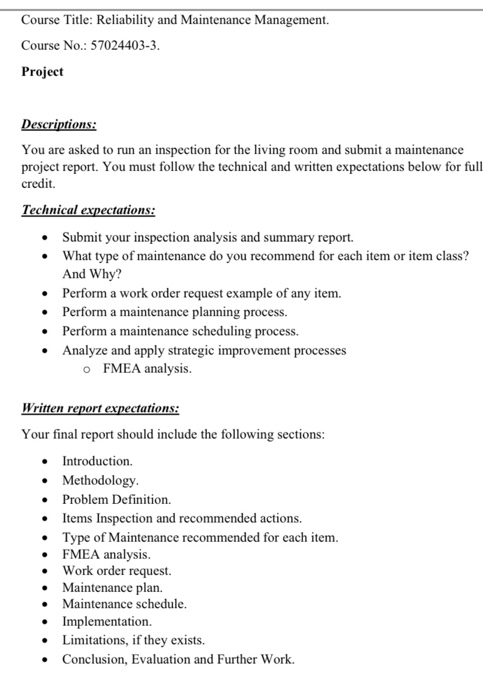

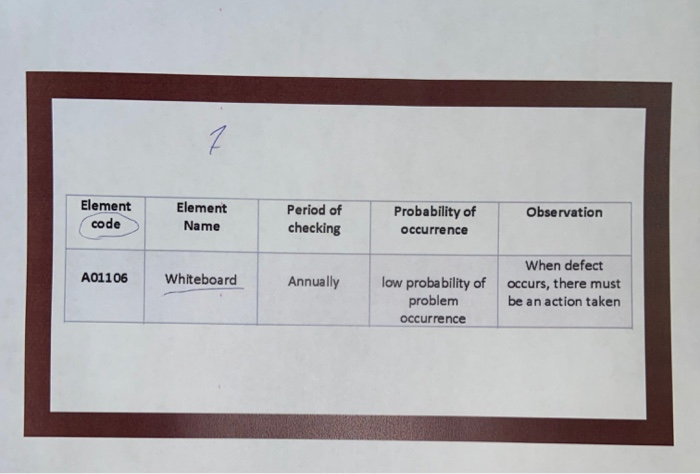

Question: Course Title: Reliability and Maintenance Management. Course No.: 57024403-3. Project Descriptions: You are asked to run an inspection for the living room and submit a

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock