Question: CONFIDENTIAL 2 AC / NOV 2 0 2 4 / MAF 2 0 1 QUESTION Fresh Organic Manufacturer is a producer of organic juice concentrates.

CONFIDENTIAL

ACNOV MAF

QUESTION

Fresh Organic Manufacturer is a producer of organic juice concentrates. It supplies juice concentrates in bulk to beverage companies that produce retail products. Due to its concentrated nature, the organic juice concentrate is frequently utilised as a natural sweetening agent. It adds sweetness to products without requiring excessive amounts of sugar or artificial sweeteners. It makes a healthier alternative for individuals seeking to lower their sugar consumption while enjoying a sweet flavour.

The company produces two juice concentrates, CitrusBliss and BerryBurst. They undergo two sequential processes, starting with extraction and followed by the concentration process. To assure product quality, every process is thoroughly inspected after completion before moving to the next phase.

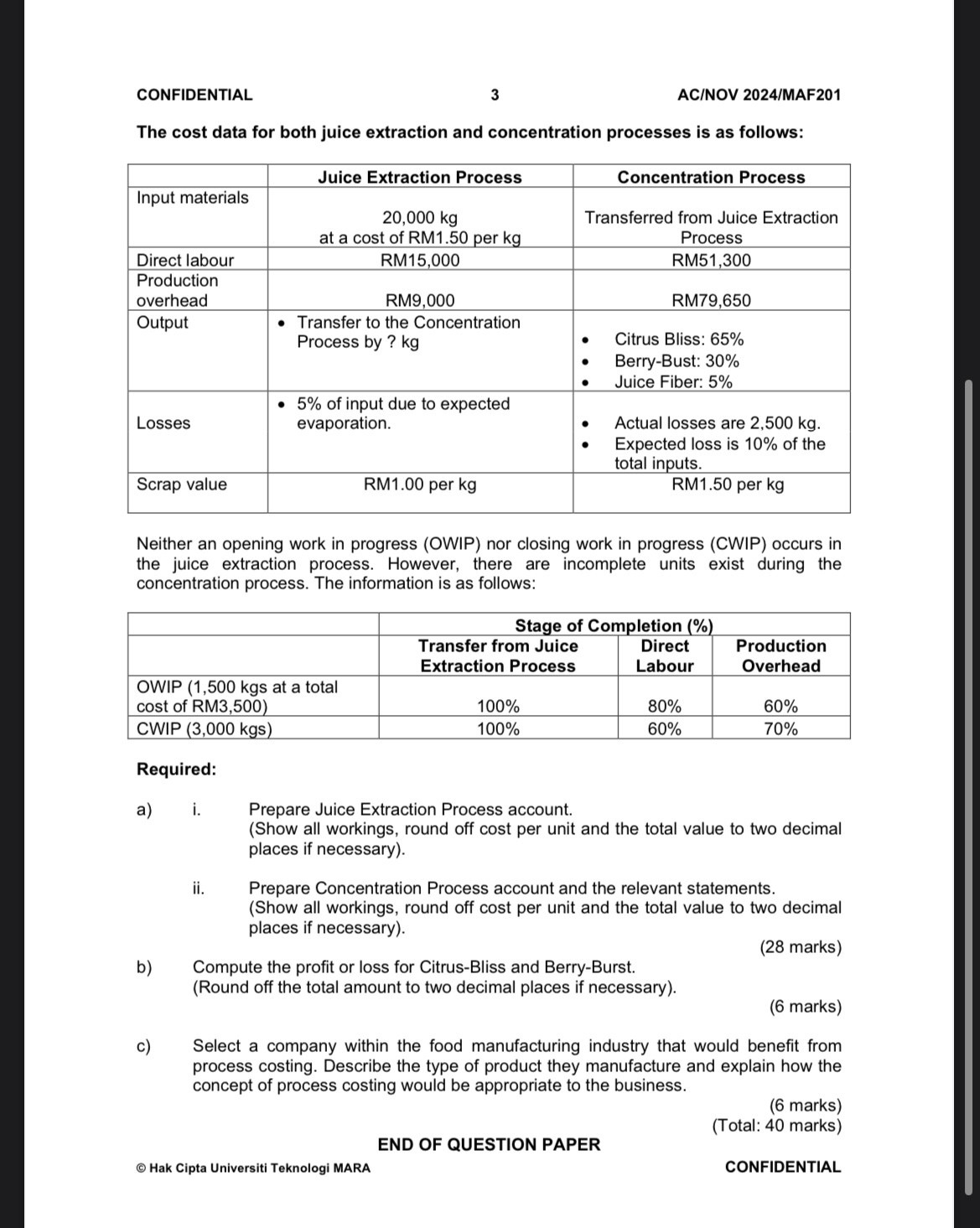

The following information relates to the details of both processes.

Juice Extraction Process

The extraction process involves obtaining juice by removing the skin, seeds, and any unwanted particles from the fruit. The fruit components are pressed and the juice is separated from the pulp, leaving a concentrate of the fruit juice.

Typically, at the end of this process, of the input results in a byproduct. With additional processing of RM per kilogram kg this byproduct is converted into Fruit Pulp, which is used in animal feed. The selling price of Fruit Pulp is RM per kg The net realisable value of the Fruit Pulp is utilised to lower the production costs associated with the juice extraction process. No abnormal gains or abnormal losses were identified in this process.

Concentration Process

This process involves removing water from the juice, yielding a more concentrated product. This is commonly achieved through evaporation or vacuum techniques. The purpose of the concentration process is to reduce the volume of the juice while preserving its natural flavour. The juice concentrate is heated and reduced, which separates the liquid into two distinct products: CitrusBliss and BerryBurst.

CitrusBliss will incur an additional processing cost of RM per kg whereas BerryBurst will not have any additional processing costs. CitrusBliss is sold for RM per kg while BerryBurst is sold for RM per kg The joint costs are allocated based on the net realisable value method.

Additionally, a byproduct known as Juice Fiber is created during the extraction of CitrusBliss and BerryBurst from the juice concentrate. Juice Fiber can be sold for RM per kg

c Hak Cipta Universiti Teknologi MARA

CONFIDENTIAL

CONFIDENTIAL

ACNOV MAF

The cost data for both juice extraction and concentration processes is as follows:

tableJuice Extraction Process,Concentration ProcessInput materials,table kgat a cost of RM per kgTransferred from Juice Extraction ProcessDirect labour,RMRMProduction overhead,RMRMOutput Transfer to the Concentration Process by kgtable Citrus Bliss: BerryBust:

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock