Question: Conduct a present worth analysis. a) Consider that the replacements will be for identical units. b) The salvage value of the equipment corresponds to the

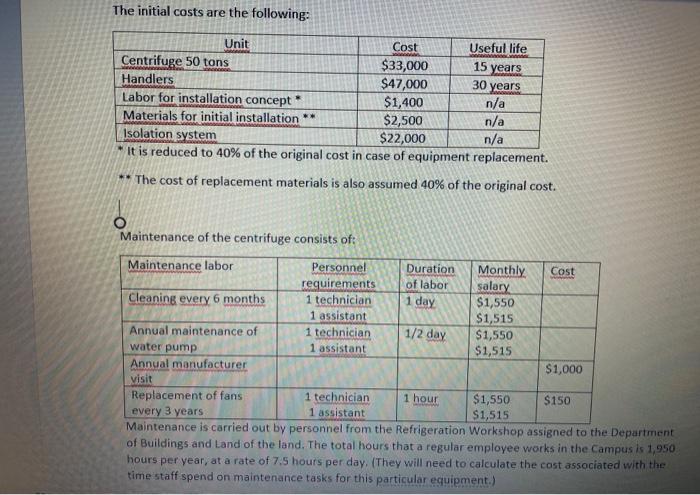

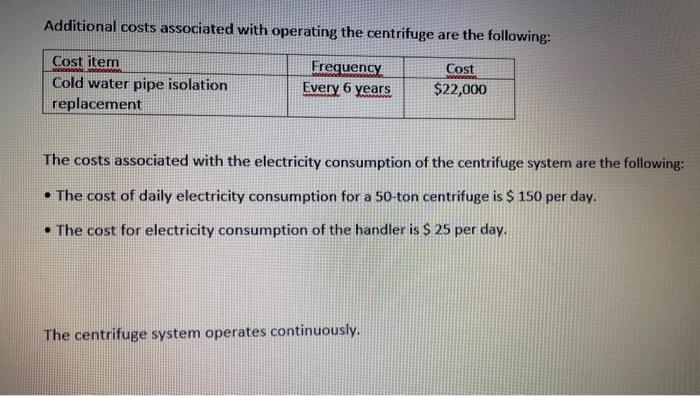

The initial costs are the following: 15 years 30 years Unit Cost Useful life Centrifuge 50 tons $33,000 Handlers $47,000 Labor for installation concept $1,400 n/a Materials for initial installation ** $2,500 n/a Isolation system $22,000 n/a it is reduced to 40% of the original cost in case of equipment replacement. ** The cost of replacement materials is also assumed 40% of the original cost. Cost O Maintenance of the centrifuge consists of: Maintenance labor Personnel Duration Monthly requirements of labor salary Cleaning every 6 months 1 technician 1 day $1,550 1 assistant $1,515 Annual maintenance of 1 technician 1/2 day $1,550 water pump 1 assistant $1,515 Annual manufacturer $1,000 visit Replacement of fans 1 technician 1 hour $1,550 $150 every 3 years 1 assistant $1,515 Maintenance is carried out by personnel from the Refrigeration Workshop assigned to the Department of Buildings and Land of the land. The total hours that a regular employee works in the Campus is 1,950 hours per year, at a rate of 7.5 hours per day. (They will need to calculate the cost associated with the time staff spend on maintenance tasks for this particular equipment.) Additional costs associated with operating the centrifuge are the following: Cost item Cold water pipe isolation replacement Frequency Every 6 years Cost $22,000 The costs associated with the electricity consumption of the centrifuge system are the following: The cost of daily electricity consumption for a 50-ton centrifuge is $ 150 per day. The cost for electricity consumption of the handler is $ 25 per day. The centrifuge system operates continuously. The initial costs are the following: 15 years 30 years Unit Cost Useful life Centrifuge 50 tons $33,000 Handlers $47,000 Labor for installation concept $1,400 n/a Materials for initial installation ** $2,500 n/a Isolation system $22,000 n/a it is reduced to 40% of the original cost in case of equipment replacement. ** The cost of replacement materials is also assumed 40% of the original cost. Cost O Maintenance of the centrifuge consists of: Maintenance labor Personnel Duration Monthly requirements of labor salary Cleaning every 6 months 1 technician 1 day $1,550 1 assistant $1,515 Annual maintenance of 1 technician 1/2 day $1,550 water pump 1 assistant $1,515 Annual manufacturer $1,000 visit Replacement of fans 1 technician 1 hour $1,550 $150 every 3 years 1 assistant $1,515 Maintenance is carried out by personnel from the Refrigeration Workshop assigned to the Department of Buildings and Land of the land. The total hours that a regular employee works in the Campus is 1,950 hours per year, at a rate of 7.5 hours per day. (They will need to calculate the cost associated with the time staff spend on maintenance tasks for this particular equipment.) Additional costs associated with operating the centrifuge are the following: Cost item Cold water pipe isolation replacement Frequency Every 6 years Cost $22,000 The costs associated with the electricity consumption of the centrifuge system are the following: The cost of daily electricity consumption for a 50-ton centrifuge is $ 150 per day. The cost for electricity consumption of the handler is $ 25 per day. The centrifuge system operates continuously

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts