Question: Chemical Engineering Process Design (1) Design an absorber for optimum process conditions for the recovery of SO2 from a chimney gas burning high Sulphur from

Chemical Engineering Process Design

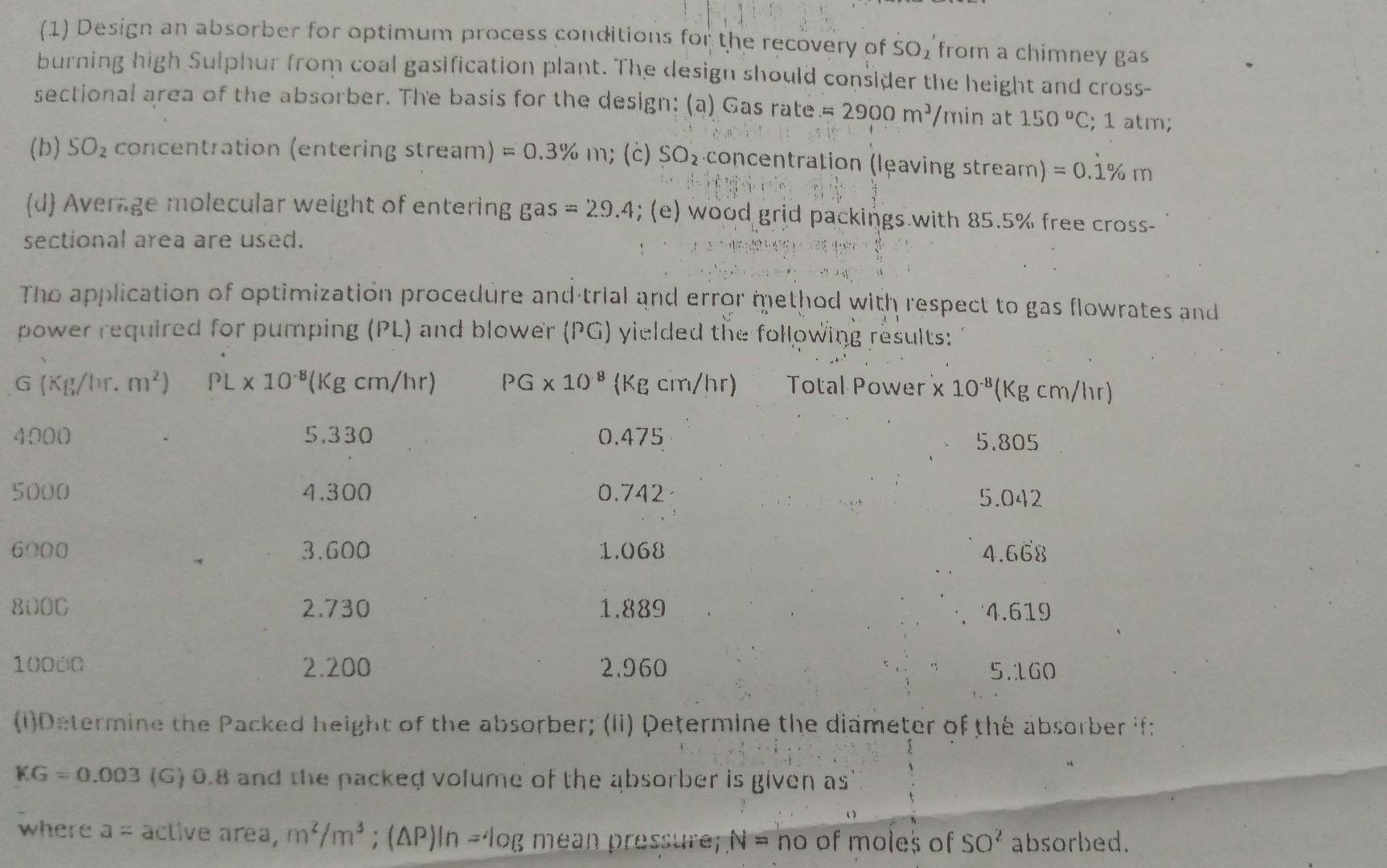

(1) Design an absorber for optimum process conditions for the recovery of SO2 from a chimney gas burning high Sulphur from coal gasification plant. The design should consider the height and crosssectional area of the absorber. The basis for the design: (a) Gas rate =2900m3/min at 150C;1 atm; (b) SO2 concentration (entering stream) =0.3%m; (c) SO2 concentration (leaving stream) =0.1%m (d) Aver.ge molecular weight of entering gas =2.4.4; (e) wood grid packings. with 85.5% free crosssectionat area are used. Tho application of optimization procedure and trial arid error mielhod wirh respect to gas flowrates and power iequired for pumping (PL) and blower (PG) vielded the following results: (i)D:slermine the Packed height of the absorber; (ii) Determine the diameter of the absorber if: KG =0.003(G)0.8 and the packed volume of the absorber is given as where a= aclive area, m2/m3;(P)ln=40gm man presslie, N= no of mole 5 of 502 absorlsed

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts