Question: *Continued - Allow Varying Inventory Do not take into account any hiring or layoff cost for the first period Plan C Level Strategy at a

*Continued - Allow Varying Inventory

Do not take into account any hiring or layoff cost for the first period

Plan C

Level Strategy at a constant rate of 1300

Allow Varying inventory

Obtain the remainder from overtime

Do not take into account of any hiring or lay off cost for the first period

Which plan is more economical plan for Eagle Fabrication

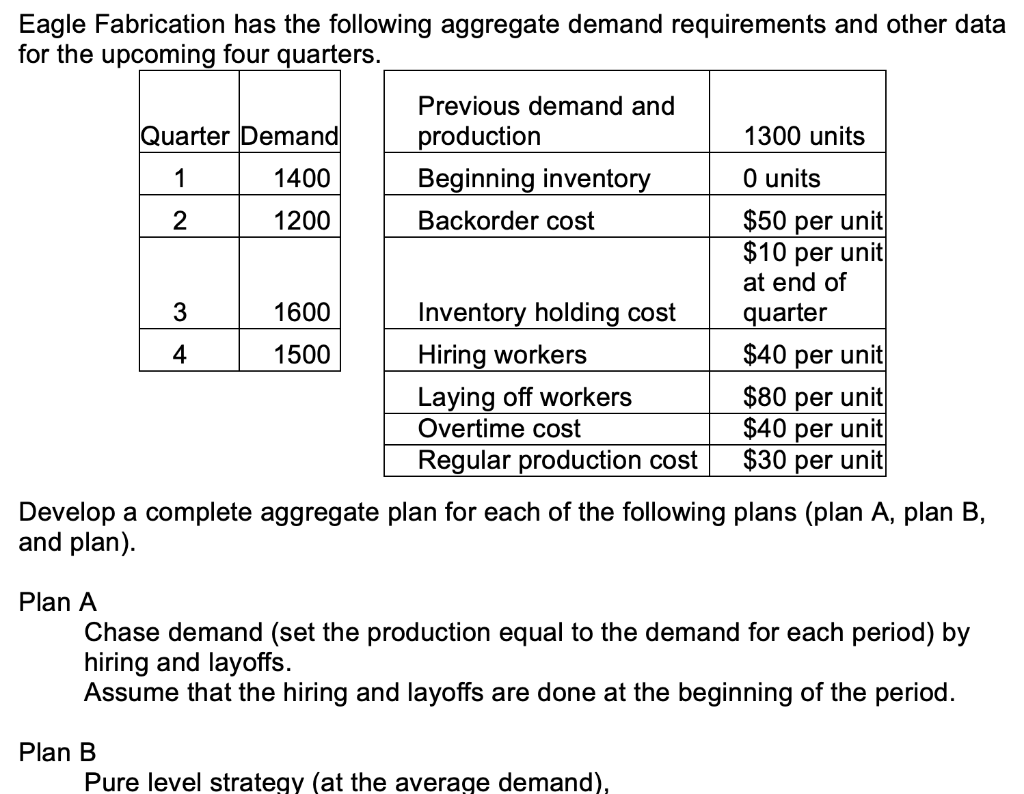

Eagle Fabrication has the following aggregate demand requirements and other data for the upcoming four quarters. Previous demand and Quarter Demand production 1300 units 1 1400 Beginning inventory 0 units 2 1200 Backorder cost $50 per unit $10 per unit at end of 3 1600 Inventory holding cost quarter 4 1500 Hiring workers $40 per unit Laying off workers $80 per unit Overtime cost $40 per unit Regular productic cost $30 per unit Develop a complete aggregate plan for each of the following plans (plan A, plan B, and plan). Plan A Chase demand (set the production equal to the demand for each period) by hiring and layoffs. Assume that the hiring and layoffs are done at the beginning of the period. Plan B Pure level strategy (at the average demand)Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts