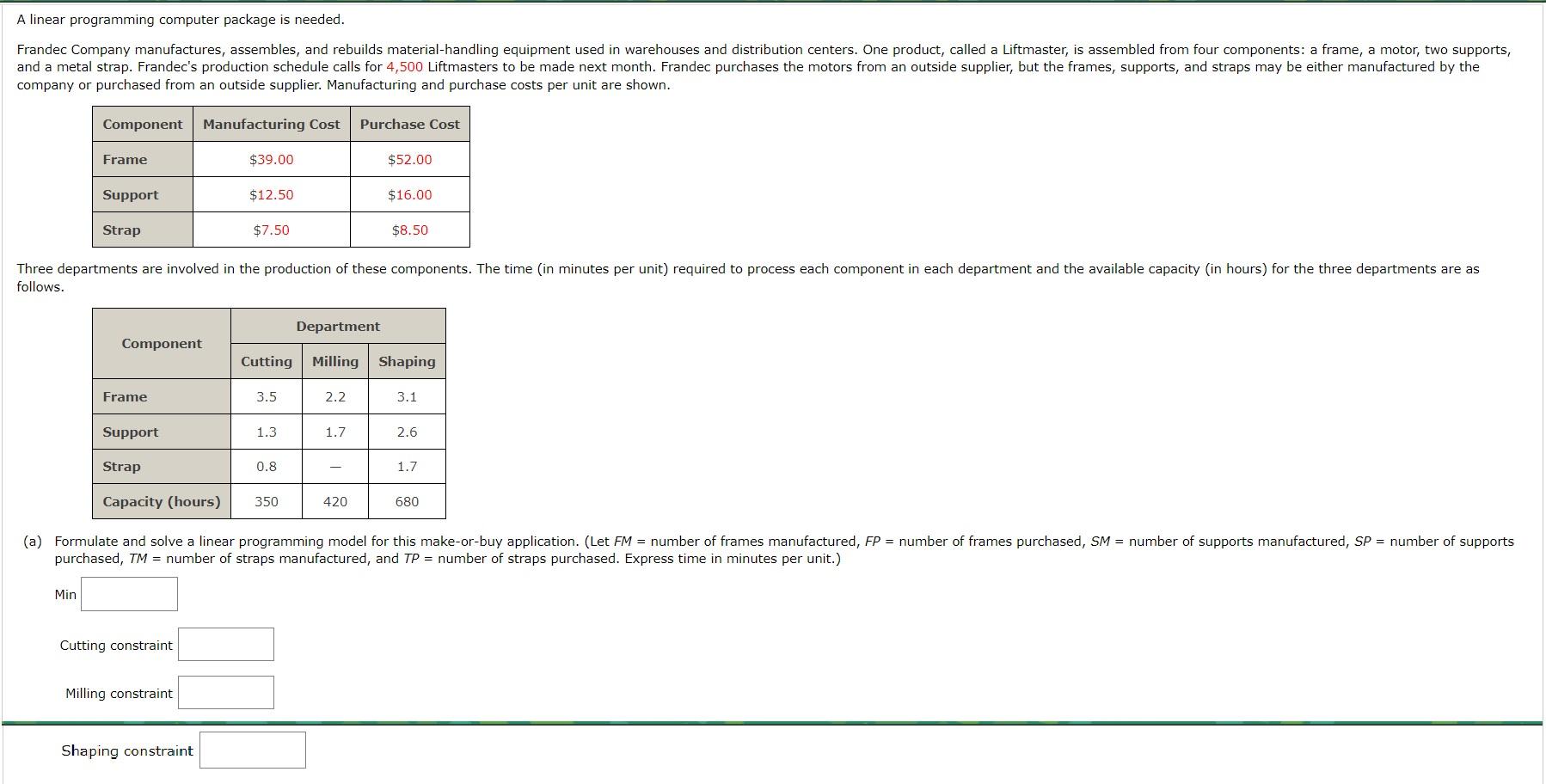

Question: Cutting constraint Milling constraint Shaping constraint Frame constraint Support constraint Strap constraint FM, FP, SM, SP, TM, TP 0 How many of each component should

Cutting constraint

Milling constraint

Shaping constraint

Frame constraint

Support constraint

Strap constraint

FM, FP, SM, SP, TM, TP 0

How many of each component should be manufactured and how many should be purchased? (Round your answers to the nearest whole number.)

(FM, FP, SM, SP, TM, TP) =

(b)

What is the total cost (in $) of the manufacturing and purchasing plan?

$

(c)

How many hours of production time are used in each department? (Round your answers to two decimal places.)

Cutting hrs

Milling hrs

Shaping hrs

(d)

How much (in $) should Frandec be willing to pay for an additional hour of time in the shaping department?

$

(e)

Another manufacturer has offered to sell frames to Frandec for $45 each. Could Frandec improve its position by pursuing this opportunity? Why or why not? (Round your answer to three decimal places.)

The reduced cost of _____ indicates that the solution ---Select--- can cannot be improved.

A linear programming computer package is needed. company or purchased from an outside supplier. Manufacturing and purchase costs per unit are shown. follows. purchased, TM= number of straps manufactured, and TP= number of straps purchased. Express time in minutes per unit.) Min Cutting constraint Milling constraint

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts