Question: Complete the level production plan, using the following information. The only costs you need to consider here are layoff, hiring, and inventory costs. If you

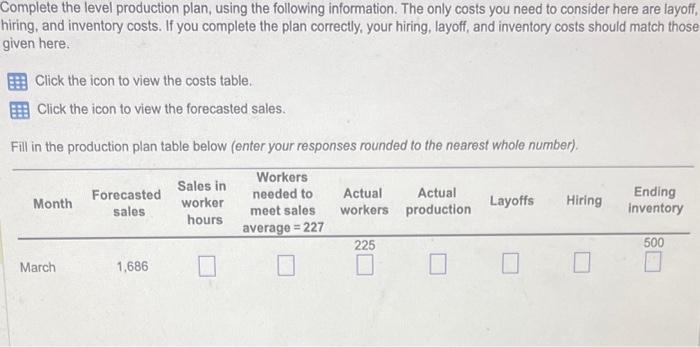

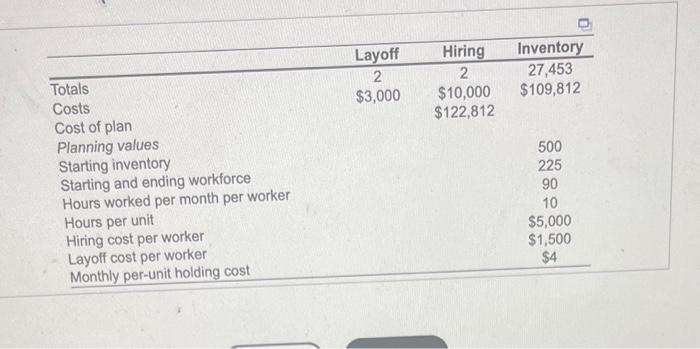

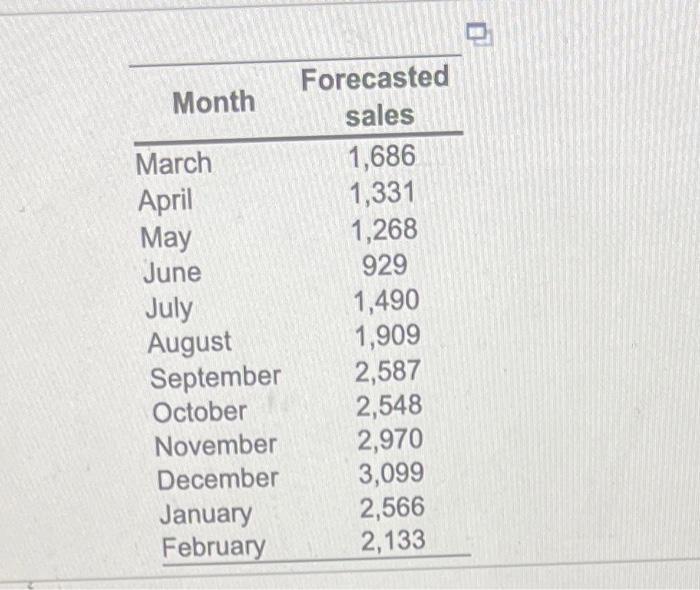

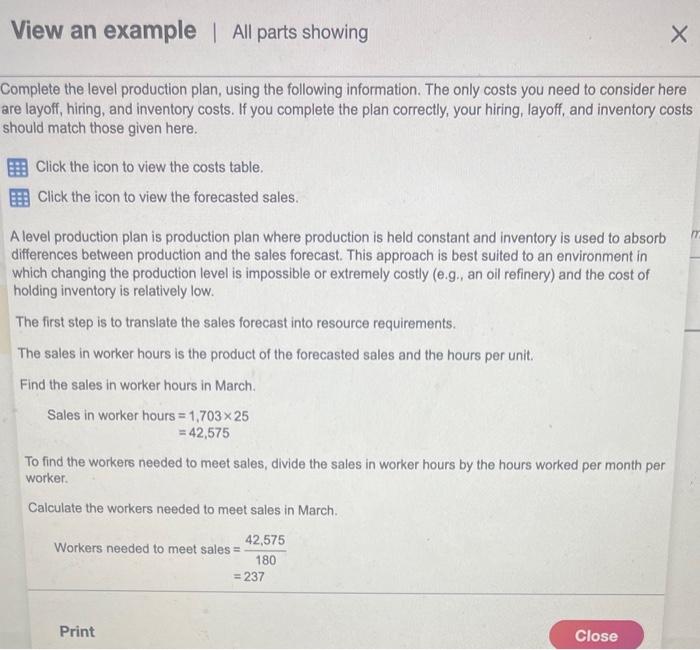

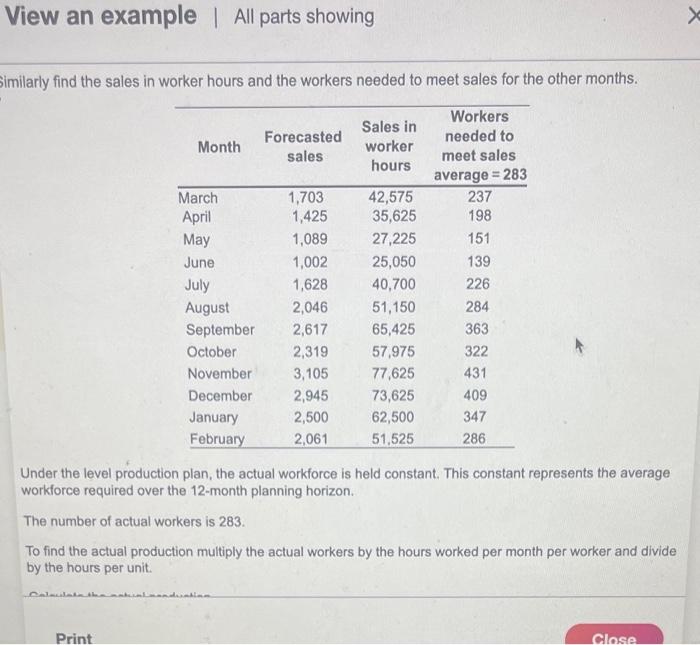

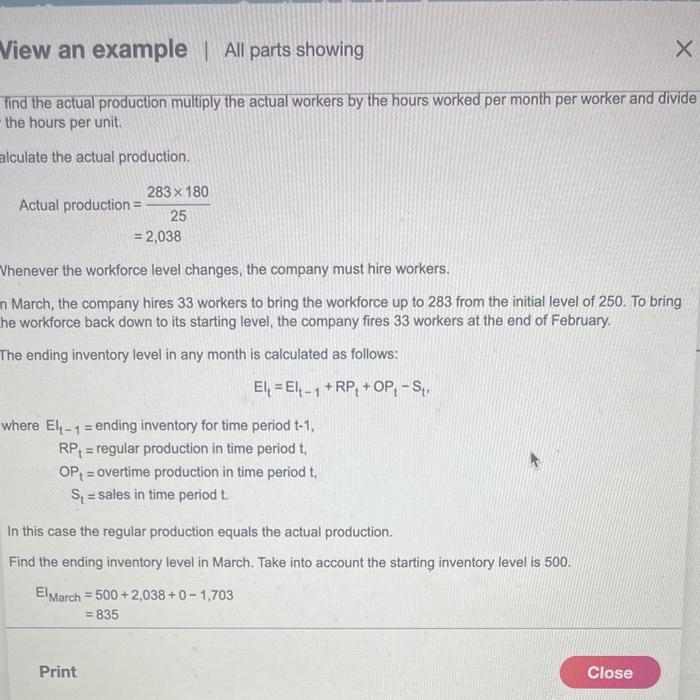

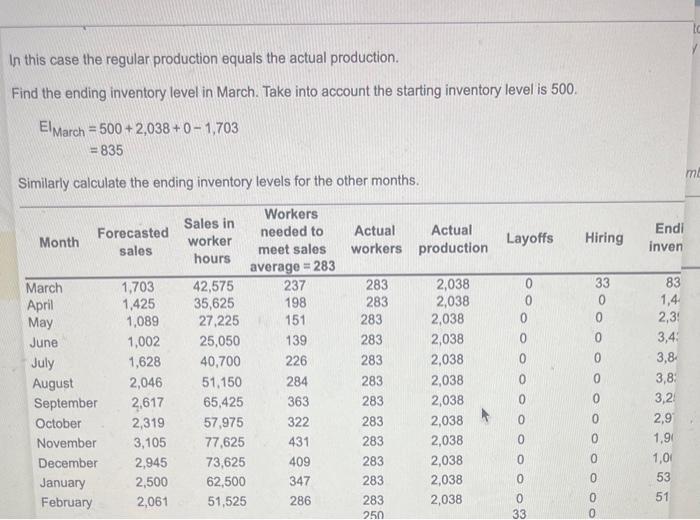

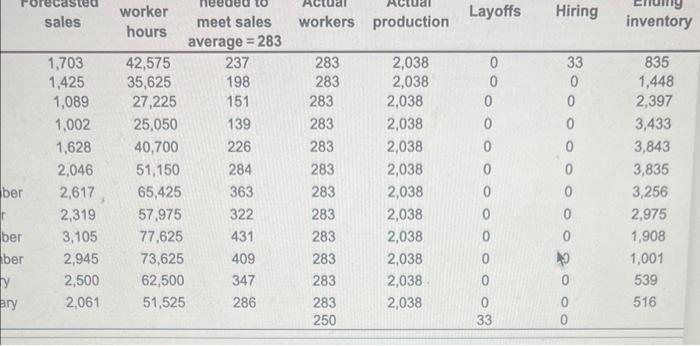

Complete the level production plan, using the following information. The only costs you need to consider here are layoff, hiring, and inventory costs. If you complete the plan correctly, your hiring, layoff, and inventory costs should match those given here. Click the icon to view the costs table. Click the icon to view the forecasted sales. Fill in the production plan table below (enter your responses rounded to the nearest whole number). \begin{tabular}{lccc} & & & \\ & Layoff & Hiring & Inventory \\ \hline Totals & 2 & 2 & 27,453 \\ Costs & $3,000 & $10,000 & $109,812 \\ Cost of plan & & $122,812 & \\ Planning values & & \\ Starting inventory & & 500 \\ Starting and ending workforce & & 225 \\ Hours worked per month per worker & & 90 \\ Hours per unit & & 10 \\ Hiring cost per worker & & $1,000 \\ Layoff cost per worker & & $4 \\ Monthly per-unit holding cost & & \\ \hline \end{tabular} \begin{tabular}{lc} \hline Month & Forecastedsales \\ \hline March & 1,686 \\ April & 1,331 \\ May & 1,268 \\ June & 929 \\ July & 1,490 \\ August & 1,909 \\ September & 2,587 \\ October & 2,548 \\ November & 2,970 \\ December & 3,099 \\ January & 2,566 \\ February & 2,133 \\ \hline \end{tabular} Complete the level production plan, using the following information. The only costs you need to consider here are layoff, hiring, and inventory costs. If you complete the plan correctly, your hiring, layoff, and inventory costs should match those given here. Click the icon to view the costs table. Click the icon to view the forecasted sales. A level production plan is production plan where production is held constant and inventory is used to absorb differences between production and the sales forecast. This approach is best suited to an environment in which changing the production level is impossible or extremely costly (e.g., an oil refinery) and the cost of holding inventory is relatively low. The first step is to translate the sales forecast into resource requirements. The sales in worker hours is the product of the forecasted sales and the hours per unit. Find the sales in worker hours in March. Salesinworkerhours=1,70325=42,575 To find the workers needed to meet sales, divide the sales in worker hours by the hours worked per month per worker. Calculate the workers needed to meet sales in March. Workersneededtomeetsales=18042,575=237 imilarly find the sales in worker hours and the workers needed to meet sales for the other months. Under the level production plan, the actual workforce is held constant. This constant represents the average workforce required over the 12-month planning horizon. The number of actual workers is 283 . To find the actual production multiply the actual workers by the hours worked per month per worker and divide by the hours per unit. find the actual production multiply the actual workers by the hours worked per month per worker and divide the hours per unit. alculate the actual production. Actualproduction=25283180=2,038 Vhenever the workforce level changes, the company must hire workers. n March, the company hires 33 workers to bring the workforce up to 283 from the initial level of 250 . To bring he workforce back down to its starting level, the company fires 33 workers at the end of February. The ending inventory level in any month is calculated as follows: Elt=Elt1+RPt+OPtSt where Elt1 = ending inventory for time period t1, RPt= regular production in time period t, OOPt= overtime production in time period t, St= sales in time period t. In this case the regular production equals the actual production. Find the ending inventory level in March. Take into account the starting inventory level is 500 . ElMarch=500+2,038+01,703 In this case the regular production equals the actual production. Find the ending inventory level in March. Take into account the starting inventory level is 500 . EIMarch=500+2,038+01,703=835 Similarly calculate the ending inventory levels for the other months. Complete the level production plan, using the following information. The only costs you need to consider here are layoff, hiring, and inventory costs. If you complete the plan correctly, your hiring, layoff, and inventory costs should match those given here. Click the icon to view the costs table. Click the icon to view the forecasted sales. Fill in the production plan table below (enter your responses rounded to the nearest whole number). \begin{tabular}{lccc} & & & \\ & Layoff & Hiring & Inventory \\ \hline Totals & 2 & 2 & 27,453 \\ Costs & $3,000 & $10,000 & $109,812 \\ Cost of plan & & $122,812 & \\ Planning values & & \\ Starting inventory & & 500 \\ Starting and ending workforce & & 225 \\ Hours worked per month per worker & & 90 \\ Hours per unit & & 10 \\ Hiring cost per worker & & $1,000 \\ Layoff cost per worker & & $4 \\ Monthly per-unit holding cost & & \\ \hline \end{tabular} \begin{tabular}{lc} \hline Month & Forecastedsales \\ \hline March & 1,686 \\ April & 1,331 \\ May & 1,268 \\ June & 929 \\ July & 1,490 \\ August & 1,909 \\ September & 2,587 \\ October & 2,548 \\ November & 2,970 \\ December & 3,099 \\ January & 2,566 \\ February & 2,133 \\ \hline \end{tabular} Complete the level production plan, using the following information. The only costs you need to consider here are layoff, hiring, and inventory costs. If you complete the plan correctly, your hiring, layoff, and inventory costs should match those given here. Click the icon to view the costs table. Click the icon to view the forecasted sales. A level production plan is production plan where production is held constant and inventory is used to absorb differences between production and the sales forecast. This approach is best suited to an environment in which changing the production level is impossible or extremely costly (e.g., an oil refinery) and the cost of holding inventory is relatively low. The first step is to translate the sales forecast into resource requirements. The sales in worker hours is the product of the forecasted sales and the hours per unit. Find the sales in worker hours in March. Salesinworkerhours=1,70325=42,575 To find the workers needed to meet sales, divide the sales in worker hours by the hours worked per month per worker. Calculate the workers needed to meet sales in March. Workersneededtomeetsales=18042,575=237 imilarly find the sales in worker hours and the workers needed to meet sales for the other months. Under the level production plan, the actual workforce is held constant. This constant represents the average workforce required over the 12-month planning horizon. The number of actual workers is 283 . To find the actual production multiply the actual workers by the hours worked per month per worker and divide by the hours per unit. find the actual production multiply the actual workers by the hours worked per month per worker and divide the hours per unit. alculate the actual production. Actualproduction=25283180=2,038 Vhenever the workforce level changes, the company must hire workers. n March, the company hires 33 workers to bring the workforce up to 283 from the initial level of 250 . To bring he workforce back down to its starting level, the company fires 33 workers at the end of February. The ending inventory level in any month is calculated as follows: Elt=Elt1+RPt+OPtSt where Elt1 = ending inventory for time period t1, RPt= regular production in time period t, OOPt= overtime production in time period t, St= sales in time period t. In this case the regular production equals the actual production. Find the ending inventory level in March. Take into account the starting inventory level is 500 . ElMarch=500+2,038+01,703 In this case the regular production equals the actual production. Find the ending inventory level in March. Take into account the starting inventory level is 500 . EIMarch=500+2,038+01,703=835 Similarly calculate the ending inventory levels for the other months

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts