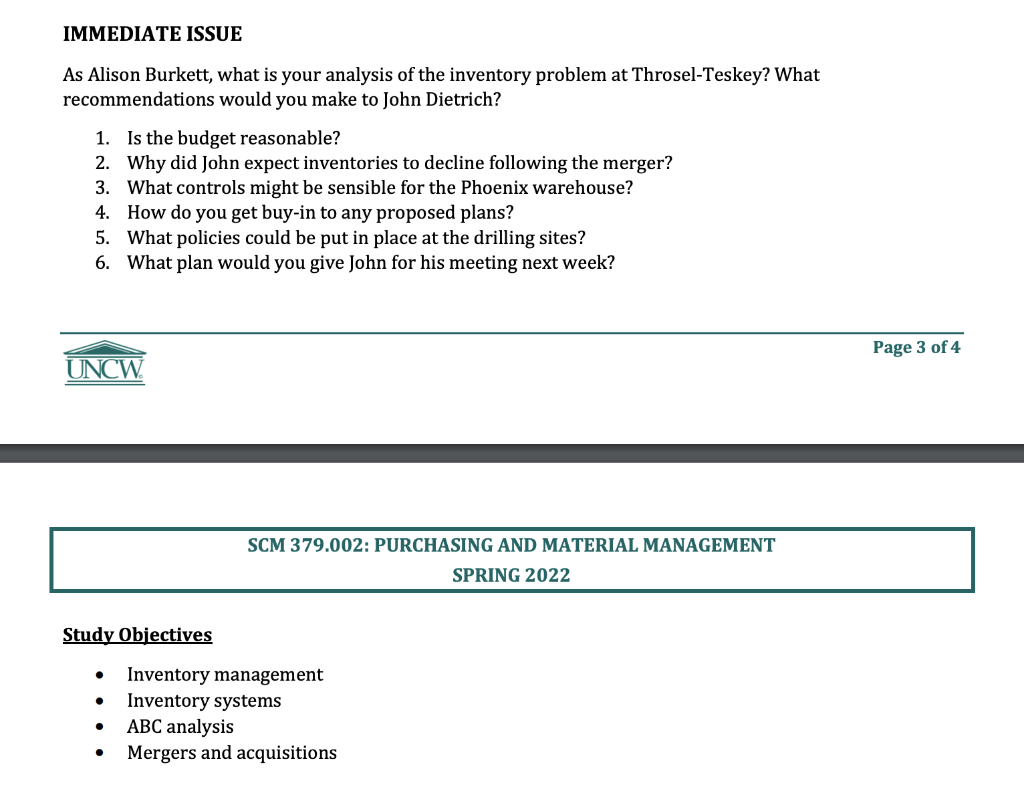

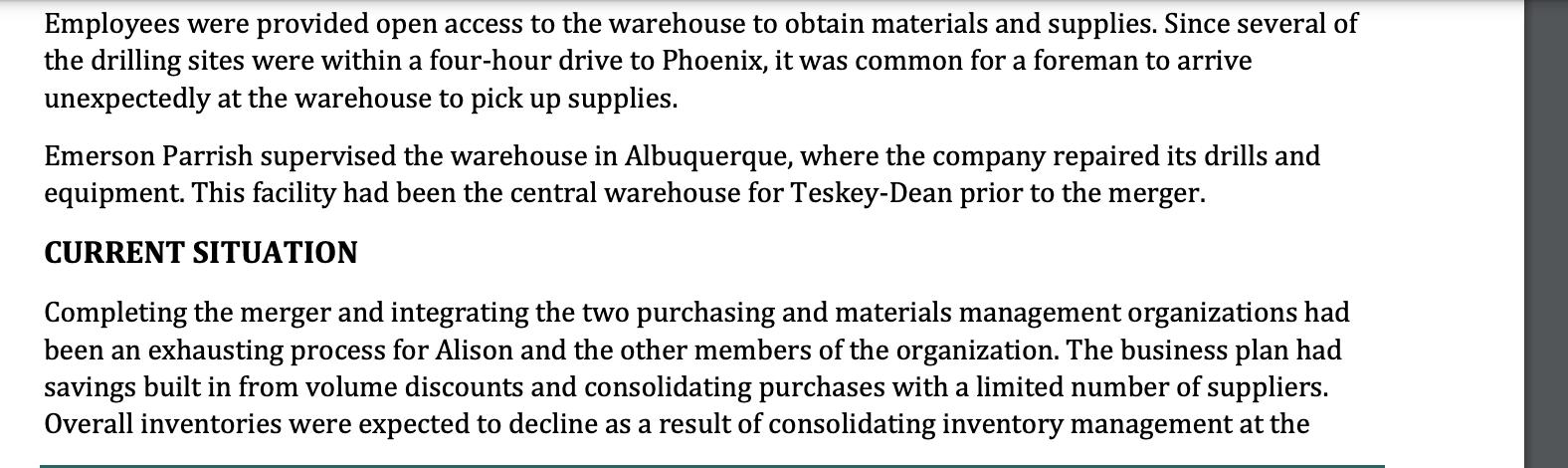

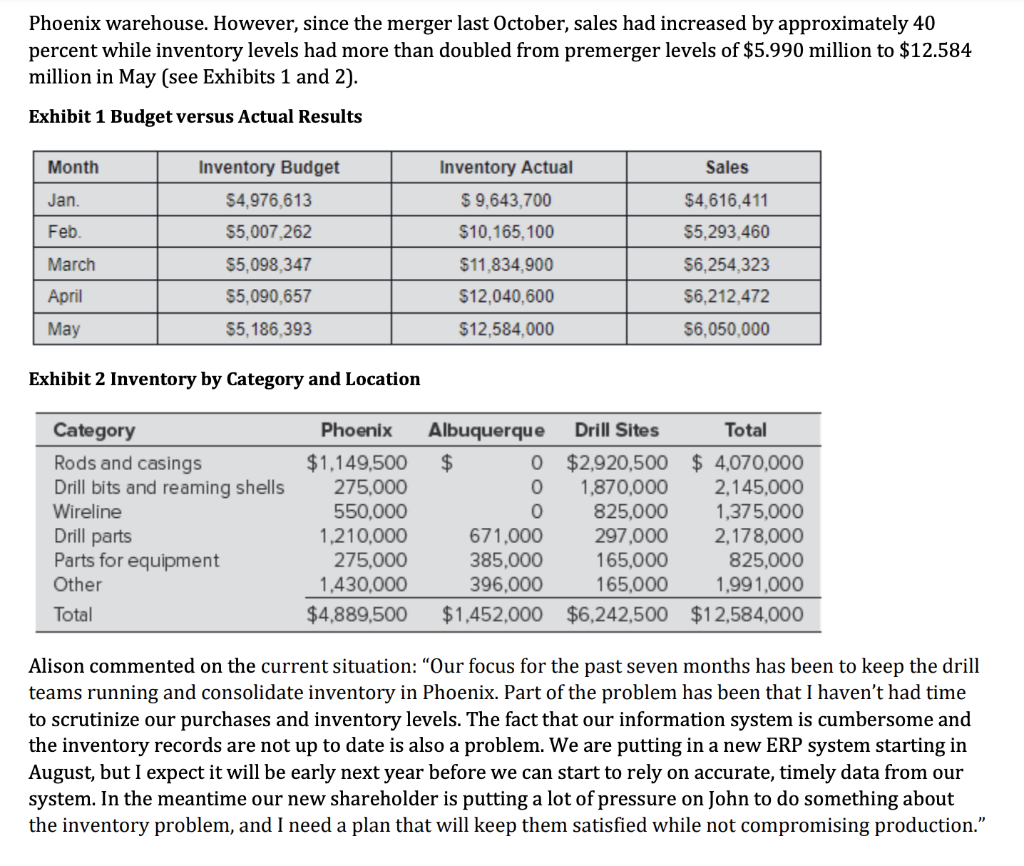

Chapter 8 - Quantity and Inventory Case 8-2: Throsel-Teskey Drilling On Wednesday, June 12, Alison Burkett, purchasing manager at Throsel-Teskey Drilling Inc. (Throsel- Teskey) in Phoenix, Arizona, met with John Dietrich, the company's president. He said: "I am getting pressure from the board to address our inventory variance. It has been more than seven months since the merger, and we are not getting the synergies that we expected from purchasing. I know our sales are slightly higher than we expected, but inventory levels are more than twice what we had forecasted in our budget. Our new shareholder is iratethey expect a 25 percent return on their capital. I need you to come up with a plan that I can share with our board at the meeting here in Phoenix next Thursday. Alison got up from her chair and responded to John, I will get you a report with my recommendations on Monday, so we can review it before the meeting." THROSEL-TESKEY DRILLING Throsel-Teskey was a mining services company that performed diamond drilling for underground and surface exploration. Based in Phoenix, Arizona, the company had more than 600 employees and approximately 145 surface and underground drilling rigs operating at sites in the United States, Canada, Mexico, and South America. The company's customers were top-tier multinational and junior mining companies involved in the exploration and production of copper, zinc, and gold. Approximately 75 percent of the company's drilling rigs operated at sites in the southwestern United States. Diamond drilling was required at each stage of mining operations: exploration, development, and production. Diamond core drilling utilized an annular drill bit with an industrial-grade diamond crown to cut a cylindrical core from solid rock. Core samples were extracted and analyzed to provide the mine operator with information about the mineral deposit. Throsel-Teskey paid its drill teams a base rate and an incentive bonus for achieving production targets. Production levels averaged 825 feet per week for each drill team, but varied substantially depending on conditions. In the previous October, Throsel Drilling Inc. merged with Teskey-Dean Drilling Inc. (Teskey-Dean), which had its head office in Albuquerque, New Mexico. Both companies were approximately the same size with In the previous October, Throsel Drilling Inc. merged with Teskey-Dean Drilling Inc. (Teskey-Dean), which had its head office in Albuquerque, New Mexico. Both companies were approximately the same size with respect to total sales; however, Teskey-Dean specialized in underground drilling while Throsel's focus had been in surface drilling. Jongsma Equity Partners (Jongsma), a Chicago-based private equity firm, which owned Teskey-Dean, led the merger and financing of the transaction. John Dietrich, who had been CEO of Throsel, was appointed the president and CEO of the new company and operations were consolidated at Throsel's facilities located in Phoenix. Although Jongsma controlled Throsel-Teskey, John Dietrich maintained a substantial equity interest in the company. Increases in commodity prices during the past two years had resulted in substantial increases in demand for drilling services as mining companies expanded output. As a result, Throsel-Teskey was operating at full capacity. John commented about the current market for his company's services: Our bottlenecks are equipment and people. However, it is asier for me to buy more drilling rigs than to find qualified drillers. The pay is good, but it is hard work and it takes at least a year to get someone fully trained." PURCHASING AND MATERIALS MANAGEMENT Alison Burkett headed the purchasing department at Throsel-Teskey and was responsible for sourcing and materials management. She had worked for John in a similar role at Throsel Drilling for approximately three years. Reporting to Alison was Ken Jenner, materials manager, and Emerson Parrish, warehouse manager. Alison estimated that Throsel-Teskey purchased $25 to $27 million in goods and services each year from approximately 400 suppliers. Major purchase categoriesrods and casing, drill bits and reaming shells, wireline and drill parts (collectively referred to as drilling supplies)accounted for approximately one- half of the company's total spend. The Phoenix warehouse carried approximately 800 different stock keeping units (SKUs), across a variety of purchase categories, such as drilling supplies, tools, safety supplies, parts and equipment, motors, and hydraulic oil. For example, the company stocked eight different types of rods and five different types of diamond drill bits. At the time of the merger the company purchased the majority of its drilling supplies from three companies. Subsequently, John and Alison negotiated a strategic sourcing agreement with a supplier, also located in Phoenix, who became the primary supplier for drilling supplies in return for a significant price discount. Implementation of the new sourcing agreement started in April, and the transition was expected to last six months. However, because of specific needs for certain equipment and drilling applications, Alison expected that it would not be possible to standardize completely with one supplier. The Phoenix warehouse had been expanded and renovated recently to accommodate the increased volume created by the merger. Shelving, racks, and bins had been added to store inventory. Ken Jenner was responsible for receiving, shipping, and inventory control at the Phoenix warehouse. Since the company's inventory system had not been updated since the merger, he physically reviewed inventory levels in the warehouse each Thursday and provided Alison with a written purchase requisition to replenish stock. In recent months, Alison had noticed that several suppliers were experiencing delivery problems and extending lead times as a direct result of an overall increase in demand for diamond drilling services by mining companies. Shipments to drilling sites from Phoenix were made on a five-day schedule by an outside transportation service company. Site foremen faxed or emailed requests for materials and supplies to Ken two days in advance of the scheduled delivery run to their site. Ken supervised two people whose duties included picking and packing orders for the sites. Employees were provided open access to the warehouse to obtain materials and supplies. Since several of the drilling sites were within a four-hour drive to Phoenix, it was common for a foreman to arrive unexpectedly at the warehouse to pick up supplies. Emerson Parrish supervised the warehouse in Albuquerque, where the company repaired its drills and equipment. This facility had been the central warehouse for Teskey-Dean prior to the merger. CURRENT SITUATION Completing the merger and integrating the two purchasing and materials management organizations had been an exhausting process for Alison and the other members of the organization. The business plan had savings built in from volume discounts and consolidating purchases with a limited number of suppliers. Overall inventories were expected to decline as a result of consolidating inventory management at the Phoenix warehouse. However, since the merger last October, sales had increased by approximately 40 percent while inventory levels had more than doubled from premerger levels of $5.990 million to $12.584 million in May (see Exhibits 1 and 2). Exhibit 1 Budget versus Actual Results Month Sales Jan. Feb Inventory Budget $4,976,613 $5,007,262 $5,098,347 $5,090,657 $5,186,393 Inventory Actual $ 9,643,700 $10,165, 100 $11,834,900 $12,040,600 $12,584,000 March $4,616,411 $5,293,460 $6,254,323 $6,212,472 $6,050,000 April May Exhibit 2 Inventory by Category and Location Category Rods casings Drill bits and reaming shells Wireline Drill parts Parts for equipment Other Total Phoenix $1,149,500 275,000 550.000 1,210,000 275,000 1,430,000 $4,889,500 Albuquerque Drill Sites Total $ $2, 00 $ 4,070,000 0 1,870,000 2,145,000 O 825.000 1,375,000 671.000 297,000 2,178,000 385.000 165,000 825,000 396,000 165,000 1,991,000 $1,452,000 $6,242,500 $12,584,000 Alison commented on the current situation: Our focus for the past seven months has been to keep the drill teams running and consolidate inventory in Phoenix. Part of the problem has been that I haven't had time to scrutinize our purchases and inventory levels. The fact that our information system is cumbersome and the inventory records are not up to date is also a problem. We are putting in a new ERP system starting in August, but I expect it will be early next year before we can start to rely on accurate, timely data from our system. In the meantime our new shareholder is putting a lot of pressure on John to do something about the inventory problem, and I need a plan that will keep them satisfied while not compromising production. IMMEDIATE ISSUE As Alison Burkett, what is your analysis of the inventory problem at Throsel-Teskey? What recommendations would you make to John Dietrich? 1. Is the budget reasonable? 2. Why did John expect inventories to decline following the merger? 3. What controls might be sensible for the Phoenix warehouse? 4. How do you get buy-in to any proposed plans? 5. What policies could be put in place at the drilling sites? 6. What plan would you give John for his meeting next week? Page 3 of 4 UNCW. SCM 379.002: PURCHASING AND MATERIAL MANAGEMENT SPRING 2022 Study Objectives Inventory management Inventory systems ABC analysis Mergers and acquisitions