Question: Data for a regenerative vapor power cycle using an open and a closed feedwater heater, similar in design to that shown in the figure below,

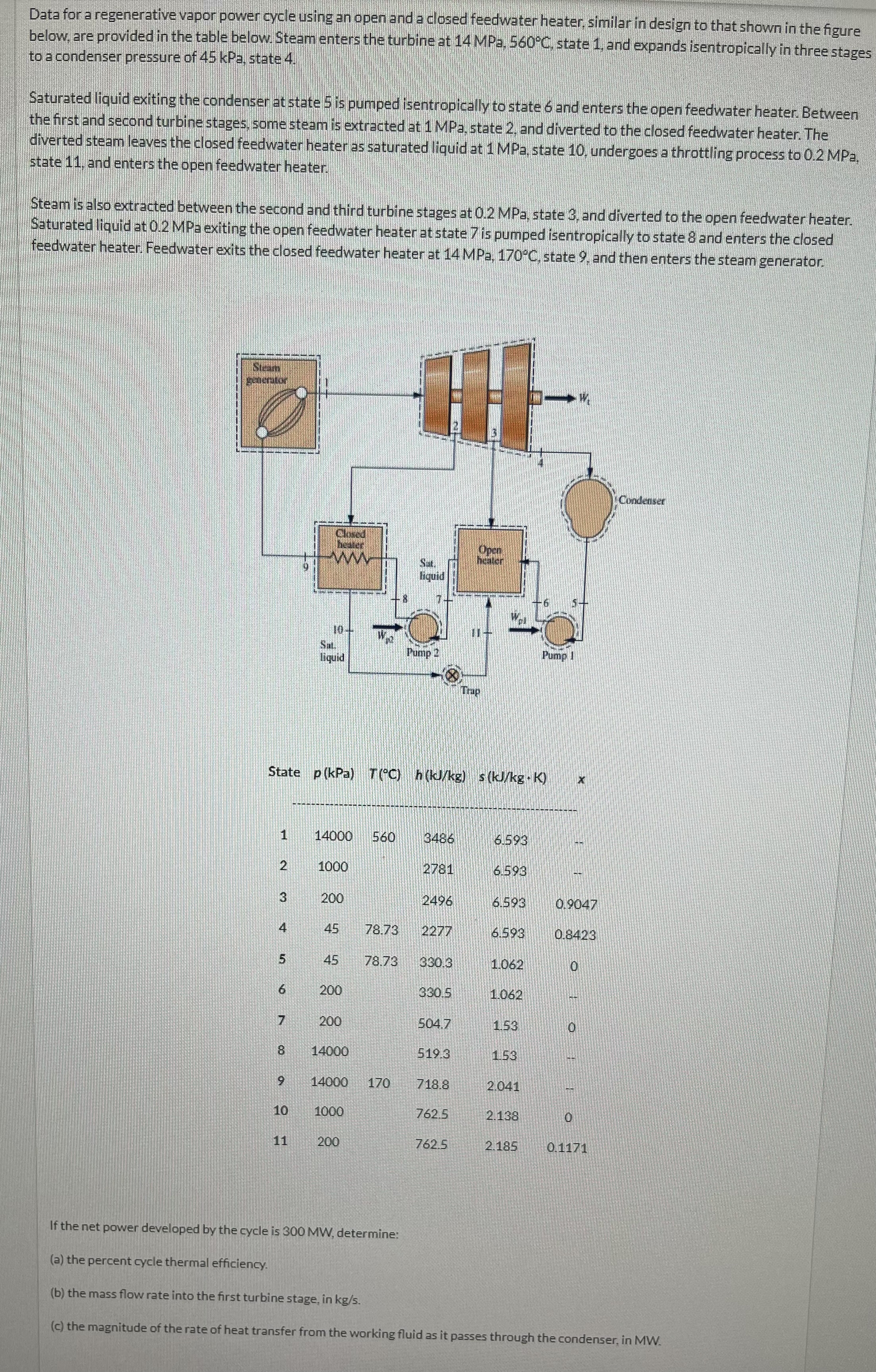

Data for a regenerative vapor power cycle using an open and a closed feedwater heater, similar in design to that shown in the figure below, are provided in the table below. Steam enters the turbine at MPa, state and expands isentropically in three stages to a condenser pressure of kPa state

Saturated liquid exiting the condenser at state is pumped isentropically to state and enters the open feedwater heater. Between the first and second turbine stages, some steam is extracted at MPa state and diverted to the closed feedwater heater. The diverted steam leaves the closed feedwater heater as saturated liquid at MPa state undergoes a throttling process to MPa state and enters the open feedwater heater.

Steam is also extracted between the second and third turbine stages at MPa state and diverted to the open feedwater heater. Saturated liquid at MPa exiting the open feedwater heater at state is pumped isentropically to state and enters the closed feedwater heater. Feedwater exits the closed feedwater heater at MPa, state and then enters the steam generator.

State

tabledots

Data for a regenerative vapor power cycle using an open and a closed feedwater heater, similar in design to that shown in the figure below, are provided in the table below. Steam enters the turbine at MPa, state and expands isentropically in three stages to a condenser pressure of kPa state

Saturated liquid exiting the condenser at state is pumped isentropically to state and enters the open feedwater heater. Between the first and second turbine stages, some steam is extracted at MPa state and diverted to the closed feedwater heater. The diverted steam leaves the closed feedwater heater as saturated liquid at MPa state undergoes a throttling process to MPa state and enters the open feedwater heater.

Steam is also extracted between the second and third turbine stages at MPa, state and diverted to the open feedwater heater. Saturated liquid at MPa exiting the open feedwater heater at state is pumped isentropically to state and enters the closed feedwater heater. Feedwater exits the closed feedwater heater at MPa, state and then enters the steam generator.

State

tabledots

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock