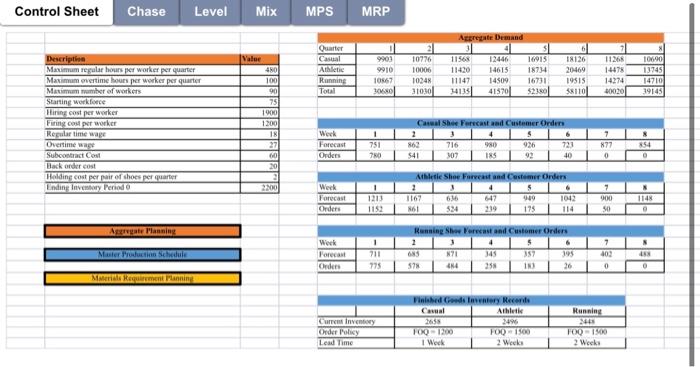

Question: create master production schedule using information below Control Sheet Chase Level Mix MPS MRP Aggregate Demand Quarter 10690 13745 Athletic Running Total 9900 9910 10567

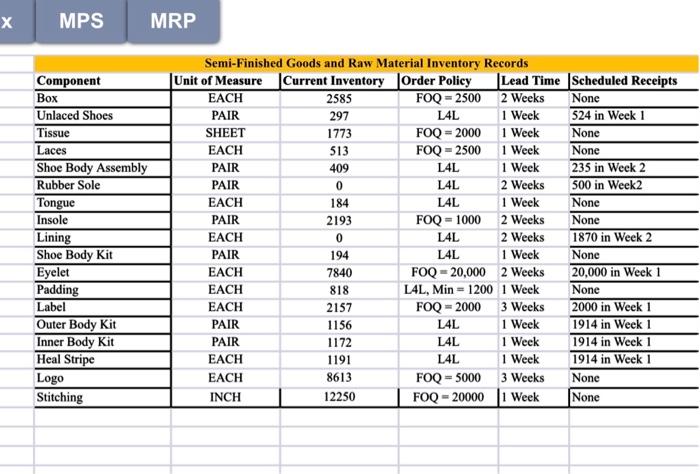

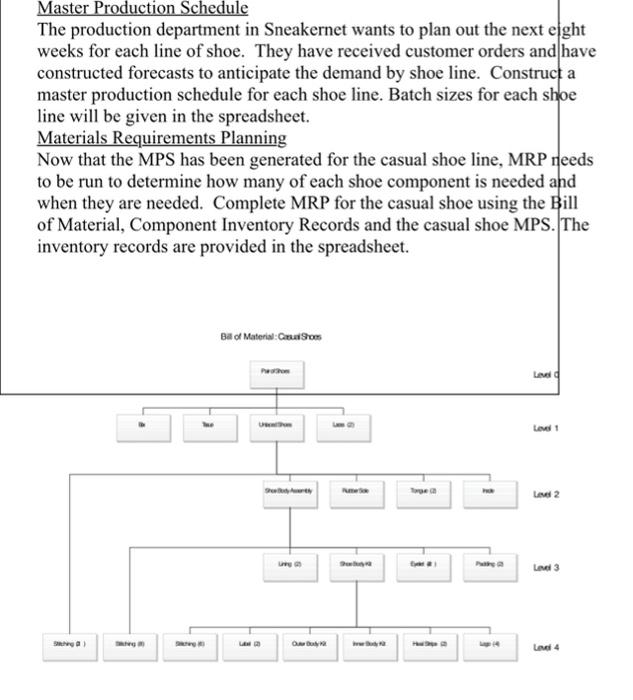

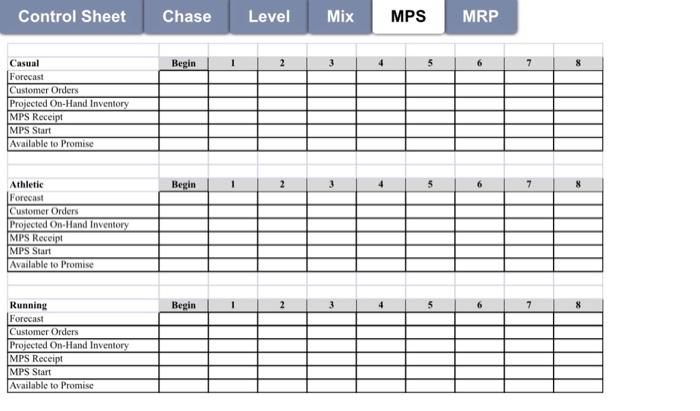

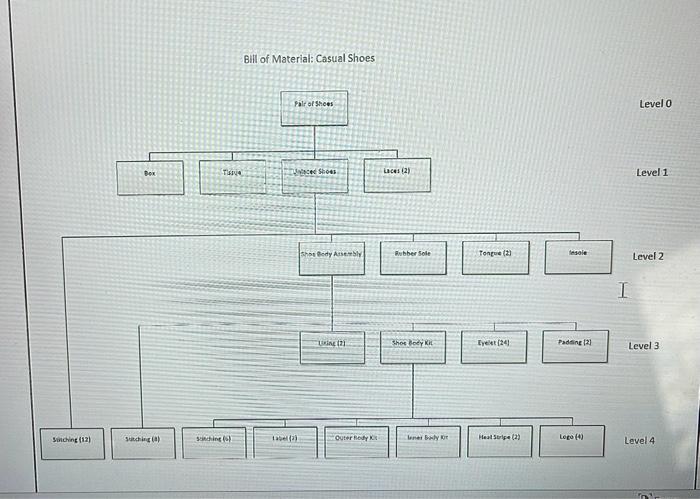

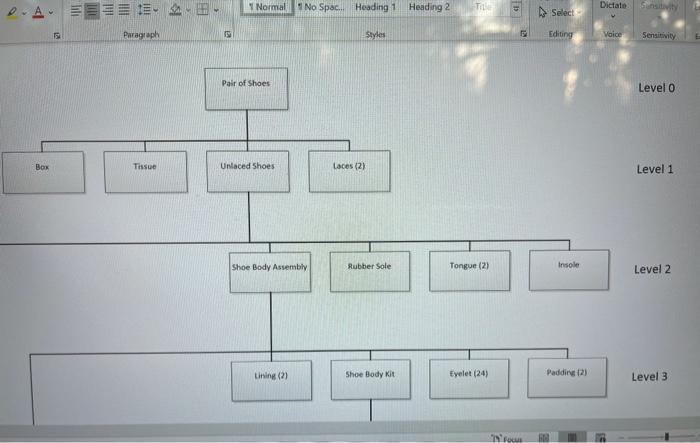

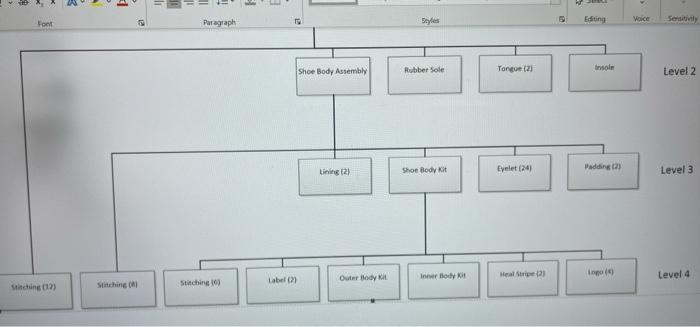

Control Sheet Chase Level Mix MPS MRP Aggregate Demand Quarter 10690 13745 Athletic Running Total 9900 9910 10567 360 10776 10006 1024 31010 11565 11420 11147 34135 12446 14615 14509 415701 16915 18734 16731 18126 20469 19515 58110 1126 14678 14274 20020 14710 39145 Description Maximum regular hours per worker per quarter Maximam overtime hours per worker per quarter Maximumumber of workers Starting workforce Hiring cost per worker Firing cost per worker Regular time wage Overtime wage Subcontract Cost Hack Order cost Holding cost per pair of shoes per quarter Ending Inventy Perindo Value 480 100 90 75 1900 1200 18 27 60 20 Werk Forecast Orders 1 751 70 Chat She Fed Customer Orders 2 3 4 862 716980 936 721 307 185 92 40 7 877 0 854 2200 1 Werk Forecast Orders Atletic Shoe Forest and Cestemer Orders 2 6 1167 647 949 1042 361 534 175 7 900 50 1148 Arte llam Running 1 1 3 Work Forecast Onders Vorecast and Customer Orders 6 357 7 403 0 UN 0 775 578 Maguirement Planne Running Current VENY Order Policy Lead Time Finished Goods Tantery Recente Athletic 24 1001200 FO01500 1 Week 2 Weeks FOO 100 2 Weeks MPS MRP 409 Component Box Unlaced Shoes Tissue Laces Shoe Body Assembly Rubber Sole Tongue Insole Lining Shoe Body Kit Eyelet Padding Label Outer Body Kit Inner Body Kit Heal Stripe Logo Stitching Semi-Finished Goods and Raw Material Inventory Records Unit of Measure Current Inventory Order Policy Lead Time Scheduled Receipts EACH 2585 FOQ = 2500 2 Weeks None PAIR 297 L4L 1 Week 524 in Week 1 SHEET 1773 FOQ - 2000 1 Week None EACH 513 FOQ - 2500 1 Week None PAIR L4L 1 Week 235 in Week PAIR 0 L4L 2 Weeks 500 in Week 2 EACH 184 L4L 1 Week None PAIR 2193 FOQ = 1000 2 Weeks None EACH 0 2 Weeks 1870 in Week 2 PAIR 194 L4L 1 Week None EACH 7840 FOQ = 20,000 2 Weeks 20,000 in Week 1 EACH 818 L4L, Min = 1200 1 Week None EACH 2157 FOQ = 2000 3 Weeks 2000 in Week 1 PAIR 1156 L4L 1 Week 1914 in Week 1 PAIR 1172 L4L 1 Week 1914 in Week 1 EACH 1191 L4L 1 Week 1914 in Week 1 EACH 8613 FOQ = 5000 3 Weeks None INCH 12250 FOQ - 20000 1 Week None LAL Master Production Schedule The production department in Sneakernet wants to plan out the next eight weeks for each line of shoe. They have received customer orders and have constructed forecasts to anticipate the demand by shoe line. Construct a master production schedule for each shoe line. Batch sizes for each shoe line will be given in the spreadsheet. Materials Requirements Planning Now that the MPS has been generated for the casual shoe line, MRP needs to be run to determine how many of each shoe component is needed and when they are needed. Complete MRP for the casual shoe using the Bill of Material, Component Inventory Records and the casual shoe MPS. The inventory records are provided in the spreadsheet. Ba of Material: Colom Low1 1 Lad 2 Lad 3 OB LA 4 Control Sheet Chase Level Mix MPS MRP Begin 2 3 Casual Forecast Customer Orders Projected On-Hand Inventory MPS Receipt MPS Start Available to Promise Begin Athletic Forecast Customer Orders Projected On Hand Inventory MPS Receipt MPS Start Available to Promise Begin Running Forecast Customer Orders Projected On-Hand Inventory MPS Receipt MPS Start Available to Promise Bill of Material: Casual Shoes Palrol Shoes Level o BOK TIS Bed Shoes Laces (2) Level 1 Shoe Body Are Rubber Sole Tongue (20 Level 2 I U 121 Shoe Body Kit Eyes (24) Pading 121 Level 3 Stricing (12) Suitching) Saching Outer Hedy Laneye Heat Stripe (2) Lepo (4) Level 4 SE 1E Normal No Spac.. Heading 1 Heading 2 TIL Dictate Select 15 Paragraph 19 Styles Editing Voice Sensitivity Pair of Shoes Level o Tissue Unlaced Shoes Laces (2) Level 1 Shoe Body Assembly Rubber Sole Tongue (2) Insole Level 2 Lining (2) Shoe Body Kit Eyelet (24) Paddin (2) Level 3 Nos = 3 w Paragraph Font Editing Voice Servy Shoe Body Assembly Rubber Sole insole Tongue (2) Level 2 Lining (2) Shoe Body Kit Eyelet (24) Padding 123 Level 3 HealStripe Inner Body Level 4 Outer Body Kit Label1 ding 0123 Stitching Stitching Control Sheet Chase Level Mix MPS MRP Aggregate Demand Quarter 10690 13745 Athletic Running Total 9900 9910 10567 360 10776 10006 1024 31010 11565 11420 11147 34135 12446 14615 14509 415701 16915 18734 16731 18126 20469 19515 58110 1126 14678 14274 20020 14710 39145 Description Maximum regular hours per worker per quarter Maximam overtime hours per worker per quarter Maximumumber of workers Starting workforce Hiring cost per worker Firing cost per worker Regular time wage Overtime wage Subcontract Cost Hack Order cost Holding cost per pair of shoes per quarter Ending Inventy Perindo Value 480 100 90 75 1900 1200 18 27 60 20 Werk Forecast Orders 1 751 70 Chat She Fed Customer Orders 2 3 4 862 716980 936 721 307 185 92 40 7 877 0 854 2200 1 Werk Forecast Orders Atletic Shoe Forest and Cestemer Orders 2 6 1167 647 949 1042 361 534 175 7 900 50 1148 Arte llam Running 1 1 3 Work Forecast Onders Vorecast and Customer Orders 6 357 7 403 0 UN 0 775 578 Maguirement Planne Running Current VENY Order Policy Lead Time Finished Goods Tantery Recente Athletic 24 1001200 FO01500 1 Week 2 Weeks FOO 100 2 Weeks MPS MRP 409 Component Box Unlaced Shoes Tissue Laces Shoe Body Assembly Rubber Sole Tongue Insole Lining Shoe Body Kit Eyelet Padding Label Outer Body Kit Inner Body Kit Heal Stripe Logo Stitching Semi-Finished Goods and Raw Material Inventory Records Unit of Measure Current Inventory Order Policy Lead Time Scheduled Receipts EACH 2585 FOQ = 2500 2 Weeks None PAIR 297 L4L 1 Week 524 in Week 1 SHEET 1773 FOQ - 2000 1 Week None EACH 513 FOQ - 2500 1 Week None PAIR L4L 1 Week 235 in Week PAIR 0 L4L 2 Weeks 500 in Week 2 EACH 184 L4L 1 Week None PAIR 2193 FOQ = 1000 2 Weeks None EACH 0 2 Weeks 1870 in Week 2 PAIR 194 L4L 1 Week None EACH 7840 FOQ = 20,000 2 Weeks 20,000 in Week 1 EACH 818 L4L, Min = 1200 1 Week None EACH 2157 FOQ = 2000 3 Weeks 2000 in Week 1 PAIR 1156 L4L 1 Week 1914 in Week 1 PAIR 1172 L4L 1 Week 1914 in Week 1 EACH 1191 L4L 1 Week 1914 in Week 1 EACH 8613 FOQ = 5000 3 Weeks None INCH 12250 FOQ - 20000 1 Week None LAL Master Production Schedule The production department in Sneakernet wants to plan out the next eight weeks for each line of shoe. They have received customer orders and have constructed forecasts to anticipate the demand by shoe line. Construct a master production schedule for each shoe line. Batch sizes for each shoe line will be given in the spreadsheet. Materials Requirements Planning Now that the MPS has been generated for the casual shoe line, MRP needs to be run to determine how many of each shoe component is needed and when they are needed. Complete MRP for the casual shoe using the Bill of Material, Component Inventory Records and the casual shoe MPS. The inventory records are provided in the spreadsheet. Ba of Material: Colom Low1 1 Lad 2 Lad 3 OB LA 4 Control Sheet Chase Level Mix MPS MRP Begin 2 3 Casual Forecast Customer Orders Projected On-Hand Inventory MPS Receipt MPS Start Available to Promise Begin Athletic Forecast Customer Orders Projected On Hand Inventory MPS Receipt MPS Start Available to Promise Begin Running Forecast Customer Orders Projected On-Hand Inventory MPS Receipt MPS Start Available to Promise Bill of Material: Casual Shoes Palrol Shoes Level o BOK TIS Bed Shoes Laces (2) Level 1 Shoe Body Are Rubber Sole Tongue (20 Level 2 I U 121 Shoe Body Kit Eyes (24) Pading 121 Level 3 Stricing (12) Suitching) Saching Outer Hedy Laneye Heat Stripe (2) Lepo (4) Level 4 SE 1E Normal No Spac.. Heading 1 Heading 2 TIL Dictate Select 15 Paragraph 19 Styles Editing Voice Sensitivity Pair of Shoes Level o Tissue Unlaced Shoes Laces (2) Level 1 Shoe Body Assembly Rubber Sole Tongue (2) Insole Level 2 Lining (2) Shoe Body Kit Eyelet (24) Paddin (2) Level 3 Nos = 3 w Paragraph Font Editing Voice Servy Shoe Body Assembly Rubber Sole insole Tongue (2) Level 2 Lining (2) Shoe Body Kit Eyelet (24) Padding 123 Level 3 HealStripe Inner Body Level 4 Outer Body Kit Label1 ding 0123 Stitching Stitching

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts