Question: DECISION PROBLEM 2: Capacity Planning to meet Uncertain Demand Reminder: Demand uncertainties are the root of all capacity planning challenges. Excess capacity results in waste

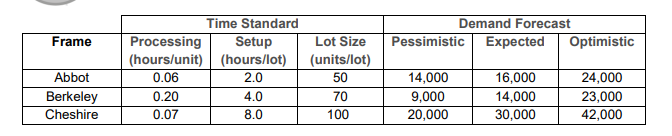

DECISION PROBLEM 2: Capacity Planning to meet Uncertain Demand Reminder: Demand uncertainties are the root of all capacity planning challenges. Excess capacity results in waste if equipment, inventory, or personnel are idle. Insufficient capacity results in the loss of business and the potential loss of sales to competitors who can meet customer demand. Olde World produces three different types of window frame profiles - the Abbot, the Berkeley, and the Cheshire. It is known that one specific machining center is the production bottleneck for all three frames. Olde World's production facility operates five days a week and has three 8-hour shifts. The facility is open for 50 weeks a year. Below are the time standards, lot sizes and demand forecasts for the Abbot, the Berkeley, and the Cheshire. Since there is always some uncertainty in demand, the fabrication manager considers three different forecasts ranging from pessimistic to expected to optimistic. The manager has determined that a 20% capacity cushion is optimal.

\f

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts