Question: Coehler makes handheid calculators in two models-basic and protessional Koehier estmated 5721,000 of manutacturing ovehead and 515,000 machine hours for the year. The basic mosel

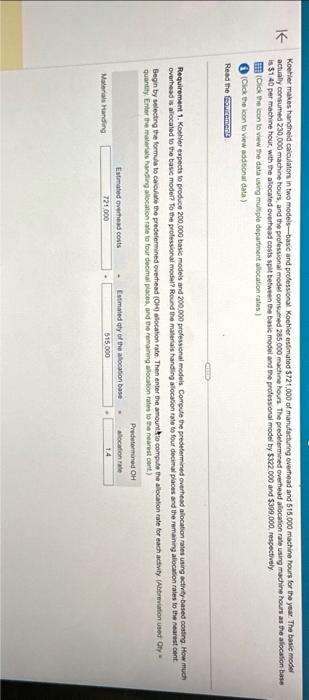

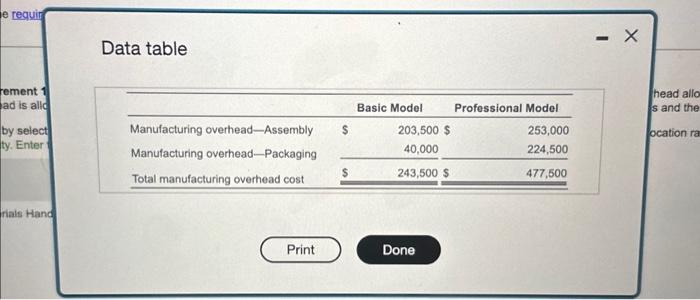

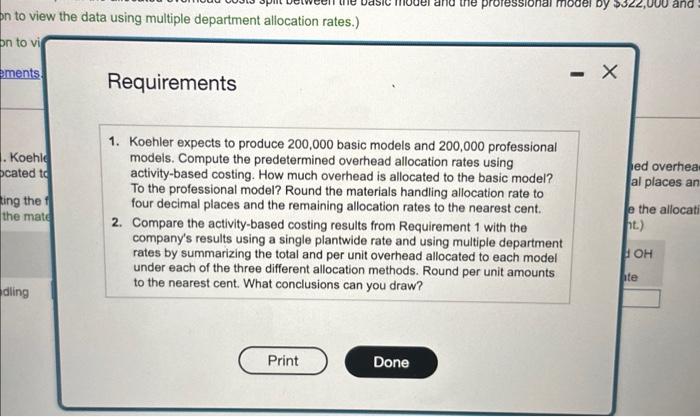

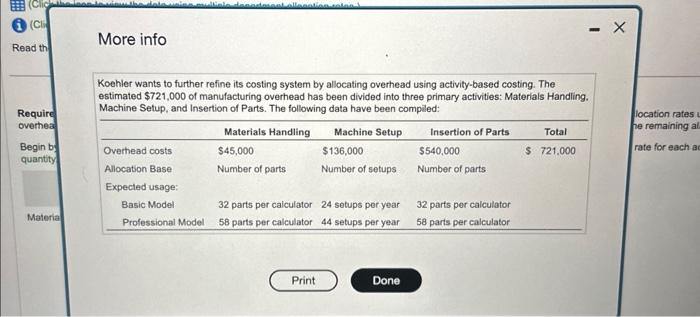

Coehler makes handheid calculators in two models-basic and protessional Koehier estmated 5721,000 of manutacturing ovehead and 515,000 machine hours for the year. The basic mosel actually consumed 230,000 machine hours, and the professional model consumed 285,000 machine hours. The predetermined overhead alocason rate using machine hours as the alocation base s $140 per machine hour, with the alocated overtead costs spit betwet Ese basic model and be proflessional model by $122,000 and $399,000, respectively. (Cick the icon to view the data using multple department allocation rates) (Clck the icon to view addeonal data) Read the Requirement 1. Koehier expects to produce 200,000 basic models and 200,000 protessional models compute the predetermintes overhesd alocabion rales using activily-based costrng. How much quantity. Enter the materiass handing albcation rafe fo four decimal places, and the remaining alocabon rates to the nearest cert.) Data table view the data using multiple department allocation rates.) Requirements 1. Koehler expects to produce 200,000 basic models and 200,000 professional modeis. Compute the predetermined overhead allocation rates using activity-based costing. How much overhead is allocated to the basic model? To the professional model? Round the materials handling allocation rate to four decimal places and the remaining allocation rates to the nearest cent. 2. Compare the activity-based costing results from Requirement 1 with the company's results using a single plantwide rate and using multiple department rates by summarizing the total and per unit overhead allocated to each model under each of the three different allocation methods. Round per unit amounts to the nearest cent. What conclusions can you draw? More info Koehler wants to further refine its costing system by allocating overhead using activity-based costing. The estimated $721,000 of manufacturing overhead has been divided into three primary activities: Materials Handling. Machine Setup, and Insertion of Parts. The following data have been compiled

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts