Question: Consider an inventory system that is continuously reviewed. Each time the inventory position drops below the reorder point, R, an order is placed. The

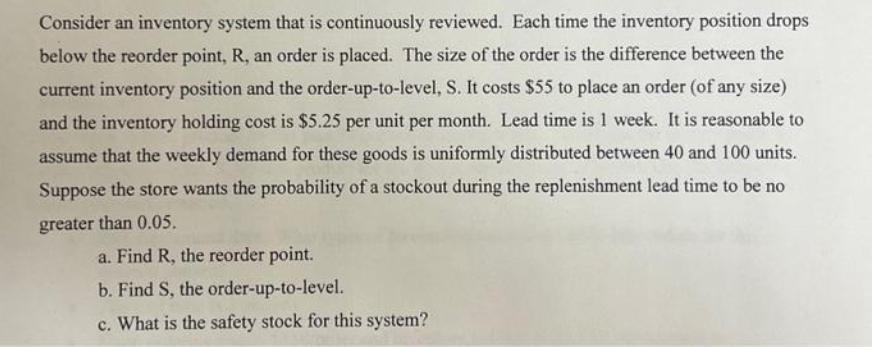

Consider an inventory system that is continuously reviewed. Each time the inventory position drops below the reorder point, R, an order is placed. The size of the order is the difference between the current inventory position and the order-up-to-level, S. It costs $55 to place an order (of any size) and the inventory holding cost is $5.25 per unit per month. Lead time is 1 week. It is reasonable to assume that the weekly demand for these goods is uniformly distributed between 40 and 100 units. Suppose the store wants the probability of a stockout during the replenishment lead time to be no greater than 0.05. a. Find R, the reorder point. b. Find S, the order-up-to-level. c. What is the safety stock for this system?

Step by Step Solution

3.27 Rating (150 Votes )

There are 3 Steps involved in it

To find the reorder point R we need to calculate the average demand during the lead time and add a s... View full answer

Get step-by-step solutions from verified subject matter experts