Question: Could I get help on these please Question 1 (4 points): A company makes scissors in 2-inch, 4-inch, 6-inch, and 8-inch. They make each in

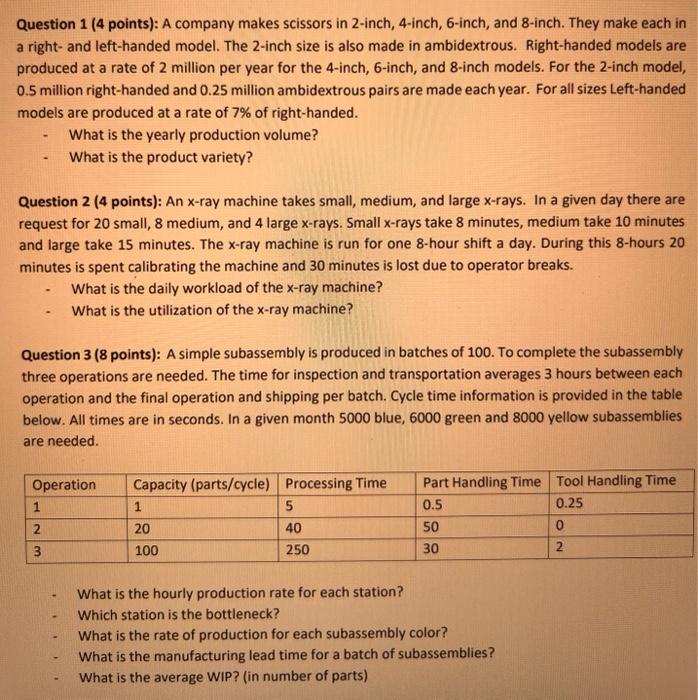

Question 1 (4 points): A company makes scissors in 2-inch, 4-inch, 6-inch, and 8-inch. They make each in a right- and left-handed model. The 2 -inch size is also made in ambidextrous. Right-handed models are produced at a rate of 2 million per year for the 4 -inch, 6 -inch, and 8 -inch models. For the 2 -inch model, 0.5 million right-handed and 0.25 million ambidextrous pairs are made each year. For all sizes Left-handed models are produced at a rate of 7% of right-handed. - What is the yearly production volume? - What is the product variety? Question 2 ( 4 points): An x-ray machine takes small, medium, and large x-rays. In a given day there are request for 20 small, 8 medium, and 4 large x-rays. Small x-rays take 8 minutes, medium take 10 minutes and large take 15 minutes. The x-ray machine is run for one 8 -hour shift a day. During this 8 -hours 20 minutes is spent calibrating the machine and 30 minutes is lost due to operator breaks. - What is the daily workload of the x-ray machine? - What is the utilization of the x-ray machine? Question 3 ( 8 points): A simple subassembly is produced in batches of 100 . To complete the subassembly three operations are needed. The time for inspection and transportation averages 3 hours between each operation and the final operation and shipping per batch. Cycle time information is provided in the table below. All times are in seconds. In a given month 5000 blue, 6000 green and 8000 yellow subassemblies are needed. - What is the hourly production rate for each station? - Which station is the bottleneck? - What is the rate of production for each subassembly color? - What is the manufacturing lead time for a batch of subassemblies? - What is the average WIP? (in number of parts)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts