Question: Cool Systems manufactures an optical switch that it uses in its final product. The switch has the following manufacturing costs per unit: Another company has

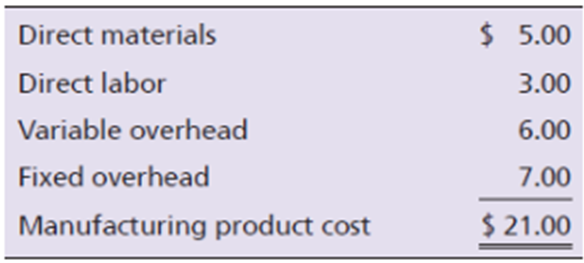

Cool Systems manufactures an optical switch that it uses in its final product. The switch has the following manufacturing costs per unit:

Another company has offered to sell Cool Systems the switch for 515.00 per unit. If Cool Systems buys the switch from the outside supplier, the idle manufacturing facilities cannot be used for any other purpose, yet none of the fixed costs are avoidable. Prepare an outsourcing analysis to determine whether Cool Systems should make or buy the switch.

Direct materials Direct labor Variable overhead Fixed overhead Manufacturing product cost $ 5.00 3.00 6.00 7.00 $ 21.00

Step by Step Solution

3.40 Rating (141 Votes )

There are 3 Steps involved in it

To determine whether Cool Systems should make or buy the switch we need to compare the relevant costs of manufacturing the switch inhouse versus purchasing it from an outside supplier MakeorBuy Analysis Step 1 Analyze InHouse Manufacturing Costs Direct Materials 500 per unit Direct Labor 300 per unit Variable Overhead 600 per unit Fixed Overhead 700 per unit not avoidable if not producing Total Cost of Manufacturing InHouse textTotal InHouse Cost textDirect Materials textDirect Labor textVariable Overhead textFixed Overhead textTotal InHouse Cost 5 3 6 7 21 text per unit Step 2 Analyze Outsourcing Costs Cost from Supplier 1500 per unit Step 3 Compare Relevant Costs When deciding to make or buy only the costs directly affected by the decision relevant costs should be considered Relevant Costs for InHouse Production Direct Materials 500 Direct Labor 300 Variable Overhead 600 Total Relevant InHouse Costs 5 3 6 14 text per unit The fixed overhead is not avoidable and therefore is not a relevant cost ... View full answer

Get step-by-step solutions from verified subject matter experts