Question: (Continued from Problem 6) Dana Johnson Corp was just notified that -- the estimated demands should be revised to: 250 units, 220 units, and 375

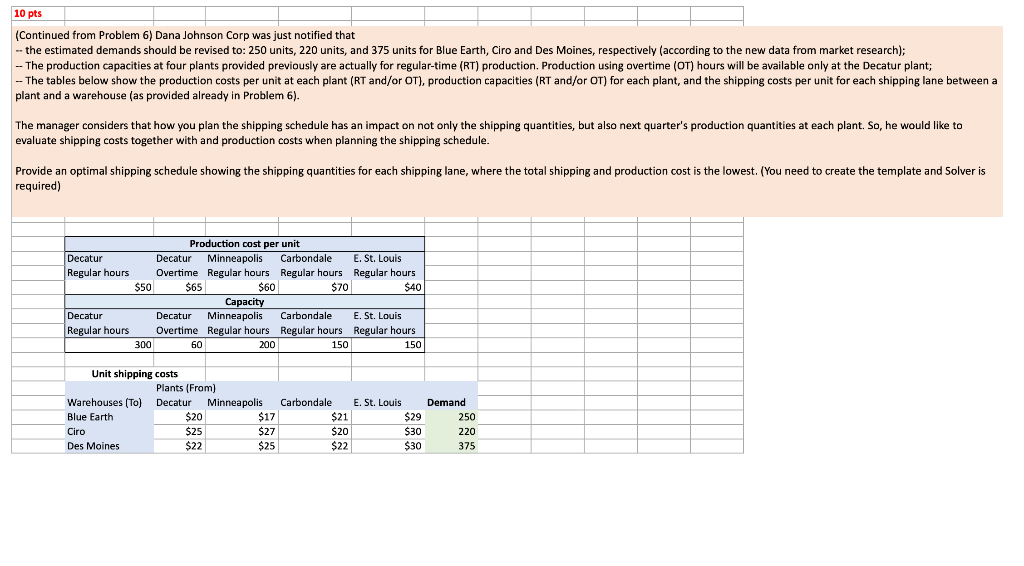

(Continued from Problem 6) Dana Johnson Corp was just notified that -- the estimated demands should be revised to: 250 units, 220 units, and 375 units for Blue Earth, Ciro and Des Moines, respectively (according to the new data from market research); - The production capacities at four plants provided previously are actually for regular-time (RT) production. Production using overtime (OT) hours will be available only at the Decatur plant; - The tables below show the production costs per unit at each plant (RT and/or OT), production capacities (RT and/or OT) for each plant, and the shipping costs per unit for each shipping lane between a plant and a warehouse (as provided already in Problem 6). The manager considers that how you plan the shipping schedule has an impact on not only the shipping quantities, but also next quarter's production quantities at each plant. So, he would like to evaluate shipping costs together with and production costs when planning the shipping schedule. Provide an optimal shipping schedule showing the shipping quantities for each shipping lane, where the total shipping and production cost is the lowest. (You need to create the template and Solver is required)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts