Question: C(pk)= ?, C(p)=?, and the process is not centered or variability is too large? Canine Gourmet Super Breath dog treats are sold in boxes labeled

C(pk)= ?, C(p)=?, and the process is not centered or variability is too large?

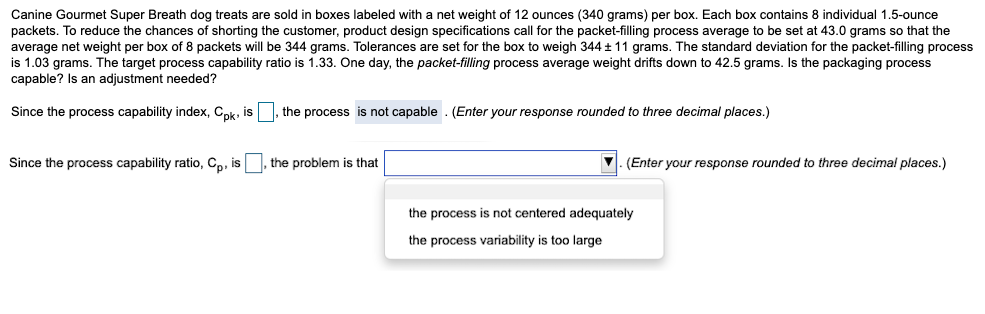

Canine Gourmet Super Breath dog treats are sold in boxes labeled with a net weight of 12 ounces (340 grams) per box. Each box contains 8 individual 1.5-ounce packets. To reduce the chances of shorting the customer, product design specifications call for the packet-filling process average to be set at 43.0 grams so that the average net weight per box 8 packets will be 344 grams. Tolerances are set for the box to weigh 344 : 11 grams. The standard deviation for the packet-filling process is 1.03 grams. The target process capability ratio is 1.33. One day, the packet-filling process average weight drifts down to 42.5 grams. Is the packaging process capable? Is an adjustment needed? Since the process capability index, Cpk, is , the process is not capable . (Enter your response rounded to three decimal places.) Since the process capability ratio, Cp, is the problem is that (Enter your response rounded to three decimal places.) the process is not centered adequately the process variability is too largeStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock