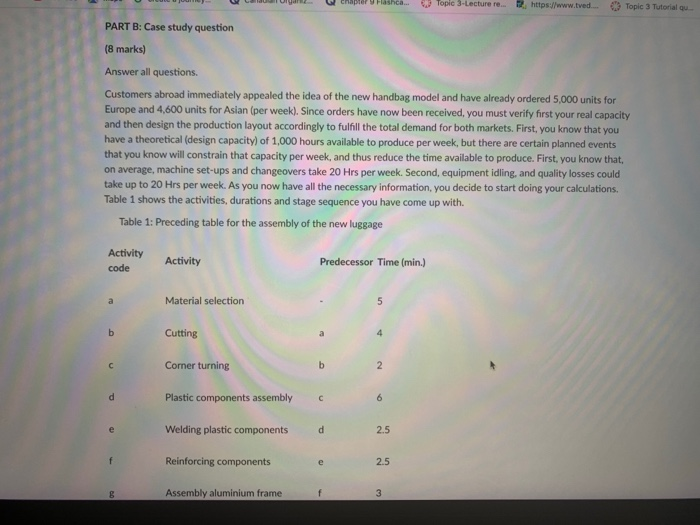

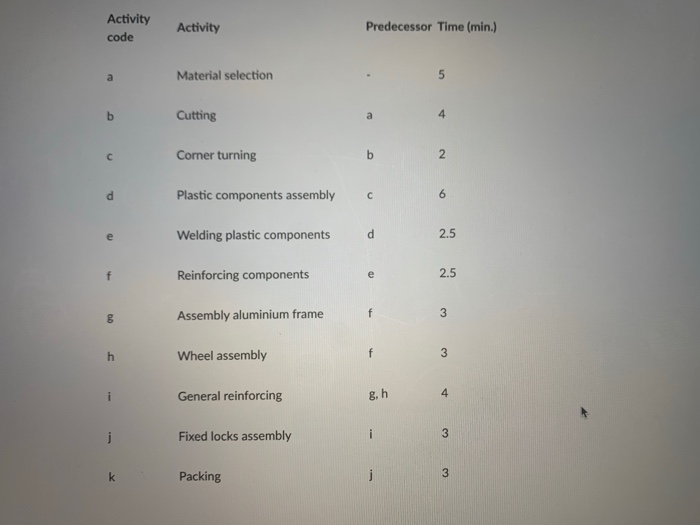

Question: Chapter Flashca. 2 Topic 3-Lecture re... https://www.tved... Topic 3 Tutorial ou PART B: Case study question (8 marks) Answer all questions Customers abroad immediately appealed

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock