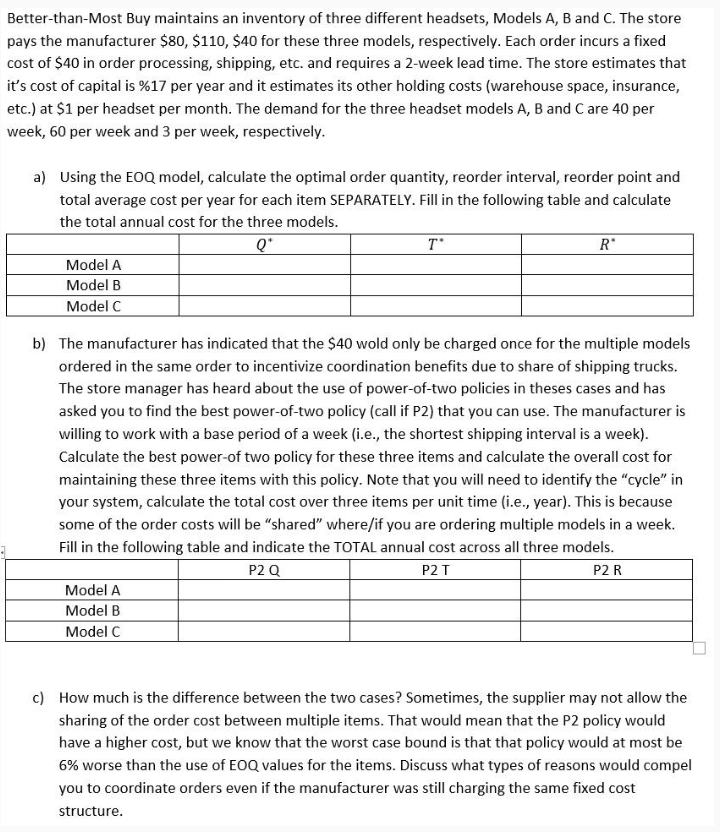

Question: Could people help me for b and c Better - than - Most Buy maintains an inventory of three different headsets, Models A , B

Could people help me for b and c BetterthanMost Buy maintains an inventory of three different headsets, Models A B and C The store

pays the manufacturer $$$ for these three models, respectively. Each order incurs a fixed

cost of $ in order processing, shipping, etc. and requires a week lead time. The store estimates that

it's cost of capital is per year and it estimates its other holding costs warehouse space, insurance,

etc. at $ per headset per month. The demand for the three headset models A B and C are per

week, per week and per week, respectively.

a Using the EOQ model, calculate the optimal order quantity, reorder interval, reorder point and

total average cost per year for each item SEPARATELY. Fill in the following table and calculate

the total annual cost for the three models.

b The manufacturer has indicated that the $ wold only be charged once for the multiple models

ordered in the same order to incentivize coordination benefits due to share of shipping trucks.

The store manager has heard about the use of poweroftwo policies in theses cases and has

asked you to find the best poweroftwo policy call if P that you can use. The manufacturer is

willing to work with a base period of a week ie the shortest shipping interval is a week

Calculate the best powerof two policy for these three items and calculate the overall cost for

maintaining these three items with this policy. Note that you will need to identify the "cycle" in

your system, calculate the total cost over three items per unit time ie year This is because

some of the order costs will be "shared" whereif you are ordering multiple models in a week.

Fill in the following table and indicate the TOTAL annual cost across all three models.

c How much is the difference between the two cases? Sometimes, the supplier may not allow the

sharing of the order cost between multiple items. That would mean that the P policy would

have a higher cost, but we know that the worst case bound is that that policy would at most be

worse than the use of EOQ values for the items. Discuss what types of reasons would compel

you to coordinate orders even if the manufacturer was still charging the same fixed cost

structure.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock