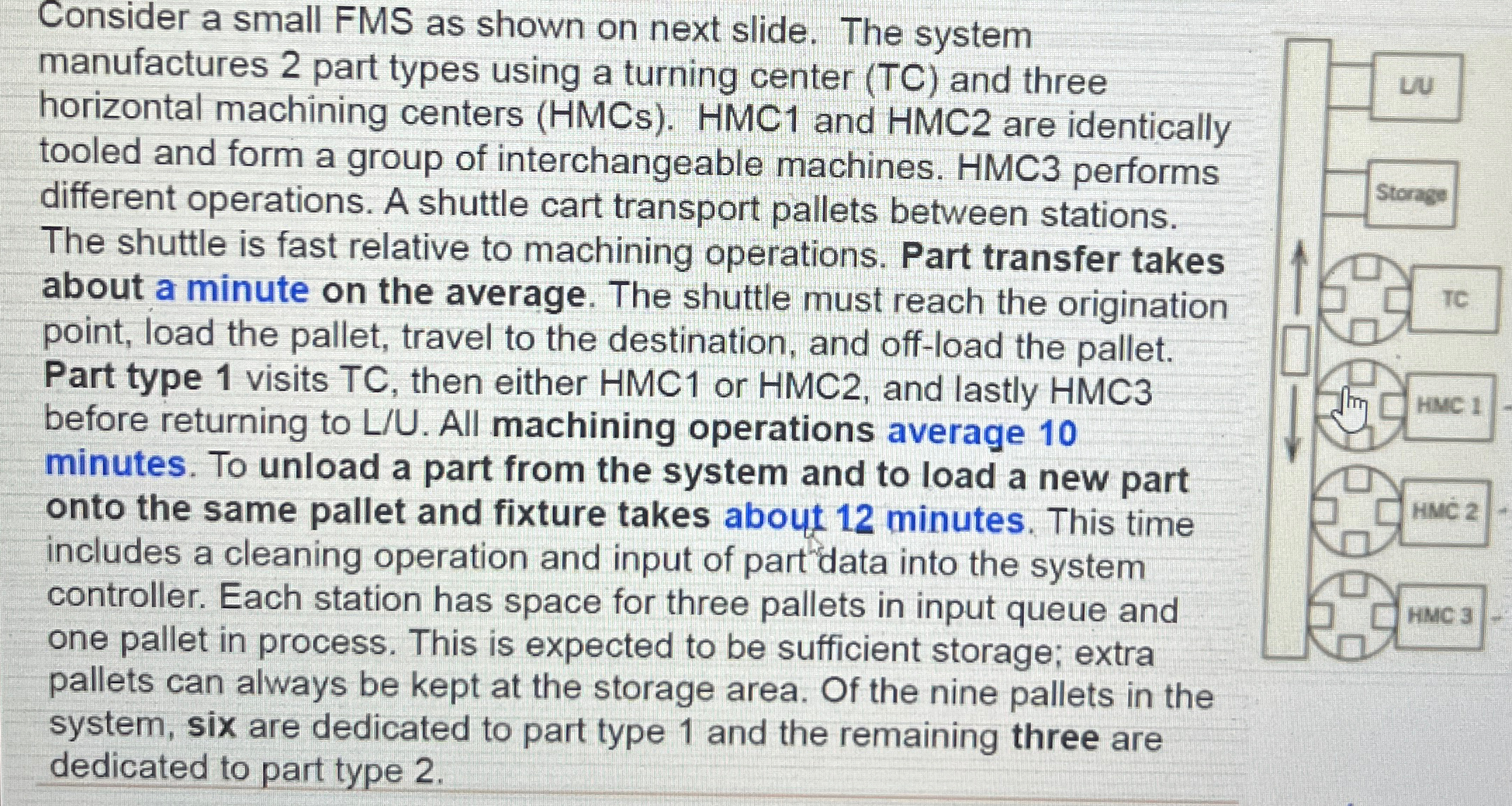

Question: Consider a small FMS as shown on next slide. The system manufactures 2 part types using a turning center ( TC ) and three horizontal

Consider a small FMS as shown on next slide. The system manufactures part types using a turning center TC and three horizontal machining centers HMCs HMC and HMC are identically tooled and form a group of interchangeable machines. HMC performs different operations. A shuttle cart transport pallets between stations. The shuttle is fast relative to machining operations. Part transfer takes about a minute on the average. The shuttle must reach the origination point, load the pallet, travel to the destination, and offload the pallet. Part type visits TC then either HMC or HMC and lastly HMC before returning to All machining operations average minutes. To unload a part from the system and to load a new part onto the same pallet and fixture takes about minutes. This time includes a cleaning operation and input of part data into the system controller. Each station has space for three pallets in input queue and one pallet in process. This is expected to be sufficient storage; extra pallets can always be kept at the storage area. Of the nine pallets in the system, six are dedicated to part type and the remaining three are dedicated to part type

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock