Question: connect Problem 17-1A Comparing costs using ABC with the plantwide overhead rate A1 A2 P1 p3 The following data are for the two products produced

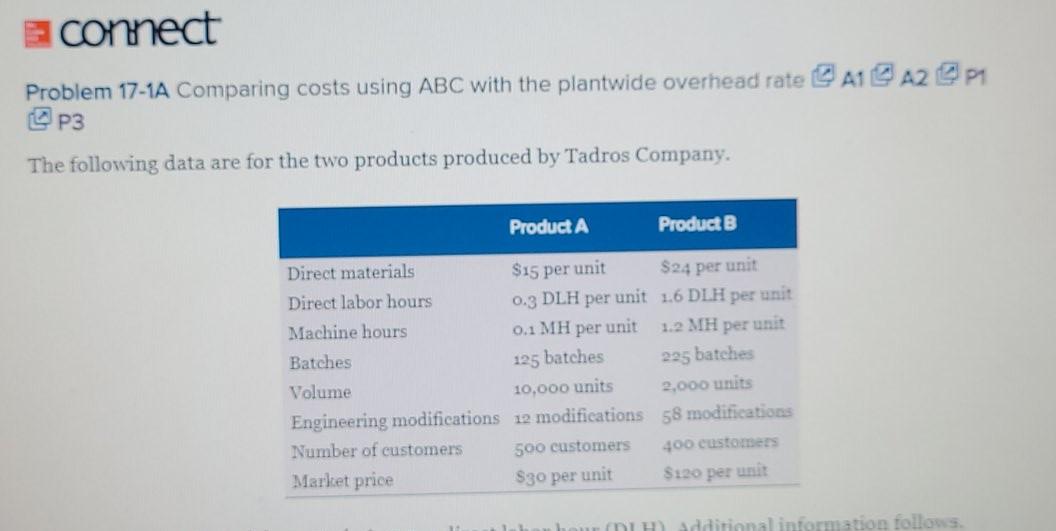

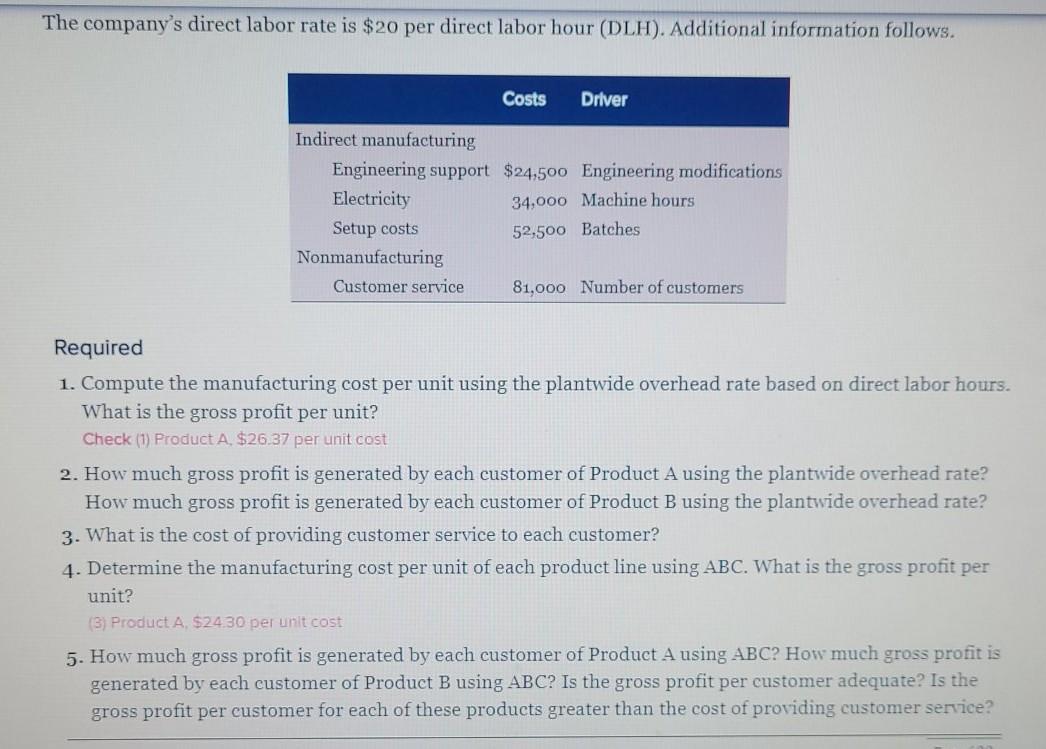

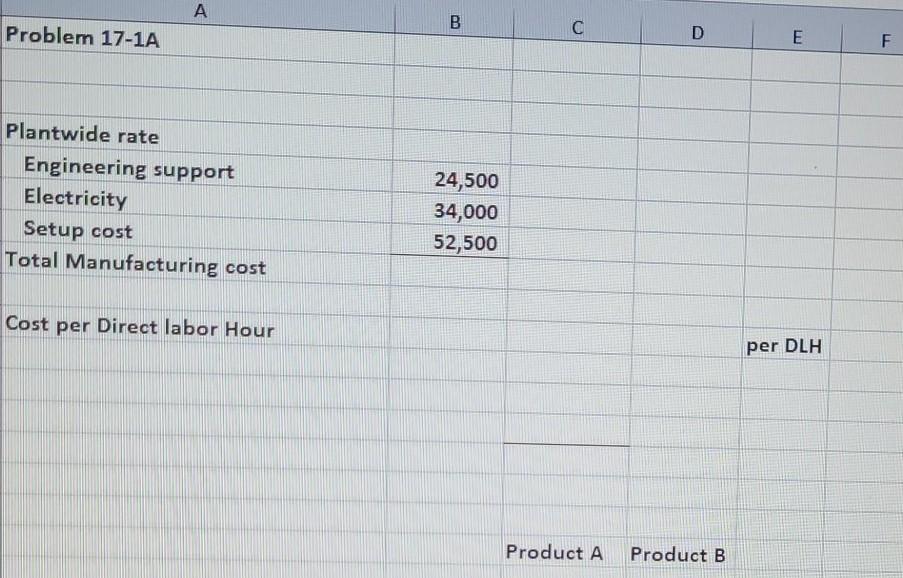

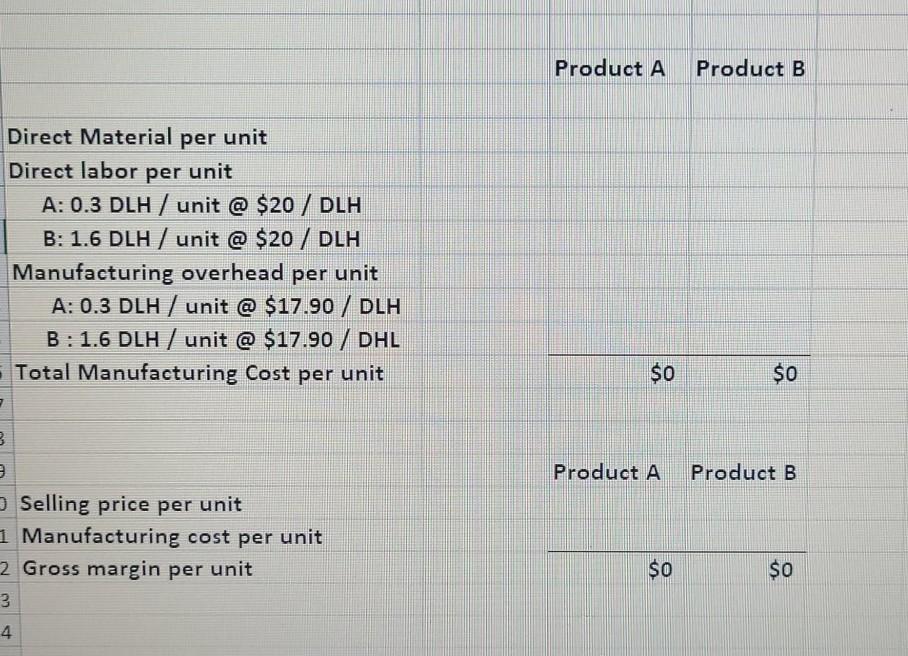

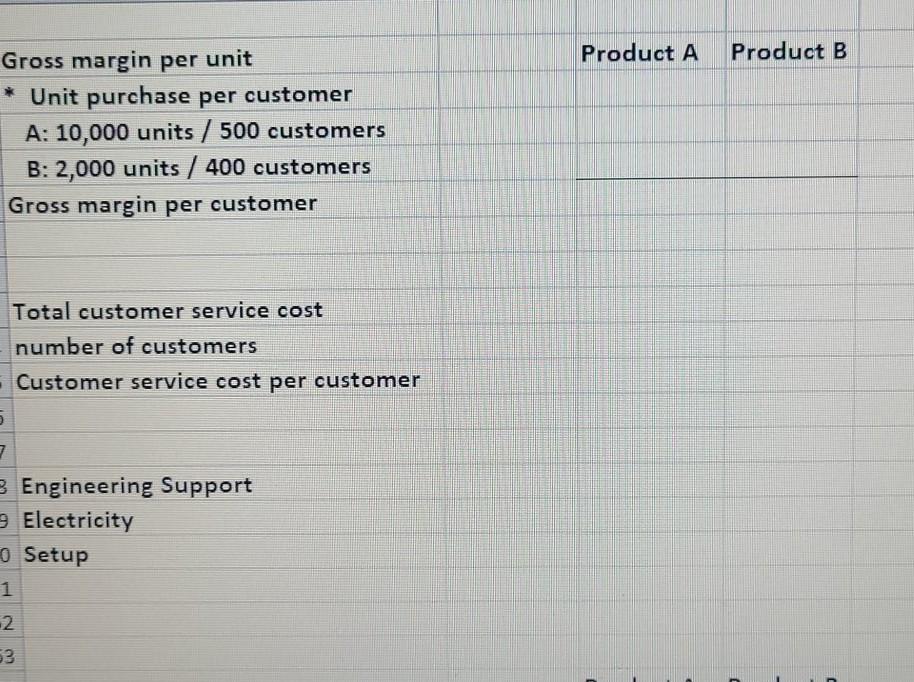

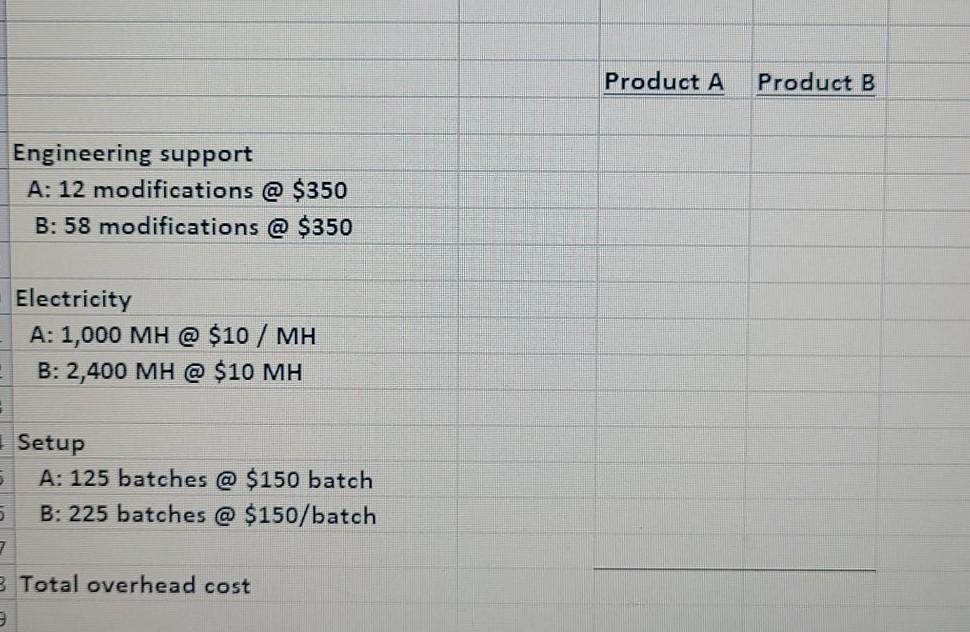

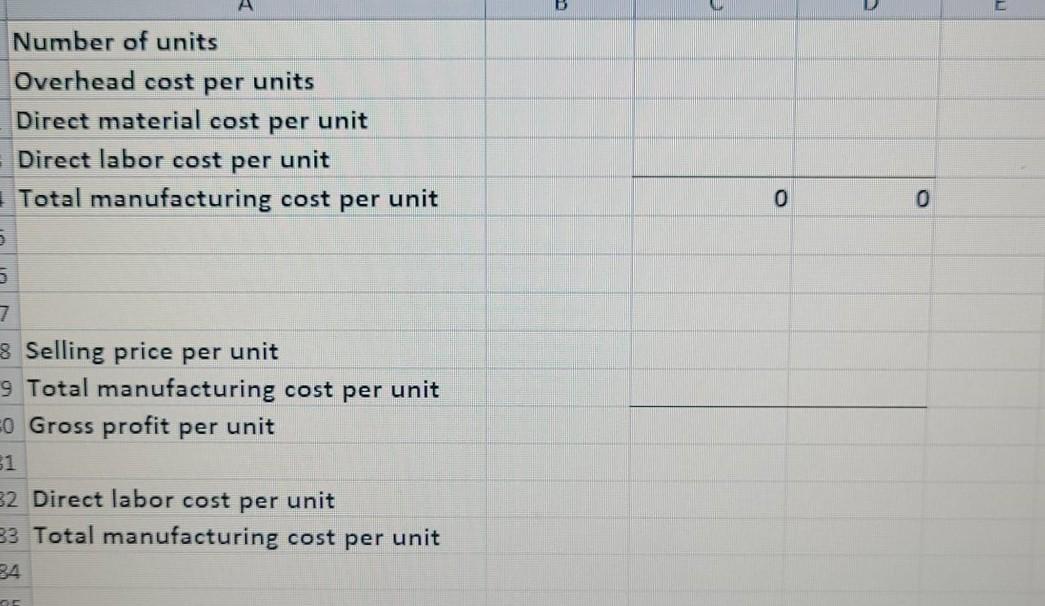

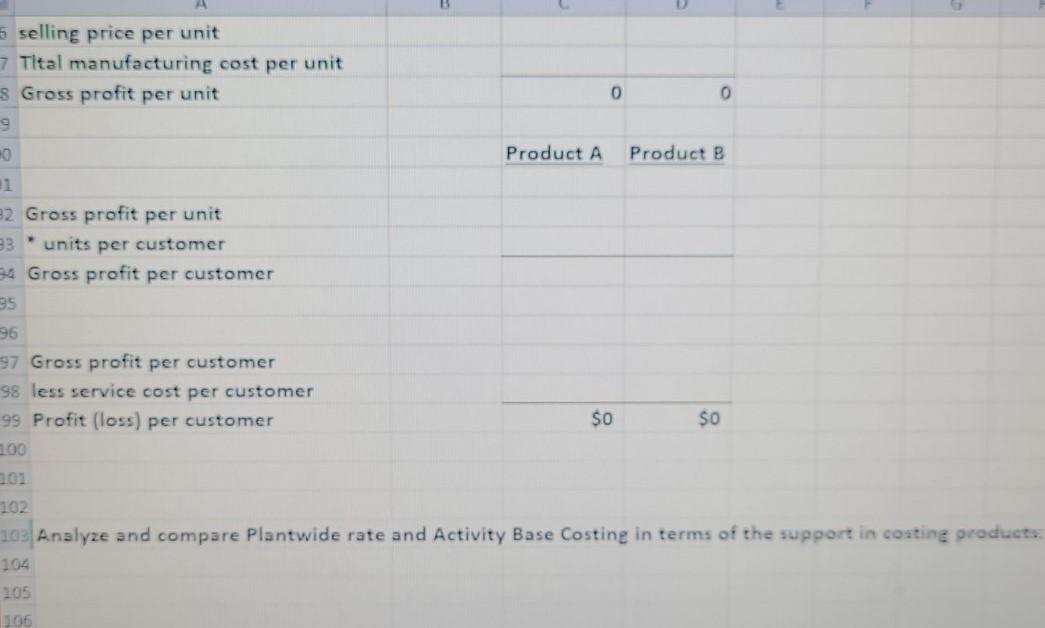

connect Problem 17-1A Comparing costs using ABC with the plantwide overhead rate A1 A2 P1 p3 The following data are for the two products produced by Tadros Company. Product A Product B Direct materials $15 per unit $24 per unit Direct labor hours 0.3 DLH per unit 16 DLH per unit Machine hours 0.1 MH per unit 1.2 MH per unit Batches 125 batches 225 batches Volume 10,000 units 2,000 units Engineering modifications 12 modifications 58 modifications Number of customers 500 customers 400 customers Market price Szo per unit S120 per unit hour additional information follows. The company's direct labor rate is $20 per direct labor hour (DLH). Additional information follows. Costs Driver Indirect manufacturing Engineering support $24,500 Engineering modifications Electricity 34,000 Machine hours Setup costs 52,500 Batches Nonmanufacturing Customer service 81,000 Number of customers Required 1. Compute the manufacturing cost per unit using the plantwide overhead rate based on direct labor hours. What is the gross profit per unit? Check (1) Product A $26.37 per unit cost 2. How much gross profit is generated by each customer of Product A using the plantwide overhead rate? How much gross profit is generated by each customer of Product B using the plantwide overhead rate? 3. What is the cost of providing customer service to each customer? 4. Determine the manufacturing cost per unit of each product line using ABC. What is the gross profit per unit? (3) Product A, $24.30 per unit cost 5. How much gross profit is generated by each customer of Product A using ABC? How much gross profit is generated by each customer of Product B using ABC? Is the gross profit per customer adequate? Is the gross profit per customer for each of these products greater than the cost of providing customer service? B Problem 17-1A D E F Plantwide rate Engineering support Electricity Setup cost Total Manufacturing cost 24,500 34,000 52,500 Cost per Direct labor Hour per DLH Product A Product B Product A Product B Direct Material per unit Direct labor per unit A: 0.3 DLH / unit @ $20 / DLH B: 1.6 DLH / unit @ $20 / DLH Manufacturing overhead per unit A: 0.3 DLH / unit @ $17.90 / DLH B: 1.6 DLH / unit @ $17.90 / DHL Total Manufacturing Cost per unit - $o SO 3 Product A Product B 2 Selling price per unit 1 Manufacturing cost per unit 2 Gross margin per unit 3 $0 $0 4 Product A Product B Gross margin per unit * Unit purchase per customer A: 10,000 units / 500 customers B: 2,000 units / 400 customers Gross margin per customer Total customer service cost number of customers Customer service cost per customer 5 7 3 Engineering Support 9 Electricity 0 Setup 1 2 53 3 Product A Product B Engineering support A: 12 modifications @ $350 B: 58 modifications @ $350 Electricity A: 1,000 MH @ $10 / MH B: 2,400 MH @ $10 MH Setup A: 125 batches @ $150 batch B: 225 batches @ $150/batch 7 3 Total overhead cost 3 Number of units Overhead cost per units Direct material cost per unit Direct labor cost per unit Total manufacturing cost per unit 0 0 5 7 8 Selling price per unit 9 Total manufacturing cost per unit Eo Gross profit per unit 51 B2 Direct labor cost per unit 33 Total manufacturing cost per unit 34 6 selling price per unit 7 Tltal manufacturing cost per unit 8 Gross profit per unit 0 0 9 0 Product A Product B 21 22 Gross profit per unit 23 units per customer 34 Gross profit per customer 95 96 97 Gross profit per customer 98 less service cost per customer 99 Profit (loss) per customer SO So 100 101 102 103 Analyze and compare Plantwide rate and Activity Base Costing in terms of the support in costing products: 104 105 106

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts